The Arachne generator produces perimeter loops and gap fills with varying extrusion width. Simply put, it automatically makes perimeters wider or thinner as needed.

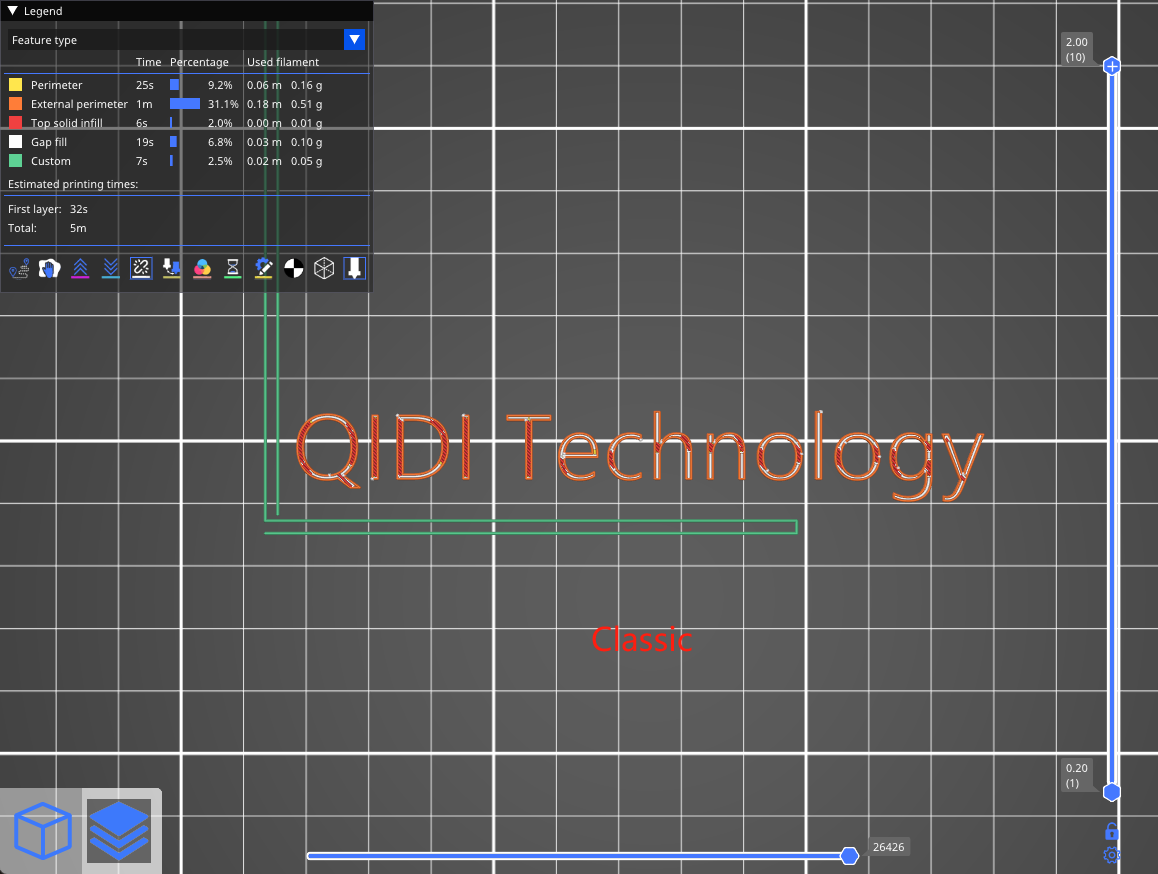

There are two contour generators available in QIDISlicer for you to choose from: Classic and Arachne. You can switch to it in the Print settings - Layer and perimeters - Perimeter generator settings.

| Classic | Arachne |

|

|

Arachne mode produces nicer-looking prints with fewer artifacts. There is a significant reduction in gap fill, small extrusions used to fill gaps between perimeters, which also results in a reduction of print time.

The Detect Thin walls feature is disabled when the Arachne perimeter generator is selected as it’s not needed since Arachne always tries to adapt the extrusion width to thin lines.

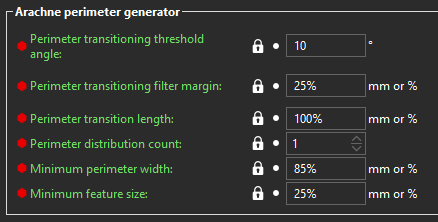

You can adjust the Arachne perimeter generator settings in:

Print settings - Advanced - Arachne perimeter generator.

-

Minimum feature size

Minimum thickness of thin features, expressed in millimeters or as a percentage of the nozzle diameter.Features thinner than this value will not be printed.Feature thicker than the minimum will be widened to the minimum perimeter width. -

Minimum perimeter width

Width of a perimeter that will replace thin features defined by the Minimum feature size. -

Perimeter transition length

When transitioning between a different number of perimeters as the part becomes thinner, a certain amount of space is allocated to split or join the perimeter segments. This value defines the length of this transition area. -

Perimeter transitioning threshold angle

An angle at which a transition between even and odd number of perimeters should happen. A wedge shape with an angle greater than this value will not have transitions and no perimeters will be printed in the center to fill the remaining space. Lowering this value reduces the number and length of these center perimeters but may leave gaps or overextrude. -

Perimeter transition filter margin

This value is used to prevent transitioning back and forth between one extra perimeter and one fewer. It is expressed in millimeters or as a percentage of the nozzle diameter.

Increasing this margin reduces the number of transitions, which reduces the number of extrusion start/stops.