There are several common problems that cause the build bed to keep hitting the nozzle.

1. Please make sure you place the removable build plate on the build bed, many customers forget to place the build plate back on the bed after printing. We need to place the removable build plate on the magnetic sheet before any operation. The leveling sensor only detects the metal material. Also, without the build plate, there are four screws on the magnetic sheet, it's not a good place to print anything and do the bed leveling.

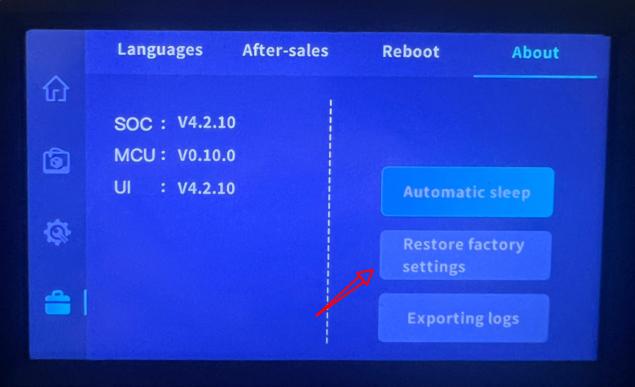

2. If you did adjust the Z-offset or calibration via fluidd page, it would mess up the Z-offset value in the printer system. The priner only able to adjust the Z-offset or calibrate anything on the printer screen, because we save the Z-offset value in different folder than the original Klipper. If you did calibrate the Z-offset via fluidd page, in that case, please click the restore factory setting on the screen and restart the printer, it will reset the Z-offset value. See the photo below.

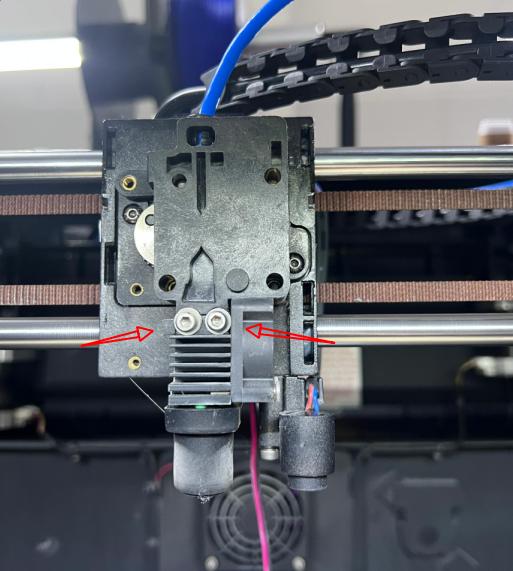

3. Hotend or nozzle is not installing in correct place. If the problem starts after you replace the hotend, please make sure you install the hotend screws correctly, many customers didn't fully insert the hotend into the extruder and caused the hotend and nozzle lower than it supposed to be. See the correct hotend installation photo below, make sure you insert the screws in the screw's hole. Also, the nozzle is custom size, if you change the nozzle length, it will cause the problem too.

For more information, please contact tech support email.