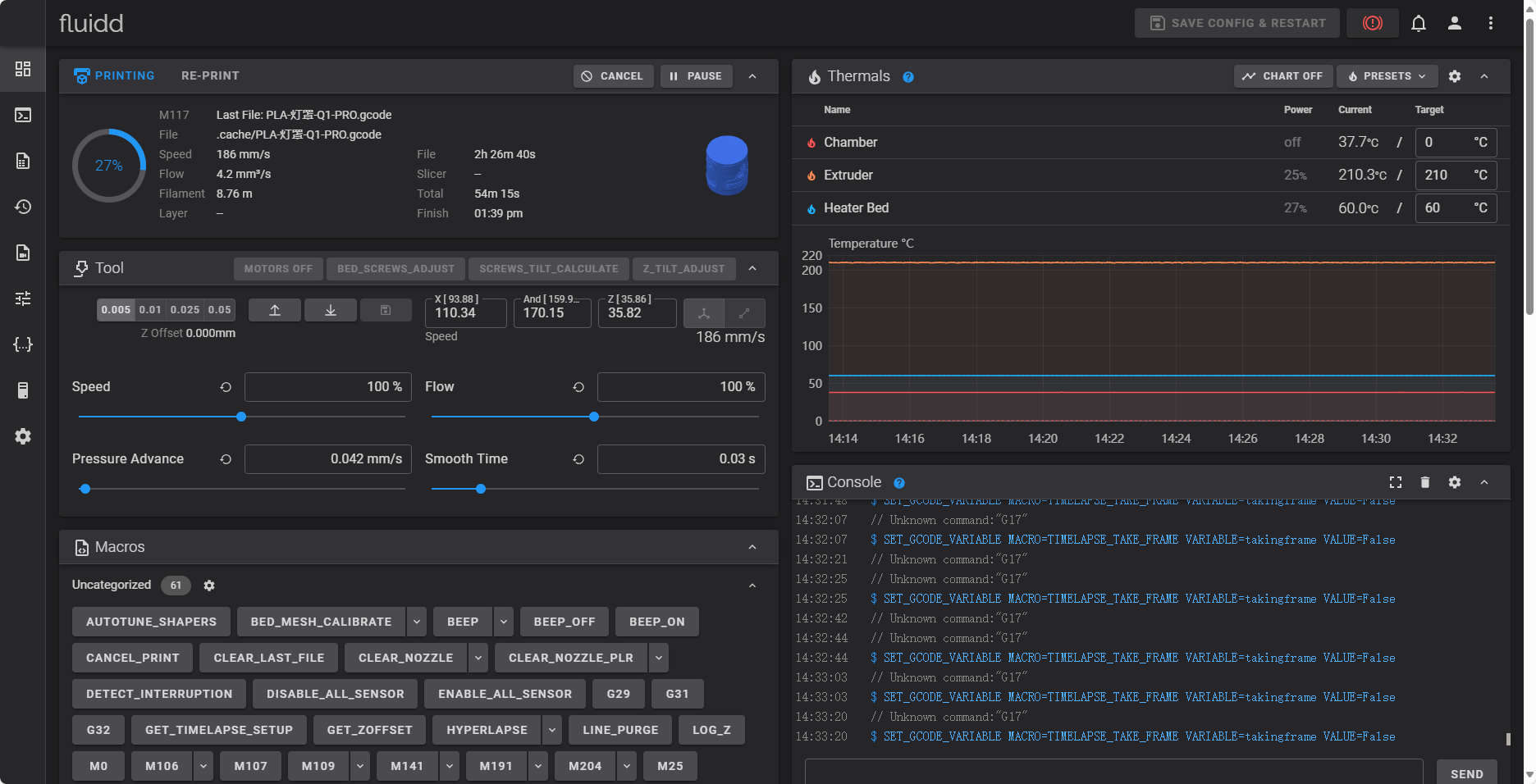

The Fluidd page is displayed on the right of the device page.

Fluidd is a powerful operating system that can control and monitor the operation of 3D printers.

Through its Web-based user interface, users can control the printer's print head movement, monitor the real-time status of the printer, print progress, temperature parameters, and more. Set print parameters to start or stop the current print. This helps to easily manage and optimize the printing process, thereby improving production efficiency and print quality.

