This page introduces the main components of the Q2 3D printer and provides a general overview to help you understand how the printer works.

¶ How Does Q2 Work?

The Q2 3D printer uses plastic filament to create three-dimensional objects.

In most cases, the Q2 prints 3D models in STL format. Before printing, slicing software is required to process the model file.

Using QIDI Studio as an example, the slicing software divides the STL file into multiple layers. The data for each layer is then automatically converted into instructions the printer can understand. These instructions define the movement paths and speeds of each axis during the printing process.

In addition, the slicing software embeds various printing parameters into the generated code, such as filament temperature and extrusion speed, and can automatically generate supports for specific parts of the model when needed.

¶ Z-Axis

The Z-axis consists of four lead screws connected to a single stepper motor via a belt. This design ensures stable and synchronized vertical movement during printing.

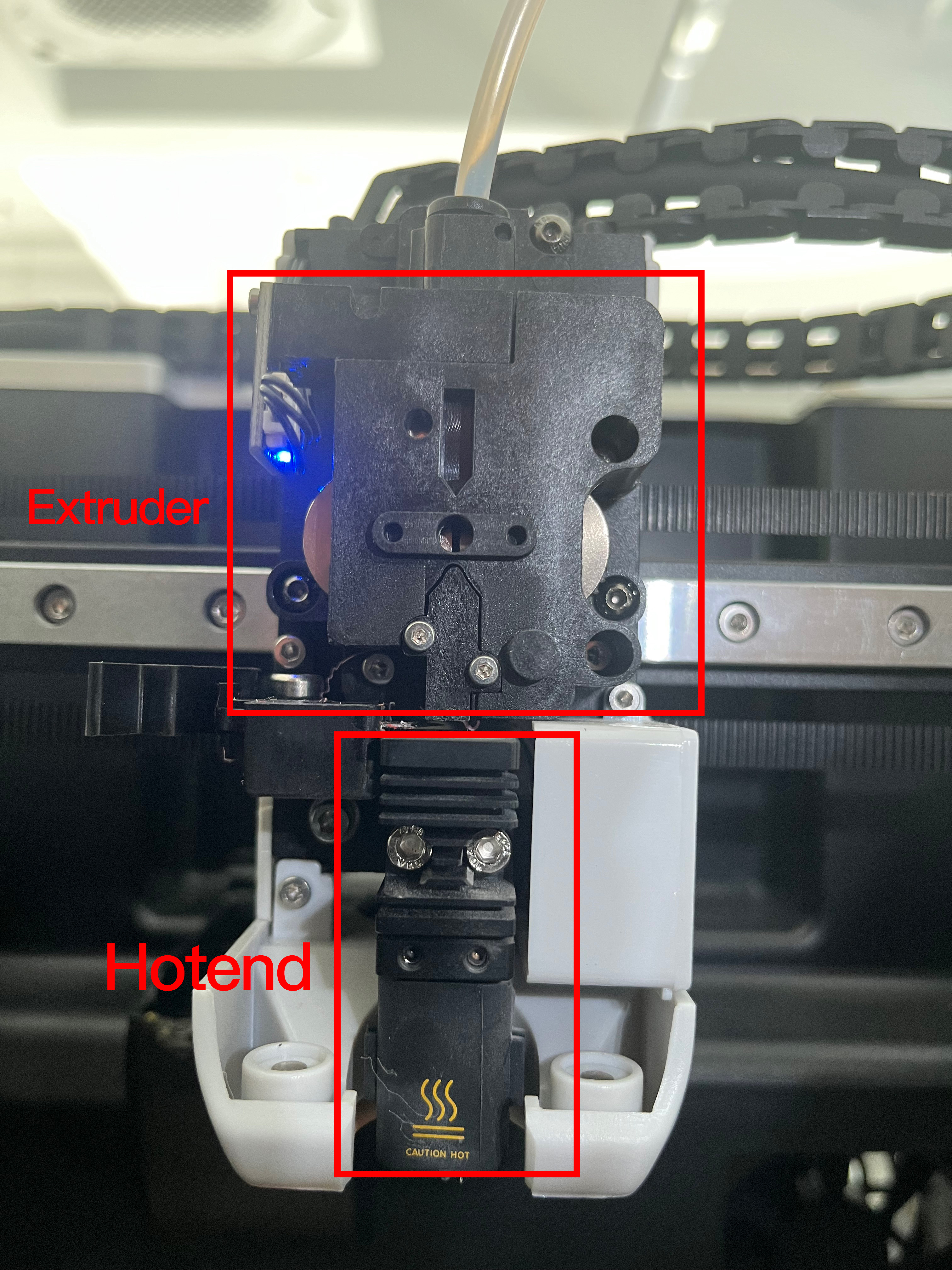

¶ Extruder

The extruder is responsible for pulling filament from the spool and feeding it into the hot end. After the filament is heated and melted, it is extruded through the nozzle to form the printed model.

Precise control of the filament feed length is essential for print quality, making the extruder one of the core components of the 3D printer.

¶ Hot End

The hot end is responsible for heating the filament to a specified temperature, melting it, and depositing it in thin layers to form the printed model. Different materials require different printing temperatures.

