¶ What We May See

The problem are likely below.

¶ Background

Under-extrusion in 3D printing refers to the situation where the amount of extruded filament is insufficient during the printing process. It occurs when the extruder of the 3D printer is unable to provide an adequate amount of melted plastic to fill the space of the printed model.

There can be several causes of under-extrusion, including:

-

Low extrusion temperature: If the temperature of the extruder is set too low, the flowability of the melted plastic is affected, resulting in an insufficient extrusion. This can be due to incorrect printer settings or a malfunctioning extruder.

-

High extrusion speed: When the extrusion speed is too fast, the extruder cannot supply enough filament in a timely manner. This may be caused by incorrect printer settings or excessively high feed rates of the extruder.

-

Clogging or blockage: If there is a blockage or obstruction within the extruder or feeder system, the extrusion of plastic will be limited, leading to under-extrusion.

-

Material feeding issues: Problems with the printer's filament feeding system, such as filament jams, looseness, or inconsistent feeding, can also result in under-extrusion.

¶ Way to solve

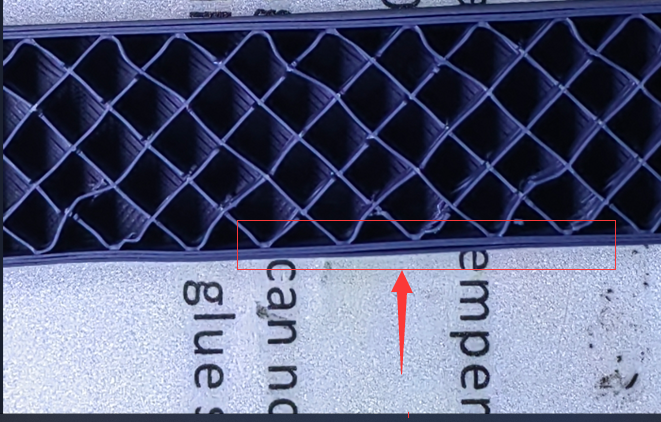

Under-extrusion typically manifests as discontinuities, hollow sections, poor interlayer adhesion, or missing details on the surface of the printed model. To address under-extrusion, you can try the following steps:

- Check and adjust the extruder temperature to ensure it is appropriate for the printing material being used.

- Adjust the extrusion speed by slowing down the feed rate of the extruder to provide sufficient filament.

- Inspect the extruder and feeder for any clogs or blockages and clear out any debris or buildup.

- Verify the material feeding system to ensure smooth and consistent filament supply without any loose or jammed components.

- Review the printer settings to ensure all parameters are properly configured.

By making these adjustments, you can improve under-extrusion issues and enhance the overall print quality.