¶ Filament Not Sticking to the Bed

¶ Z-offset Adjust

It is very important that the first layer of your print is strongly connected to the printer’s build platform so that the remainder of your part can be built on this foundation.

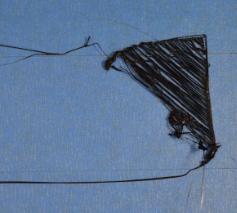

If the first layer is not sticking to the build platform, it will create problems later on. See the photo below, the first layer could not stick on the build plate. The photo below is a very classic common issue that the distance between the nozzle and build plate were way too far, so the filament could not stick to the build plate.

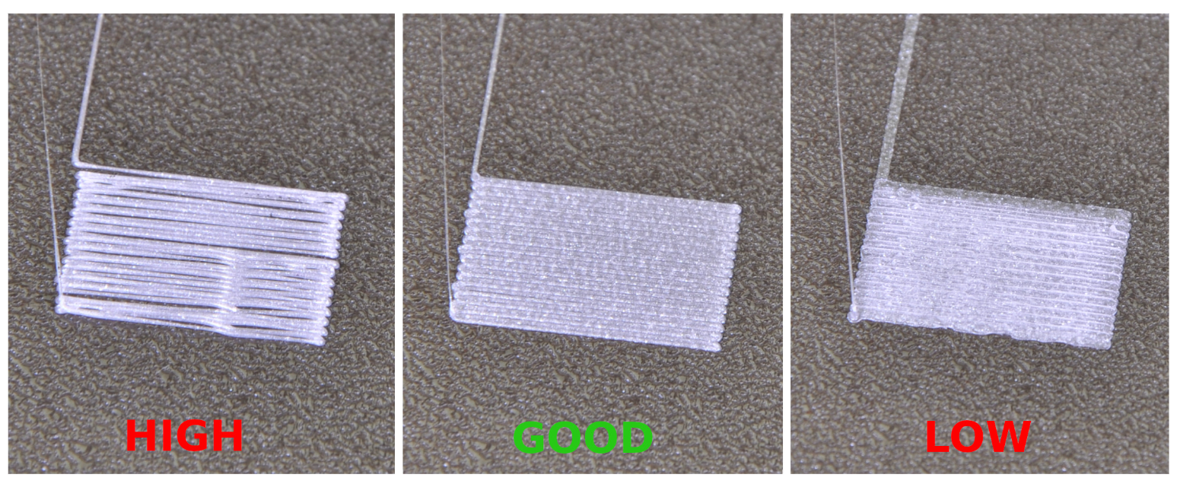

Here is the some example below shows how the correct first layer should looks like. The first one is too far from the bed, the second one is perfect, the third one is too close to the bed.

