¶ Introduction

From a fluid mechanics perspective, the flow of a Newtonian fluid through a hole necessitates pressure, which varies directly with the flow rate. Given that the filament is not rigid, upon initiating extrusion, it undergoes compression to generate pressure. This compression introduces a delay in the actual flow response, as the extruder merely supplies the necessary filament without additional material.

¶ When is a pressure advance calibration required?

- When utilizing different brands of filament or if the filament is damp.

- If nozzles are worn out or if nozzles of varying sizes are substituted.

- When employing diverse printing parameters, such as temperature and line weight.

¶ Calibration operation

We offer three pressure advance calibration modes. To access the respective mode, simply click the corresponding button at the bottom of the page:

- PA line

- PA pattern

- PA Tower

¶ PA Line

-

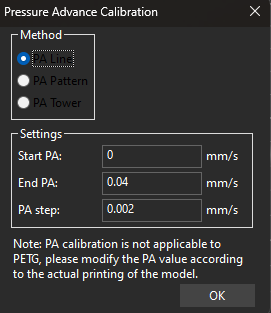

Input the initial K value, end K value, and value step in the designated boxes.

-

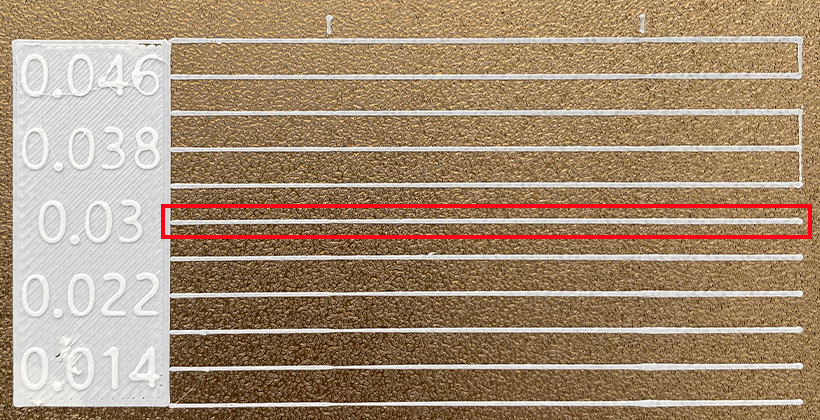

Click the OK button at the page's bottom. The software will automatically create and slice the model. Send the sliced file to the printer for printing. The printed model appears below.

-

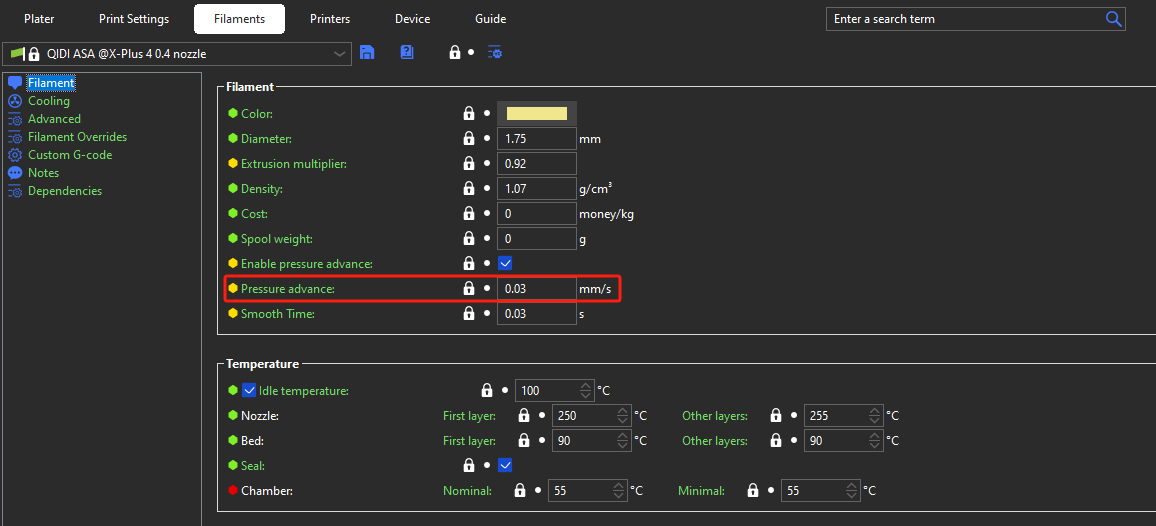

The line labeled 0.03 in the image above appears the smoothest. Enter this value into the software for saving.

¶ PA Pattern

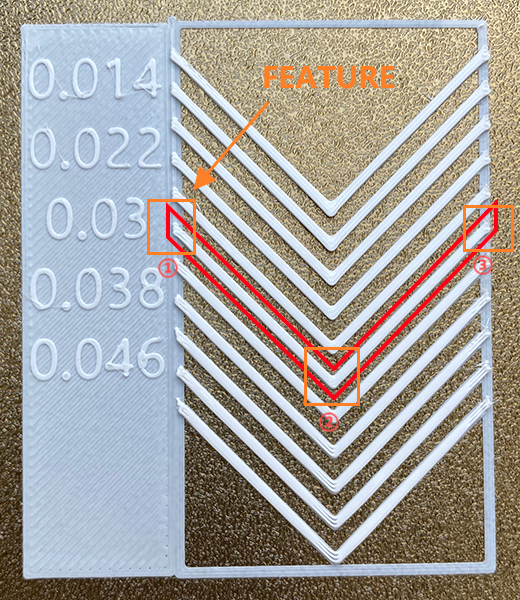

Follow the same steps as for the PA Line. The printed model is shown below.

Examine the following three areas in the model:

-

In zones 1 and 3, if the pressure advance value is too low, material accumulation occurs, causing endpoints to exceed the bounding box. Conversely, too high a value may result in segment shortages and breakpoints failing to reach the bounding box.

-

In area 2, a low pressure advance value leads to material accumulation, potentially causing excessive corner overflow during printing. A high value may result in thread loss, rounding corners, and missing lines.

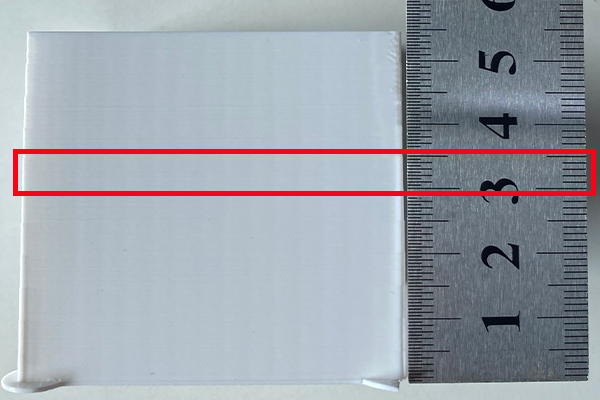

¶ PA Tower

Consistent with the above methods, but more cumbersome. A ruler is required.

Observe and align each corner of the model for calibration. The pressure advance increases in step increments for every 5 mm increase in height. If the value is too low, excessive corner squeezing occurs. If too high, right angles may round or threads may be missing at corners.

After identifying the optimal position, measure the height with a ruler and determine it using proportions.

Calculate the best pressure lead value using the formula:

Pressure advance = k_Start + floor(height/5) * k_Step

floor means round down.

Finally, the calculated value can be saved.

Note: Pressure pre-calibration is unavailable for PETG filament.