¶ Home

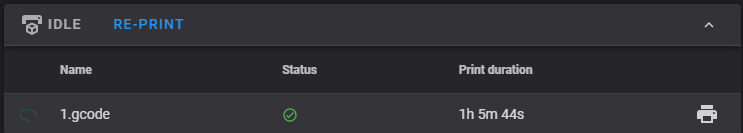

¶ Ready

In the Ready module, you can view information such as status, print time, and so on for several recently printed models.

You can print the model again by operating the mouse.

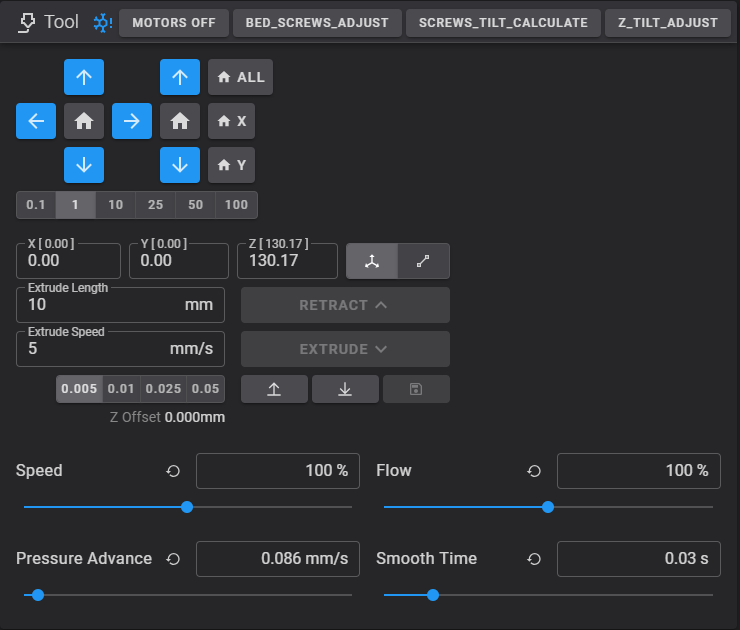

¶ Tool

You can move and set the printer nozzle through this module.

The printer nozzle can be moved by mouse command, or the moving speed and extrusion amount of the nozzle can be set. The printer can also be levelled with the built-in button.

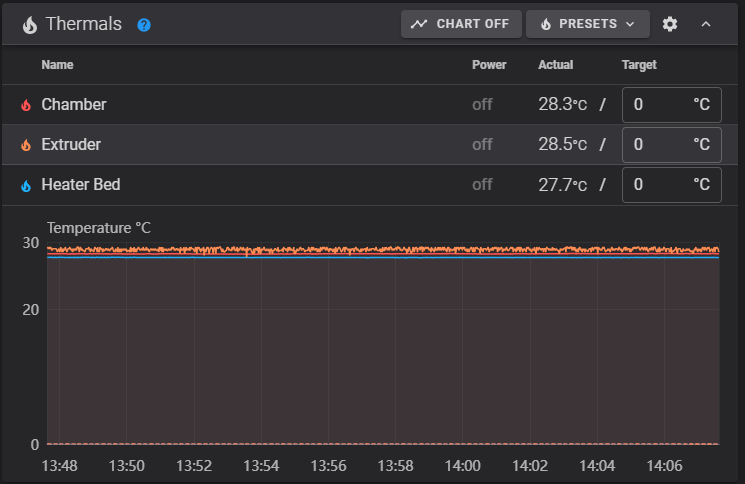

¶ Temperature

You can check the temperature of the printer in real time by viewing the module, including: extruder (nozzle), chamber, printing board, etc.

You can edit the target temperature value of each module, and you can also clearly understand the temperature change of each component during the printing process by viewing the chart.

