¶ X-Plus 4 printer overview

This section introduces the main components of the X-Plus 4 and explains how they work together during printing. Understanding these components will help you operate and maintain the printer more effectively.

¶ How the X-Plus 4 works

The X-Plus 4 creates 3D objects by melting plastic filament and depositing it layer by layer.

Most printable models are provided as .stl files. Before printing, these files must be processed in slicing software. The recommended slicer, QIDI Studio, converts the 3D model into thin layers and generates machine instructions (G-code).

These instructions control:

- Movement along the X, Y, and Z axes

- Filament extrusion

- Nozzle and build plate temperatures

- Printing speed

- Support structures and other settings

The printer follows these instructions to build the object layer by layer.

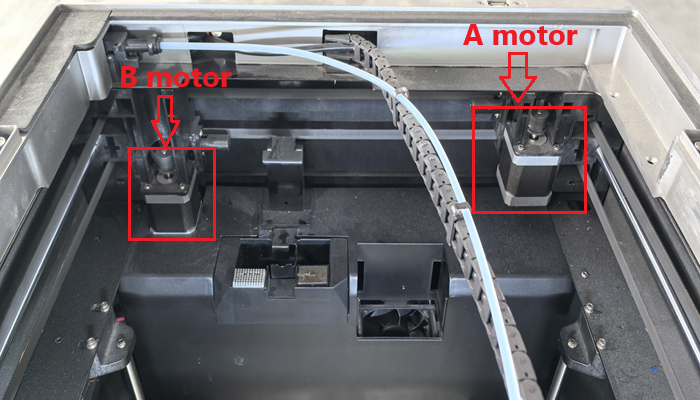

¶ CoreXY motion system

The X-Plus 4 uses a CoreXY motion system driven by two stepper motors. These motors work together to move the printhead in the X and Y directions.

Each motor drives an independent belt connected to the printhead. This design reduces moving mass and allows faster, more precise motion compared to traditional Cartesian systems.

For more information about CoreXY mechanics:

https://corexy.com/theory.html

¶ Z-axis system

The Z-axis controls the vertical movement of the build platform.

Two independent stepper motors drive separate lead screws on each side of the printer. This dual-drive design keeps the platform stable and aligned during printing.

