The layer height refers to the thickness of each individual slice in the 3D printed object.

It is a crucial factor that impacts both the print time and the vertical resolution of the print.

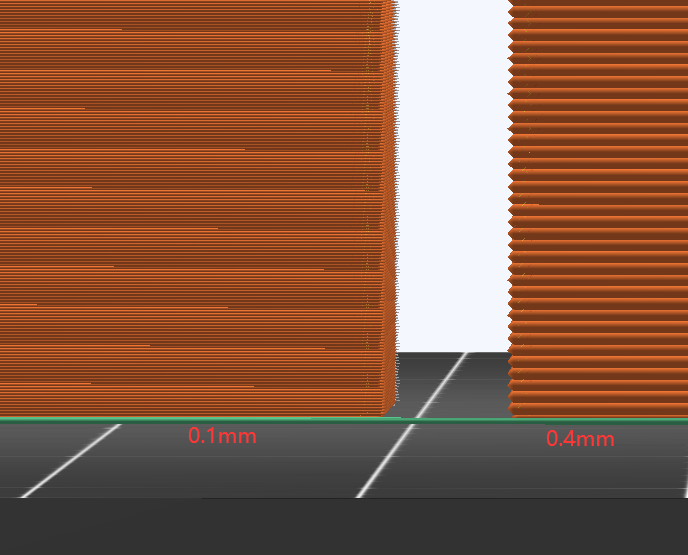

By selecting a larger layer height, you can considerably reduce the print time as each layer is thicker, requiring fewer layers to complete the object. However, this comes at the expense of visible layer lines, resulting in reduced vertical resolution and surface smoothness.

Conversely, opting for a smaller layer height, such as 0.10 mm, enhances the level of detail and improves vertical resolution. This provides a smoother surface finish and higher precision but increases the print time significantly as more layers are required to build the object.

Choosing the appropriate layer height involves finding the right balance between print time and desired resolution based on the specific requirements of the print job.

The following figure shows the effect of different layer heights on the fineness