¶ Introduction

The Extrusion multiplier relates the flow rate of the nozzle. When the user uses the official filament, printing with the software's default configuration parameters performs well in the vast majority of print cases. These default configuration parameters were summarized by the experimenter through many print adjustments.

¶ When do I need calibration?

If the user experiences the following signs and other reasons for uncertainty during the printing process, a Extrusion multiplier calibration may be considered.

-

Oversqueeze.

The printed model has excess material, spots, or layers that look too thick, which can be caused by over-extrusion. -

Insufficient extrusion

The model will show signs of missing layers, gaps in the surface, or inadequate filling. This is caused by the printer not extruding enough filaments during the printing process. -

Poor surface quality

When the printed model looks rough and uneven, it may be due to incorrect flow rates. -

Weak structural integrity

The printed model is prone to breaking or not looking strong enough, which can be due to insufficient extrusion or poor layer adhesion. -

When using third party filaments

¶ Calibration process

Calibration consists of the following two processes: Coarse calibration and Fine calibration.

Generally, you can use coarse calibration first to get a rough range, and then fine-calibrate to get an exact value. If you feel that the process is too cumbersome, you can also print directly using the value obtained by coarse calibration, and you can also get a good print result.

¶ Coarse calibration

The calibration process is very simple, all you need to do is find calibration in the system toolbar and click on Flow rate - Coarse. The tool software will take care of loading the model, modifying the configuration, etc. for you. All you need to do is send the slice file to a printer and print it.

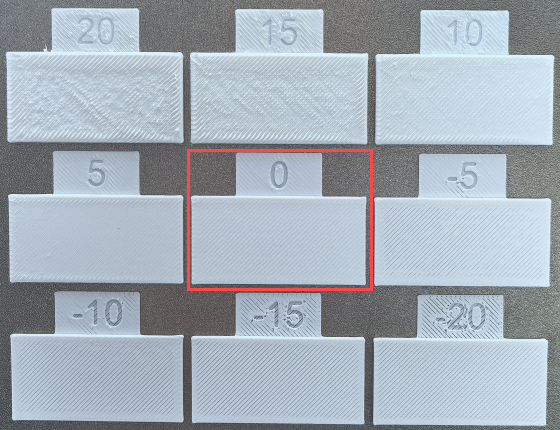

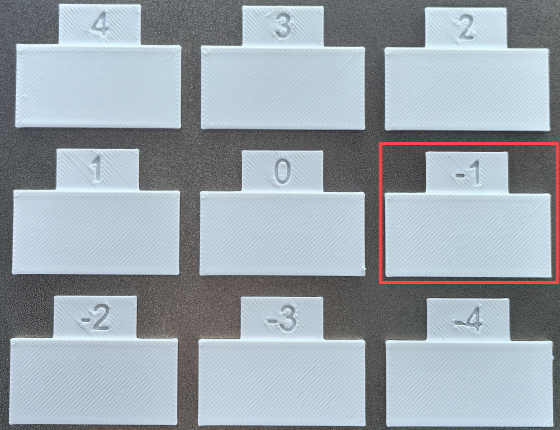

After printing successfully, you will have a model as shown in the image below, select the number with the smoothest surface. As you can see, the model with the number 0 has the smoothest surface.

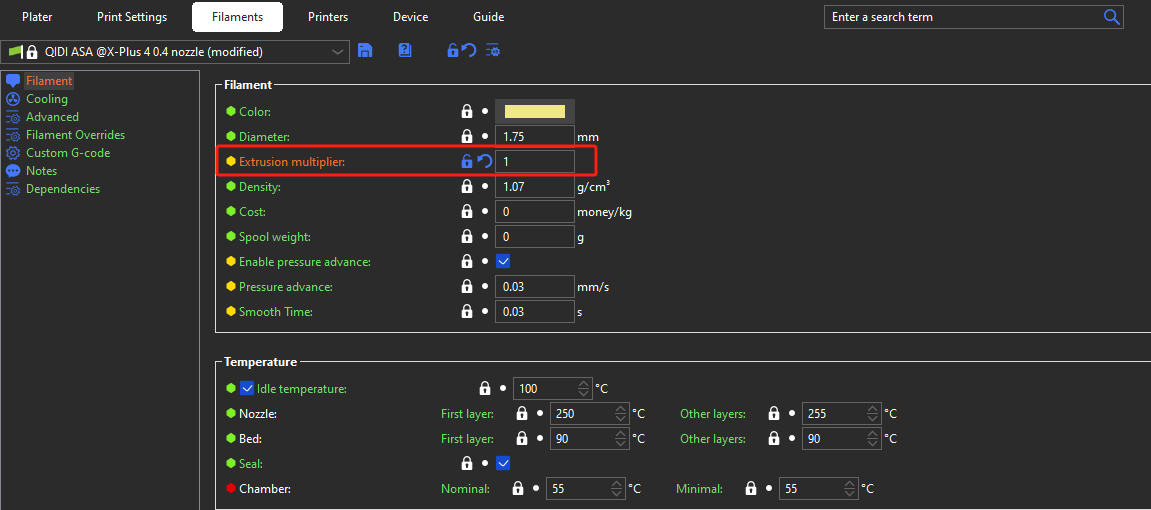

Then find the Filaments--Filament--Extrusion multiplier and calculate it with the number on the model based on its displayed parameters. As shown in the figure below, the original parameter is 1, and the smoothest number on the model surface in the printed result is 0. According to the formula: 1 + (0.00/100) = 1. That is, the original parameters remain unchanged.

If the model with the smoothest surface is 5, then calculate according to the formula: 1+(5/100) = 1.05, and modify the parameter to 1.05.

Note: The specific formula for calculating the Extrusion multiplier: 1 + (value/100).

¶ Fine calibration

Fine calibration is based on coarse calibration.

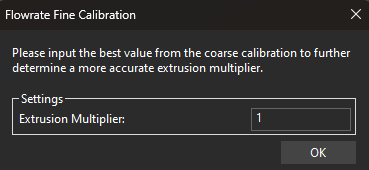

Click Calibration--Flow Rate--Fine, enter the corresponding value in the pop-up window, and click OK.

The calibration model is automatically loaded, sliced and printed. If the subsequent operations of coarse calibration are consistent, the model with the smoothest surface is selected, as shown in the figure below, and the model with the smoothest surface is -1, then the final result is 0.99 according to the formula: Input value + (-1/100).

Enter 0.99 into Filaments--Filament--Extrusion multiplier to verify.