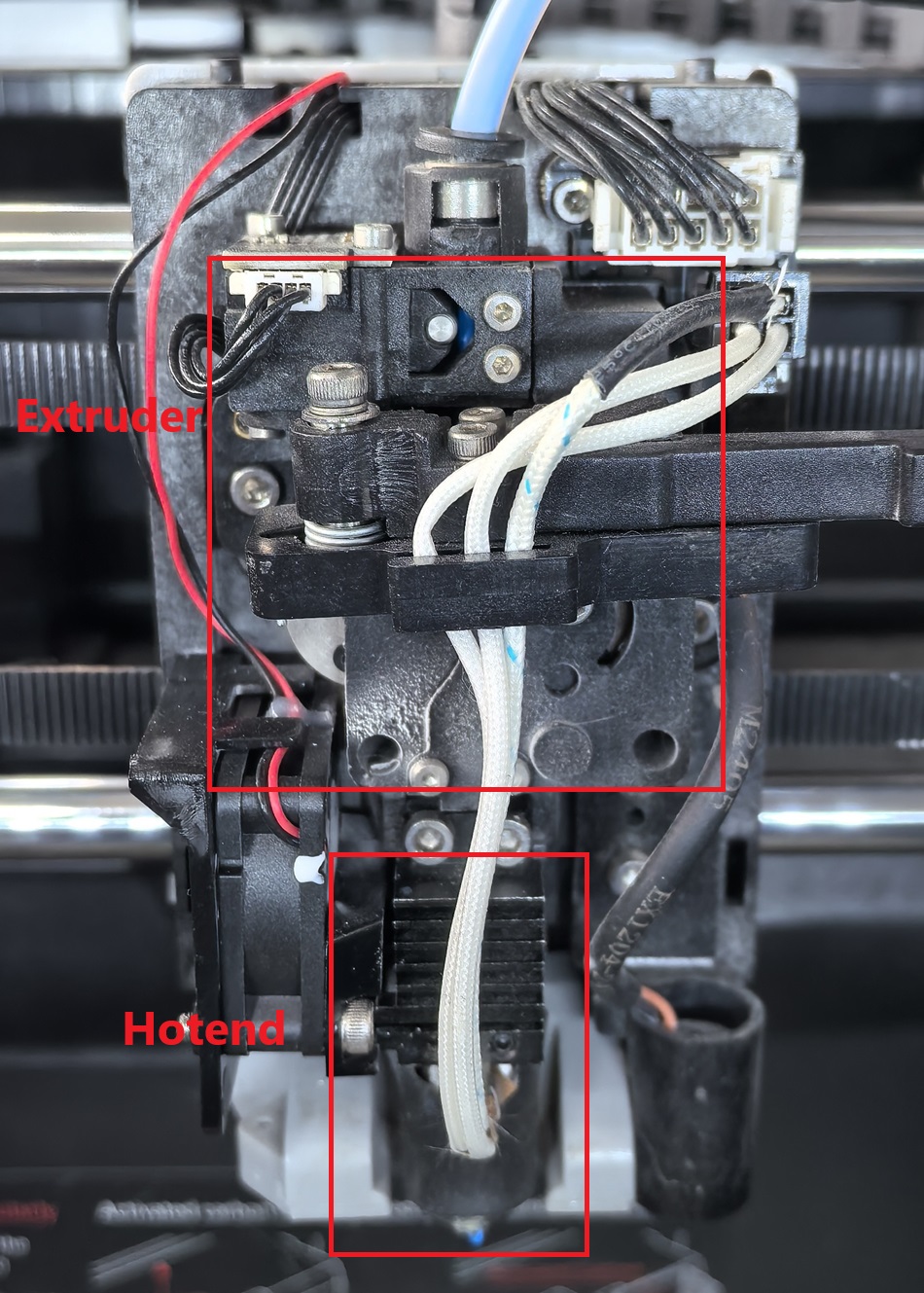

¶ Extruder

The extruder pulls filament from the spool and feeds it into the hotend. It precisely controls the amount of material delivered during printing.

Accurate extrusion is essential for consistent layer quality and dimensional accuracy.

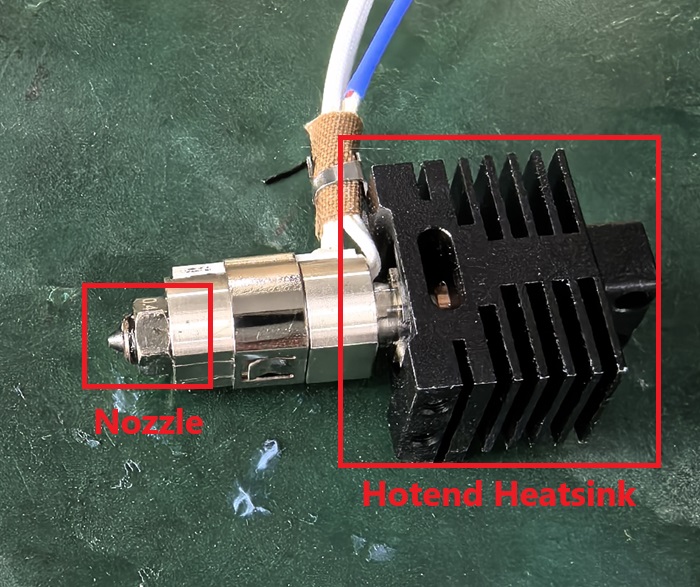

¶ Printhead and hotend

The hotend melts the filament and deposits it through a fine nozzle. Different materials require different temperatures:

- PLA: 210–220 °C

- PETG / ABS: 250–260 °C

The X-Plus 4 uses an all-in-one hotend design, where the nozzle is integrated with the heat block and connected to a heatsink through a thermal barrier.

