¶ Instructions for printing RC model with foaming ASA (ASA Aero)

ASA Aero is a kind of foaming material, which is an excellent choice for printing parts for RC (Radio Controlled) models due to its unique properties. This material is known for its reduced density, which results in lighter prints, a critical factor in the performance of RC models. In addition, compared to conventional printing materials, RC models printed with foaming ASA can avoid heavy head or tail weight, and do not require too much adjustment of the aircraft's center of gravity, making the flight of the aircraft model more reliable and safe.

However, when printing with ASA Aero, special care should be taken.The material tends to expand during printing, which requires careful calibration of the printer and precise control of the printing temperature. Furthermore, due to its lightweight nature, it may not be as durable as other materials, so it's essential to consider the part's intended use and the stresses it will endure. Lastly, post-processing techniques such as sanding or painting need to be done cautiously to avoid damaging the printed part.

¶ Unique RC Model Requirements

RC models require lightweight construction for optimal performance, but standard printing settings may not be suitable for these applications. Techniques include designing single-wall wing surfaces, avoiding retractions.

Typically, RC model planes are designed with thin walls and internal structures to enable slicers to process each layer in a single, closed-loop path. This approach allows printing to start and stop at the same position, eliminating the need for travel. QIDI Studio offers a special mode called "Sprial vase," which prints a closed loop while continuously elevating the Z-axis,further removing the start/stop points for each layer (Note: Not all models are suitable for printing in "Sprial vase" mode).

¶ Printing profile for Spiral-Vase model

Specific parameter settings:

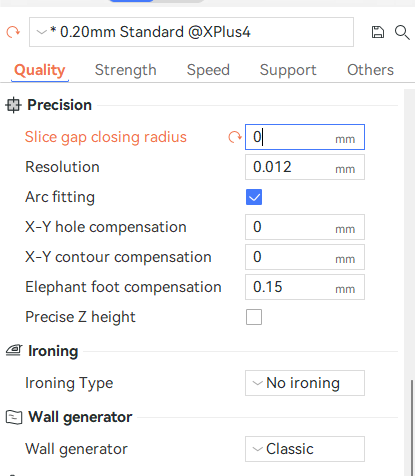

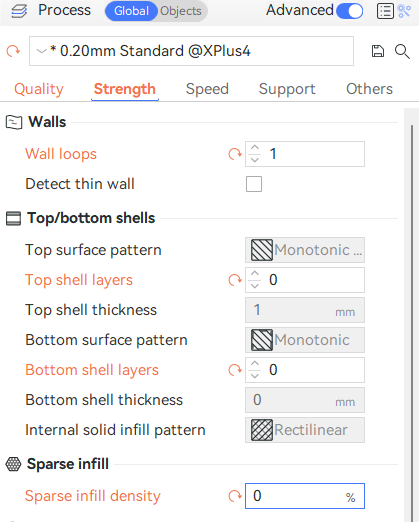

| Close the slice gap closing radius and select "Classic" in Wall Generator | Set the number of wall loops to 1;

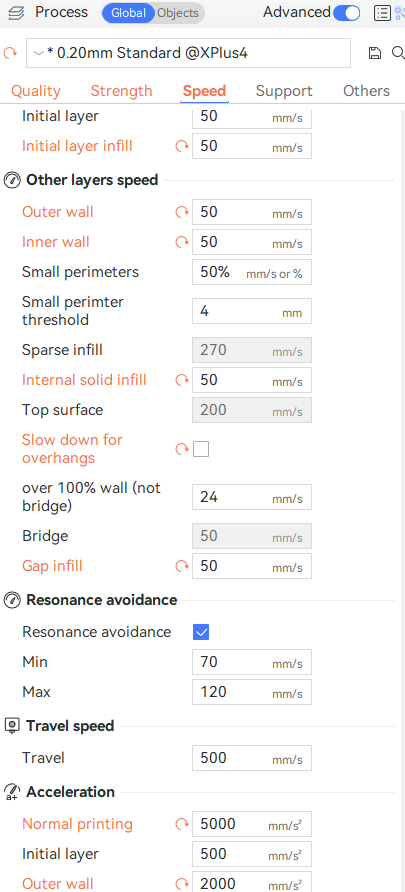

Set the number of top/bottom shell layers to 0; Set the sparse infill density to 0%; | Set all print speeds to the same and disable "Slowdown for Overhang";

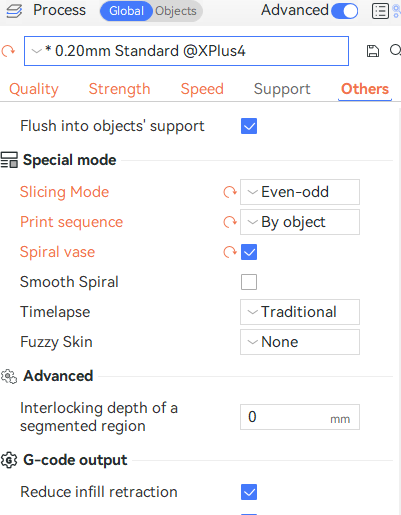

Reduce print acceleration appropriately; | Select "Even-odd" slice mode;

Enable the "Spiral vase"; Select the "by object" print sequence (if you need to print multiple models on one plate). |

|  |  |  |

¶ Print profile for non-Spiral vase mode

For some RC models, slicing with a single loop spiral may result in loss of detail, so it is not recommended to use the "Spiral vase" mode, but need to adjust the parameters. However, most of the parameters are the same as the configuration in Spiral vase mode, you only need to modify the following:

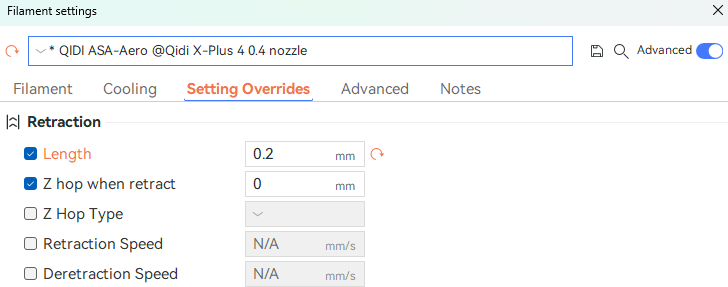

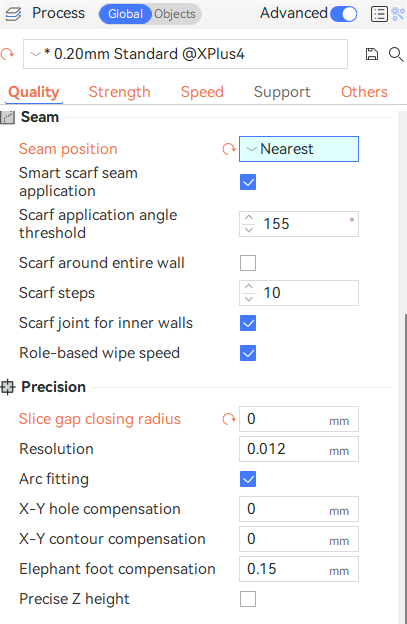

| Reduce or disable the retraction; Disable Z hop | Adjust the seam position according to the slicing result, usually select "Nearest". |

|  |

¶ Ending

Even though printing foaming ASA requires slower speeds, the X-Plus4 's accurate extrusion, input shaping, and sturdy CoreXY frame still ensure great print quality despite not using the printer's full-speed potential.

Some early RC models might not be designed to work with this special mode. You may try to slice them with the default setting and print them with normal ASA.