In the past, the 3d printer based on fdm technology will adjust the height of the nozzle after the completion of a layer of printing, and then come to the next layer of the start of the printing point, and start printing.

This way, there is a disadvantage, that is, in the printing of single wall design products need to set aside time to adjust the height and thus lead to a waste of time.

In contrast, spiral vase technology is to print a layer of dots while slightly adjusting the height of the nozzle, so that after printing all the dots of a layer, the height of the nozzle has reached the next layer, without leaving dedicated time to raise the height of the nozzle, thus increasing the speed of printing.

¶ Open

We can follow the instructions in the figure below to open spiral vase mode.

¶ Effect

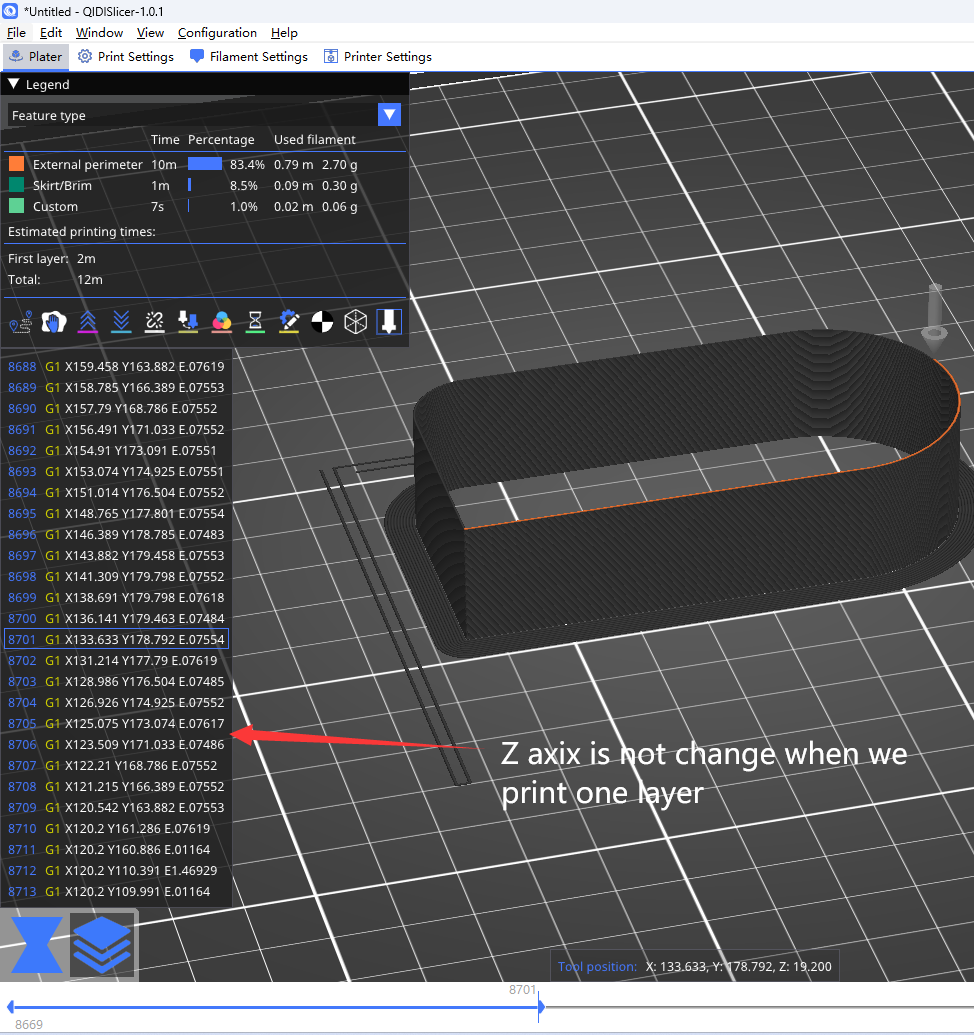

If the Spiral vase mode is not turned on, the height on the z-axis will not change when printing a layer.

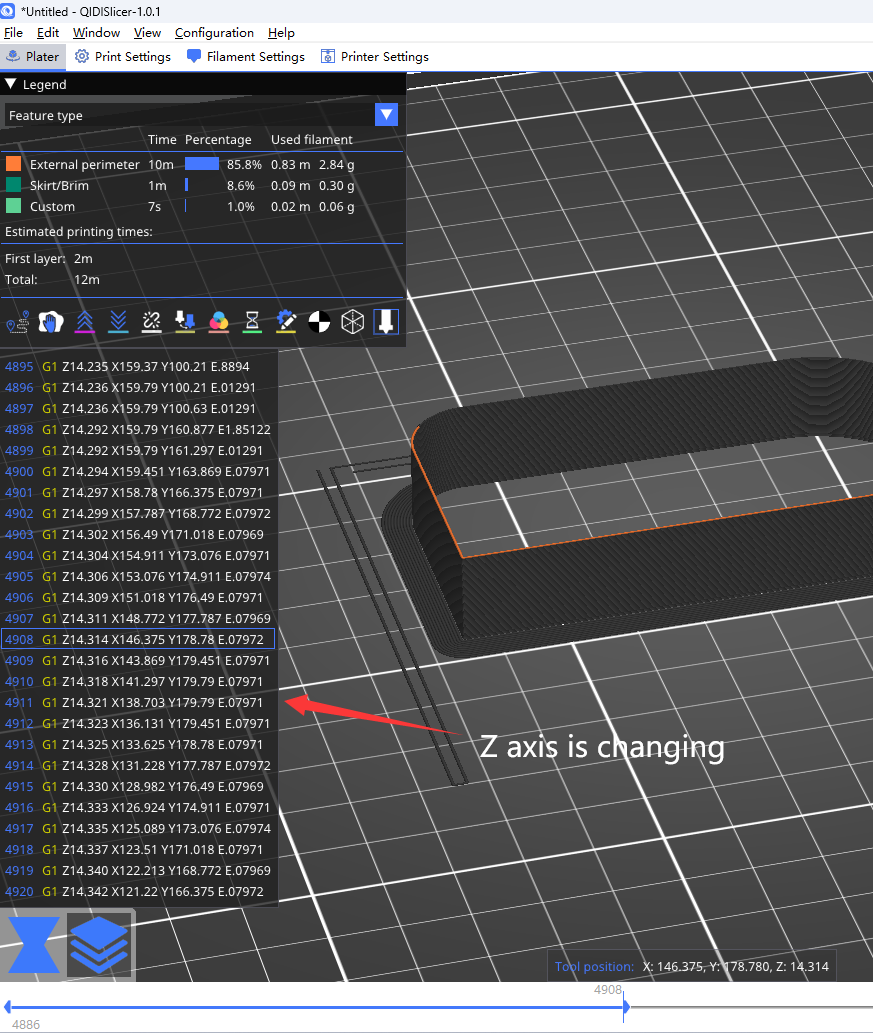

If the Spiral vase mode is turned on, the height on the z-axis will rise as you progress when printing a layer.