This design improves heating efficiency and reduces maintenance complexity.

¶ Heated build plate

The heated build plate improves first-layer adhesion and reduces warping.

The build plate can reach 110 °C, depending on the material:

- PLA (cool plate): 35–45 °C

- ABS / PC: 100–110 °C

Insufficient heating can cause uneven cooling and print warping.

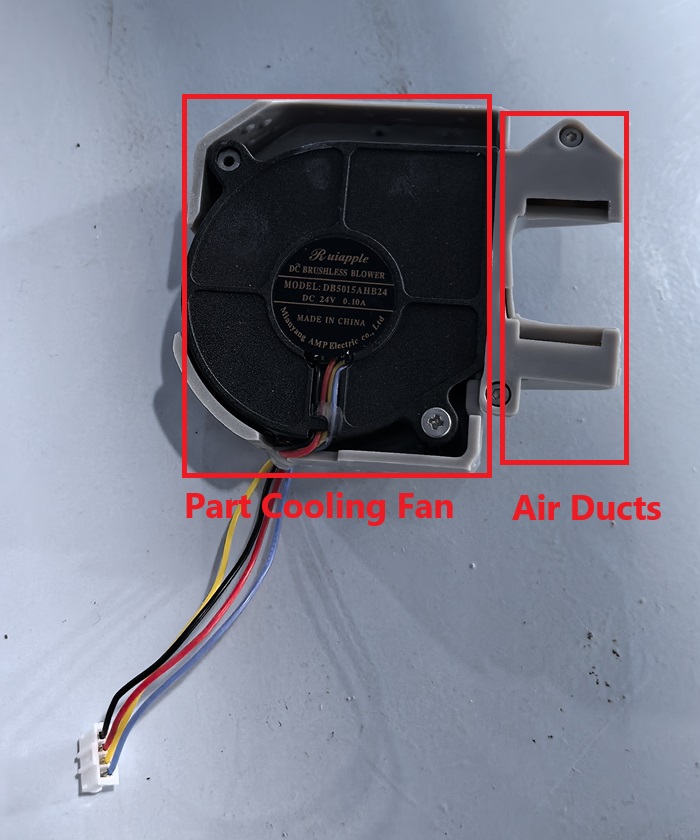

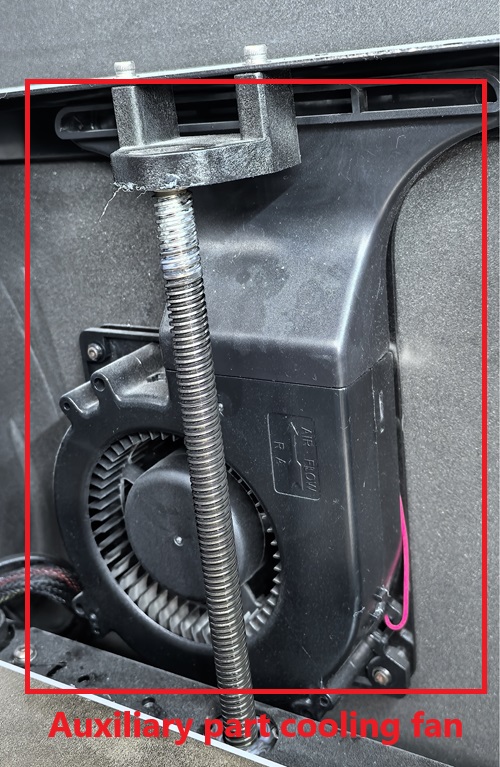

¶ Cooling system

The X-Plus 4 includes a 5015 radial cooling fan that directs airflow beneath the nozzle.

An additional side-mounted fan provides extra cooling when printing materials such as PLA.

Together, these fans help printed layers solidify quickly and improve print quality.