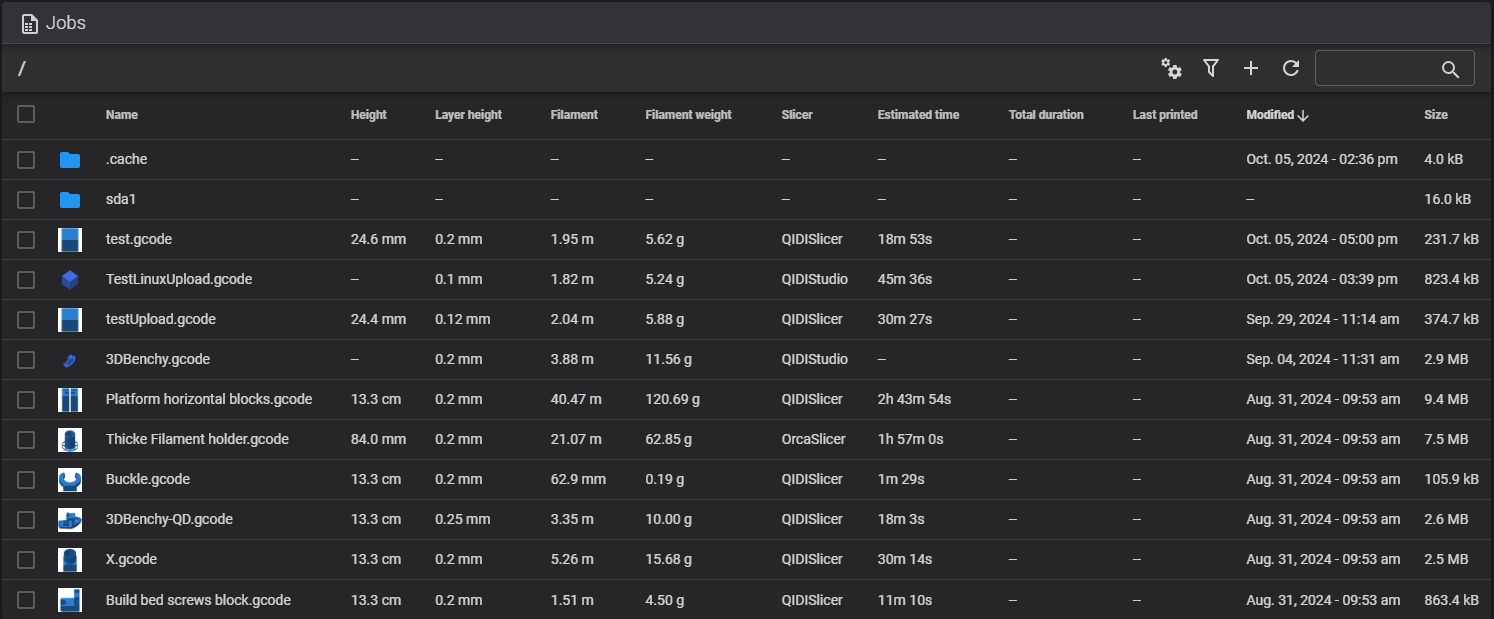

¶ Jobs

The jobs list shows all the model files saved locally on the device. The user can view the details of the task through the task list: the height, the amount of consumables expected to be used, the slicing software, and so on.

