¶ Introduction

Once melted plastic exits the nozzle, it is no longer under the precise control of the extrusion system. Two key challenges arise:

- Printing must occur on an already solidified layer. Otherwise, the previously extruded plastic may shift or distort when the new layer is added.

- Overhangs and bridges require immediate solidification. Without rapid cooling, the filament will sag under its own weight.

QIDISlicer is designed to optimize cooling settings for various filament types, significantly enhancing cooling performance.

¶ Cooling

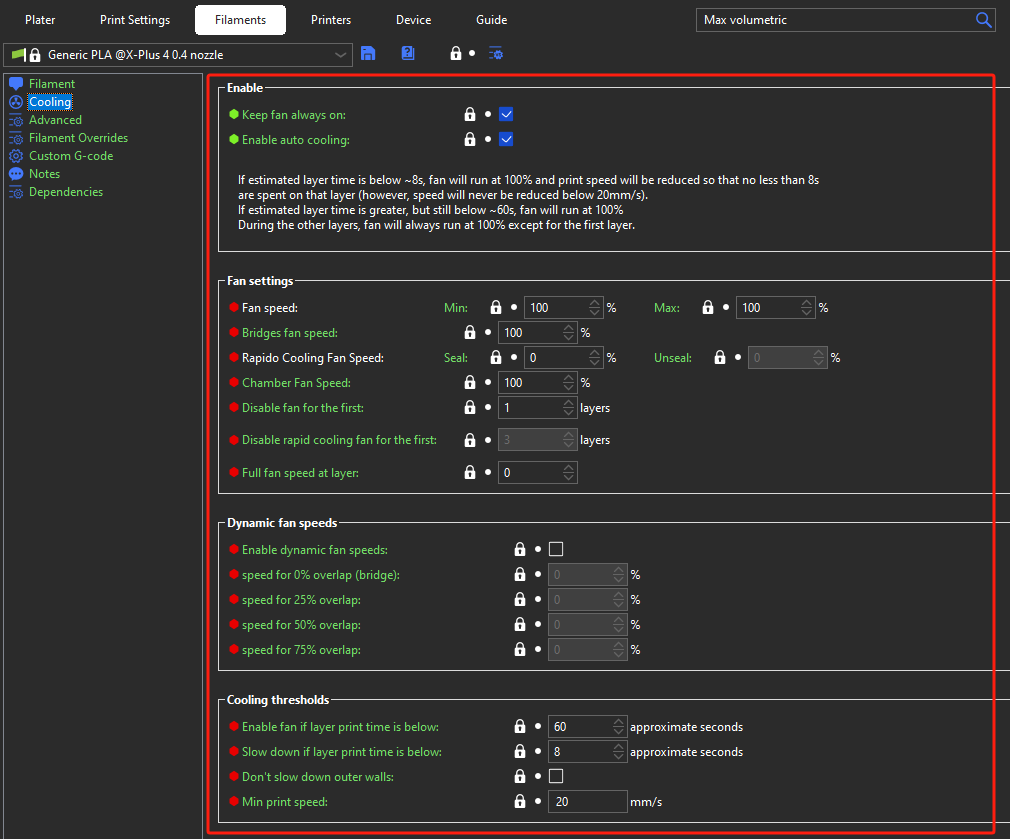

You can find Cooling settings in Filaments -> Cooling.

¶ Keep fan always on

This setting ensures the print fan maintains a minimum speed throughout the print. It is generally enabled for most materials, except for ABS, ASA, PC, and some flexible filaments.

¶ Enable auto cooling

When activated, the cooling fan speed and print speed adjust dynamically during the print based on the configured settings. A live text description below the settings provides detailed feedback on how changes affect cooling behavior.

If disabled, the fan operates at a fixed speed (set by Fan speed - Min) except during bridges, where the speed is defined by Bridges fan speed.

¶ Fan settings

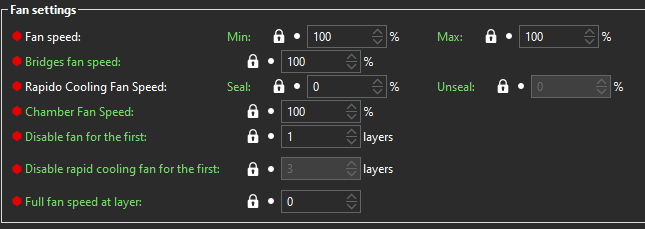

¶ Fan speed

You can set Min and Max fan speeds as percentages of the fan's maximum RPM.

-

Max speed applies when the layer print time is below the value set for Slow down if layer print time is below.

-

Min speed applies when the layer print time exceeds the value set for Enable fan if layer print time is below.

For layer print times between these values, the fan speed adjusts proportionally between the Min and Max settings.

If this seems complex, refer to the live-updating text description above the Fan settings. Adjust the values to see how the description updates.

¶ Bridges fan speed

This setting overrides the fan speed specifically for printing bridges and overhangs. Higher speeds are typically recommended for these scenarios compared to standard printing.

¶ Disable fan for the first X layers

Cooling is generally unnecessary for the very first layer since it is laid on a flat surface. For many filaments, disabling cooling for the first 1-5 layers can help prevent warping and detachment from the print bed, which could ruin the print.

¶ Dynamic fan speeds

Dynamic fan speed adjusts based on the overlap percentage between the current and previous layers:

-

100% overlap represents no overhang.

-

0% overlap represents a complete overhang (e.g., bridges).

Fan speeds for intermediate overlap percentages are calculated using linear interpolation. Input values are defined as percentages of the fan's maximum RPM.

¶ Cooling thresholds

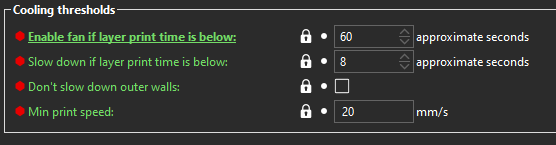

¶ Enable fan if layer print time is below

When the estimated layer print time falls below this threshold (in seconds), the fan is activated. Its speed is interpolated between the Min and Max settings.

¶ Slow down if layer print time is below

If the estimated layer print time is below this value, the printer slows the print speed to extend the duration to this threshold. This adjustment scales all print speeds proportionally, so some movements may still be faster than others.

¶ Min print speed

This setting determines the lowest allowable print speed during slowdowns. Extremely low speeds for extended periods can cause issues like heat creep.

However, setting this value too high might override the Slow down if layer print time is below threshold. Even at the minimum speed, the layer time might fall short of the desired duration.