¶ Prescription

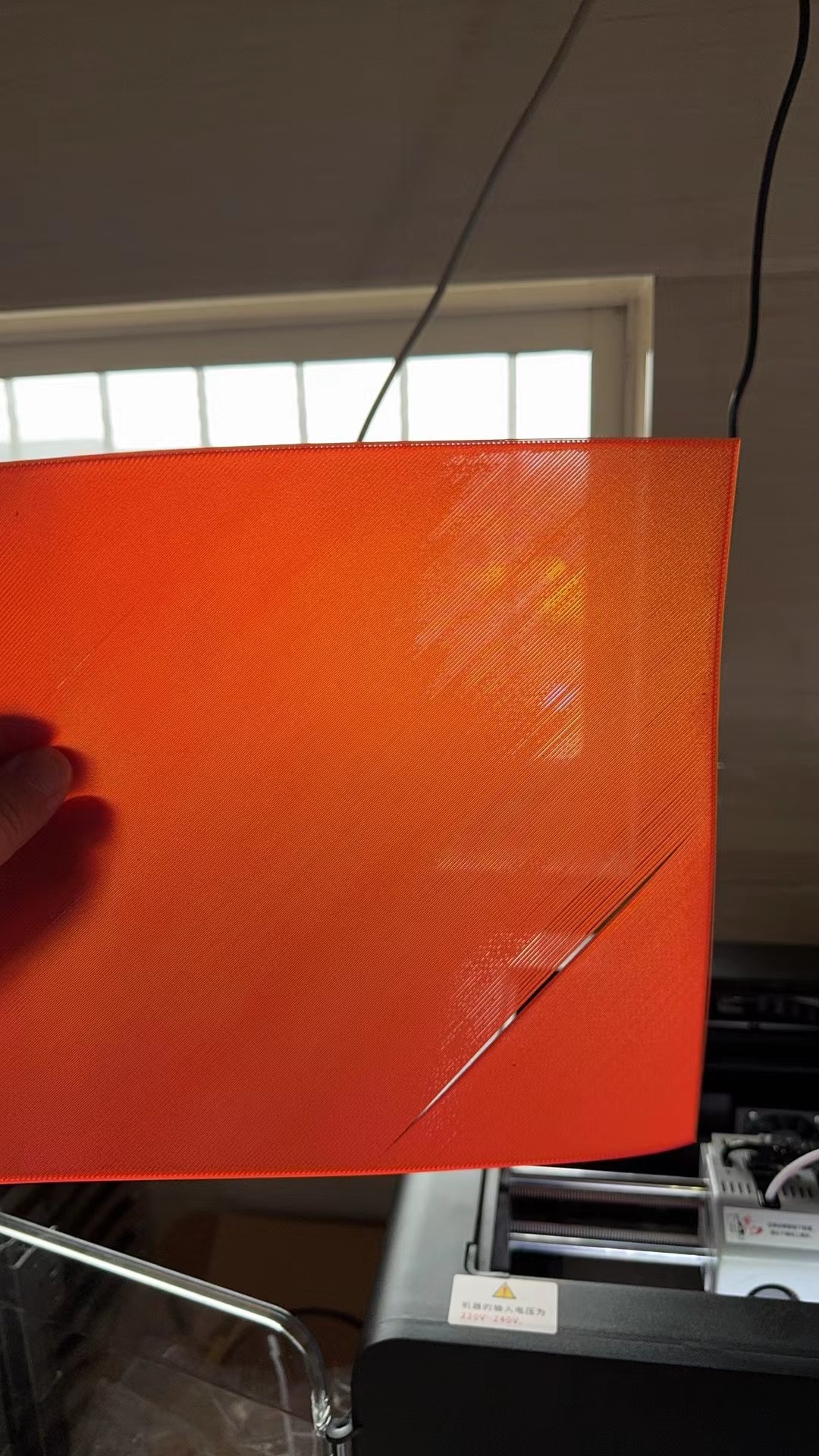

As shown in the figure below, if you encounter a gap between the first layer of lines during printing. This means that the distance between the nozzle and the build palte is too far, so you need to adjust the Z-offset of the printer.The Z-offset is the value of distance between the nozzle and build plate.

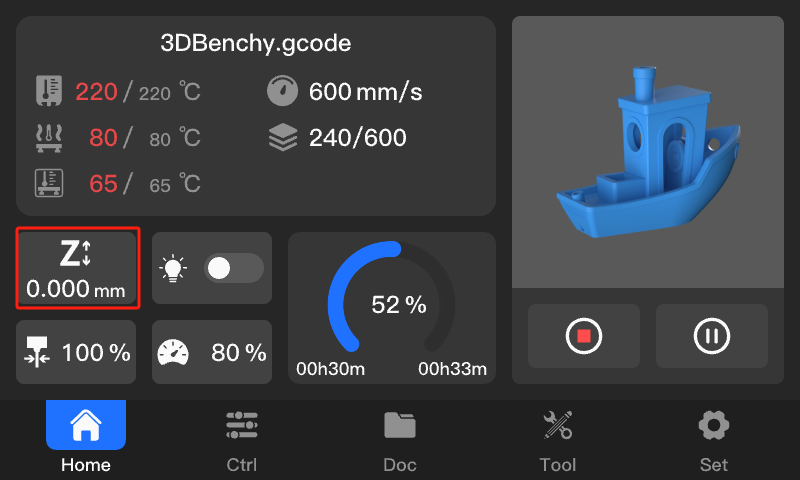

The best way to adjust the Z-offset is during the first layer printing, when the print head start to print the first layer, please click the Z-offset feature on the screen ( see the photo below, click Z icon), after you up the build plate or lower the build plate, it will have one second delay, so don't click to fast. You can start with the 0.05 value first, and see the change. The value will be saved after you adjust.

¶ Clean the Print Bed

A dirty or greasy print bed can cause adhesion problems. Clean the surface thoroughly before printing.

PEI beds: Use IPA or water to clean, as PEI is sensitive to oils.

Glue stick: A thin layer of a non-toxic glue stick can improve adhesion.

Hairspray: Some users spray a light coat of hairspray (usually a medium-hold kind) on the print bed for better adhesion.

If there is still a problem after platform calibration, please contact our after-sales staff, they will provide you with assistance.