¶ Power Loss Recovery

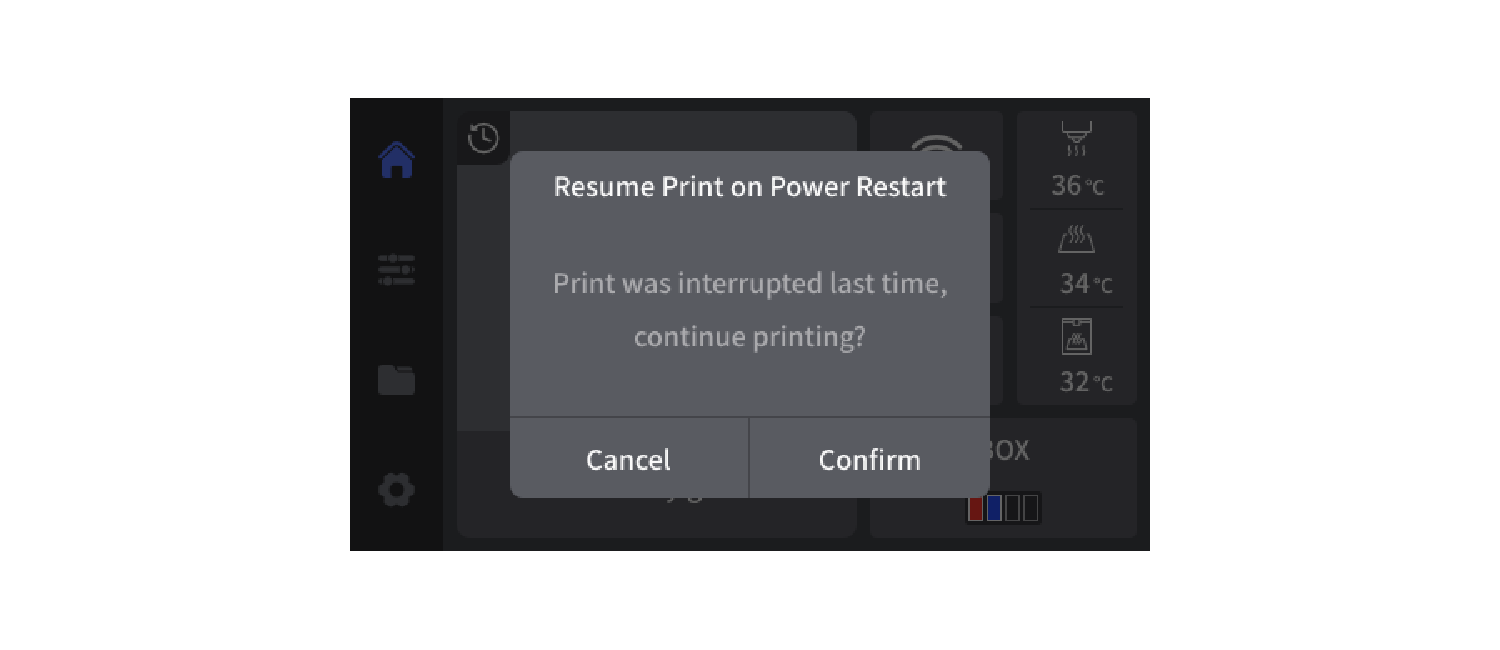

After a power outage, restarting the printer will display a recovery prompt. Tap Confirm to resume printing from the point where the interruption occurred.

Warning:

The default pause time limit is 72 hours. If this time is exceeded, the printer will not be able to resume printing.

Modify the pause time limit

¶ What Is Power Loss Recovery?

Power Loss Recovery is a feature in QIDI 3D printers that allows a print job to resume after an unexpected power interruption.

When a power loss is detected, the printer stores critical print state information, including the current toolhead position, temperatures, and progress within the G-code file. Once power is restored, the printer can reconstruct this state and continue the print in a controlled and safe manner.

This feature is designed to prevent the loss of long-duration print jobs, reducing wasted material and time.

¶ Expectations and Limitations

Power Loss Recovery cannot guarantee a perfectly seamless continuation. In most cases, a small visual mark or texture change will be visible at the recovery layer.

- For functional parts, this is usually negligible.

- For decorative or high-detail models, the mark may be noticeable.

Due to material behavior and thermal effects, Power Loss Recovery should be considered a print salvage feature, not a guarantee of flawless results.

¶ Power Loss Recovery Workflow

When the printer is powered on, it checks for a valid recovery file. If one is found, the user is prompted to resume the interrupted print.

After confirmation, the printer performs a controlled recovery sequence rather than a full startup:

- X and Y axes are rehomed, as they move to positions clear of the printed object.

- Z-axis rehoming is not performed. Instead, the printer relies on the previously stored Z position to avoid contact with the model.

- The hot end and build plate are reheated to their previous temperatures.

- A brief priming process is performed.

- The toolhead moves to the last recorded position and resumes printing from the stored G-code location.

This process requires precise mechanical alignment and stable Z-axis motion.

¶ Filament Behavior and Thermal Stability

The success of Power Loss Recovery depends heavily on the filament type and the duration of the power outage.

- PETG and TPU tolerate pauses well due to slower shrinkage and better surface adhesion.

- PLA cools quickly and may detach from the build plate once temperatures drop.

- ABS and PC are highly sensitive to temperature changes and may warp or develop internal stress after even short interruptions.

QIDI printers with enclosed chambers help reduce these risks by maintaining a more stable thermal environment.

¶ Potential Issues

¶ Warping

If the build plate cools completely during a long power outage, adhesion characteristics may change after reheating. Materials such as ABS are especially prone to warping if the chamber or build plate temperature drops.

¶ Model Detachment

As the print cools without power, the model may partially or fully detach from the build plate. PLA is particularly susceptible to this issue, especially during long pauses.

¶ Small Blob

When a power loss occurs, extrusion stops immediately, often leaving a small blob or ooze mark on the print surface. When printing resumes, the nozzle may collide with this blob, potentially causing layer shifts or model detachment.

¶ Visible Layer Line

A visible line at the recovery layer is normal. This occurs due to uneven cooling and shrinkage during the pause. Materials such as ABS and ASA are more prone to this effect, and longer outages tend to make the line more noticeable.