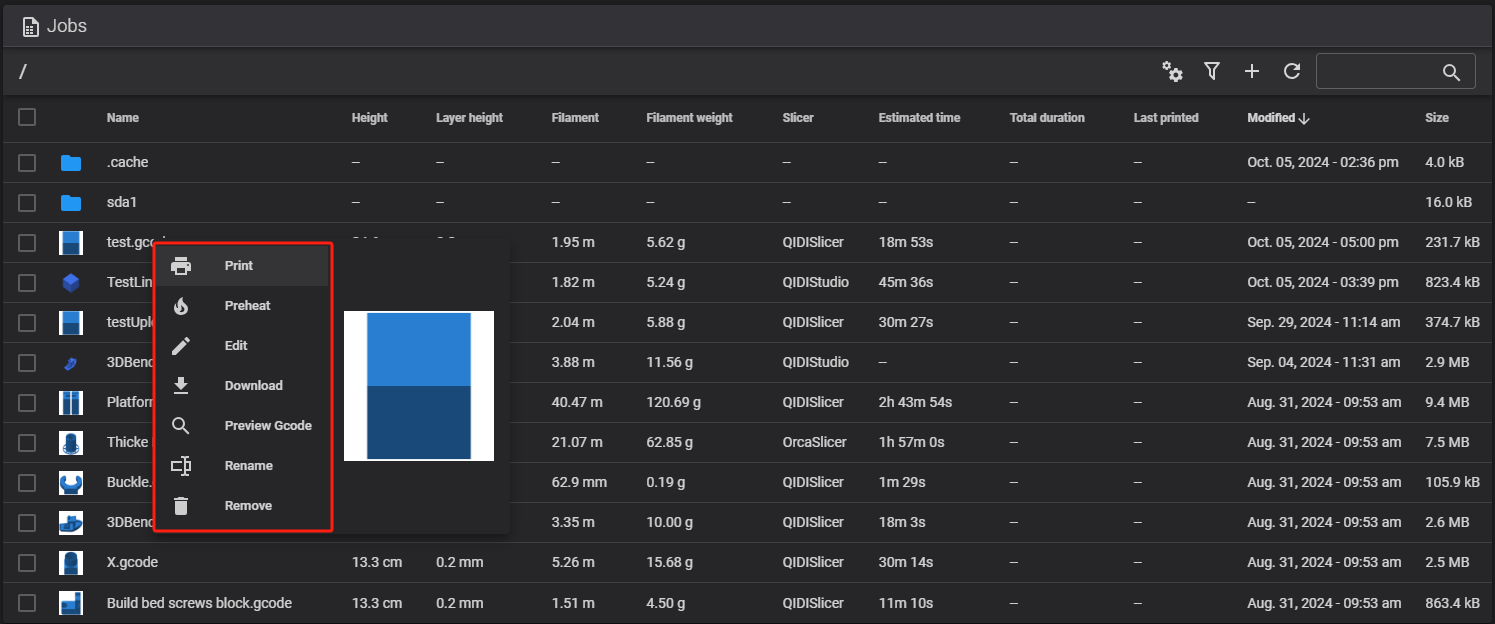

Use the mouse to click the file in the list of people, you can print, preheat, edit, download, preview Gcode, rename, delete the file.

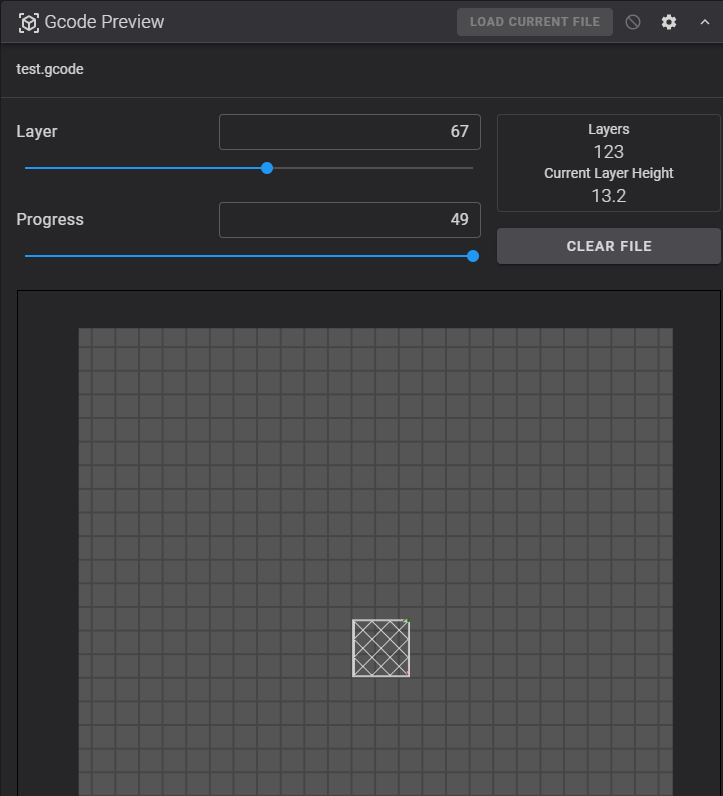

¶ Gcode Preview

-

Use your mouse to click on any model in the list of characters and select "Preview Gcode"

-

The Gcode code corresponding to the model will be read into the Gcode preview module, where you can preview the Gcode file layer by layer or line by line.

For more information about Fluidd, please refer to Fluidd Official Documentation.

** Note: If you have already started printing models, do not use fluidd to set up the printer. Otherwise, the printing effect of the model will be affected, and even the printing will fail. **