For example, PLA filament is typically printed at lower temperatures of approximately 210–220 °C, while materials such as PETG and ABS require higher temperatures, usually around 250–260 °C.

¶ Hot Bed

The hot bed heats the printing surface to improve adhesion between the first layer and the build plate.

When using the Q2 3D printer, the hot bed temperature is adjusted based on the filament type, with a maximum temperature of 110 °C. For example, PLA can be printed on a low-temperature build surface at 35–45 °C without warping. To prevent warping, materials such as ABS and PC typically require a hot bed temperature of 100–110 °C.

If the printing surface is not heated, the deposited filament will cool too quickly, and internal stress between layers may cause the print to warp.

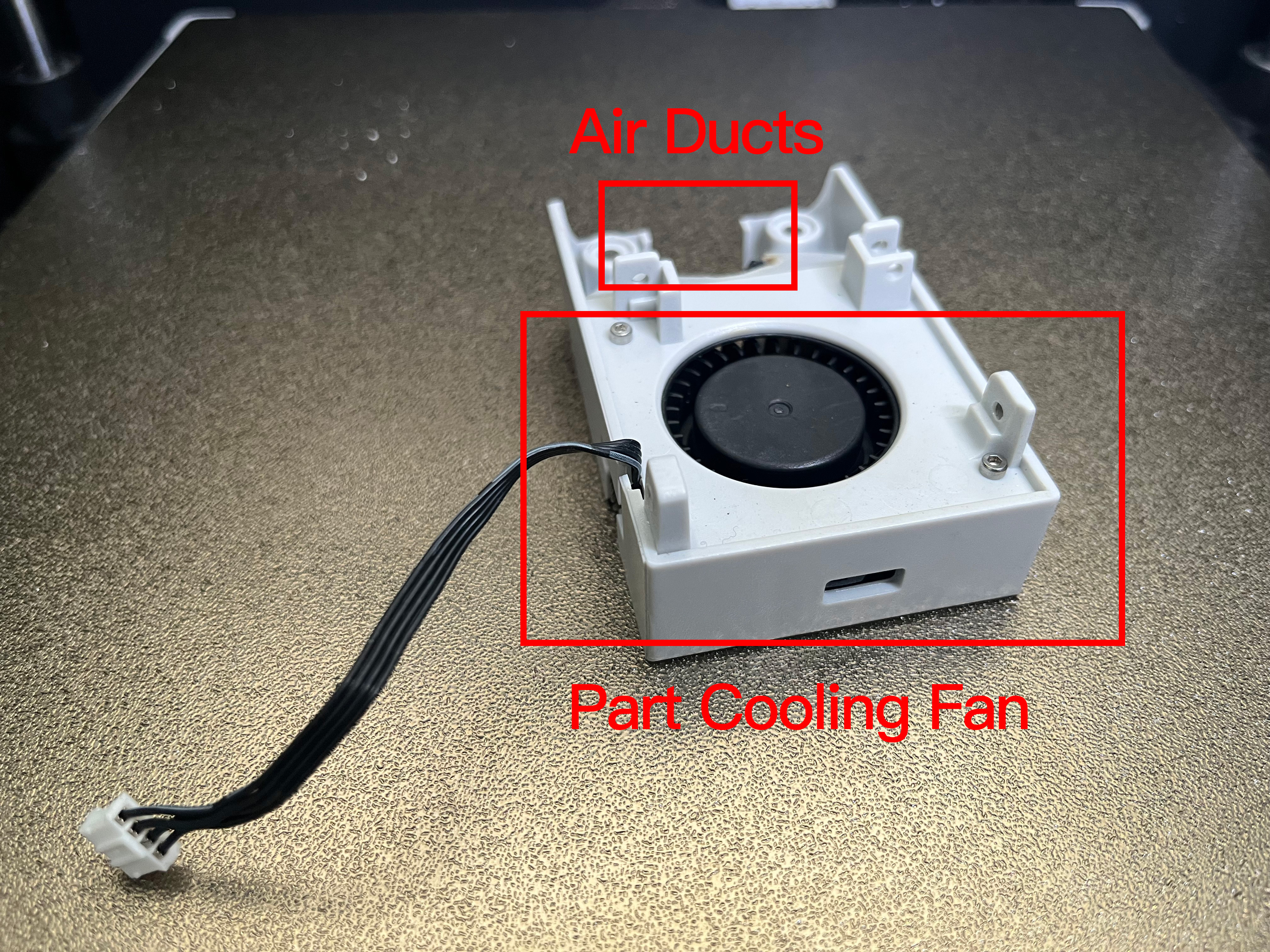

¶ Cooling System

Fast printing requires effective cooling of printed parts. The Q2 is equipped with a 5015 radial fan and dual air ducts to control airflow beneath the nozzle.

In addition, the Q2 features an auxiliary cooling fan on the right side of the printer. For certain filaments, such as PLA, enhanced cooling helps improve print quality. When enabled, the fan creates a controlled airflow around the printed part, allowing each layer to solidify more quickly.