¶ Introduction

Sometimes, there is a need to pause during the printing process. For instance, when adding non-printable components such as springs to the model. Upon resuming the print, these non-printable parts will be integrated or fixed within the model.

¶ Insert pause at layer

Inserting a pause at a certain height can facilitate the insertion of magnets, weights, nuts, or other objects into your prints. Once printing resumes, these inserted items will be encapsulated by subsequent layers.

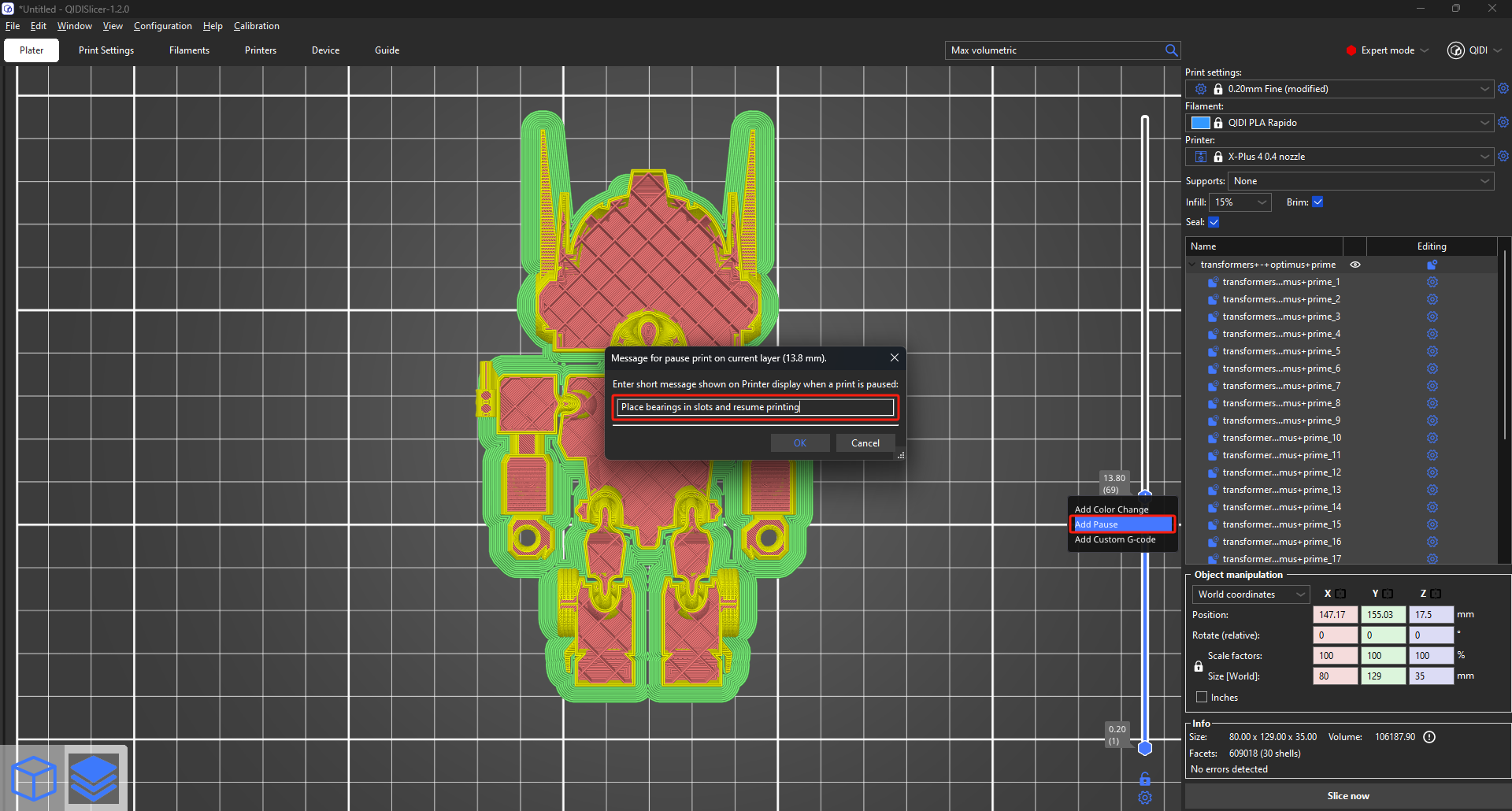

- A pause can be inserted from the Preview window.

- Drag the layer slider on the right to select the desired layer.

- Right-click on the blue plus icon

- Select "Insert Pause Print (M601)". The pause will be inserted before the selected layer begins printing.

- Add a brief message that will be displayed on the printer's LCD screen when the print is paused, such as "Place bearings in slots and resume printing".

- Confirm the Pause by hitting OK

You can remove the pause by moving the slider to the pause layer and clicking the gray cross icon.

You can edit the pause message by right-clicking on the gray cross icon.

Insert Pause and Insert Custom G-code do not function if Sequential Printing is enabled.

When slicing the print again with inserted print pauses, you will receive time estimates until each pause.

When inserting magnets, ensure they are securely placed in their slots. Otherwise, they may adhere to the print head as it passes over. Either design the slots with a tight tolerance or use a small amount of superglue to keep them in place.

¶ Insert custom G-code at layer

Inserting custom G-code can be beneficial for advanced users when creating calibration G-code, such as for a temperature tower.

You must make sure that the GCode code you enter is correct and that you know clearly what it is used for.

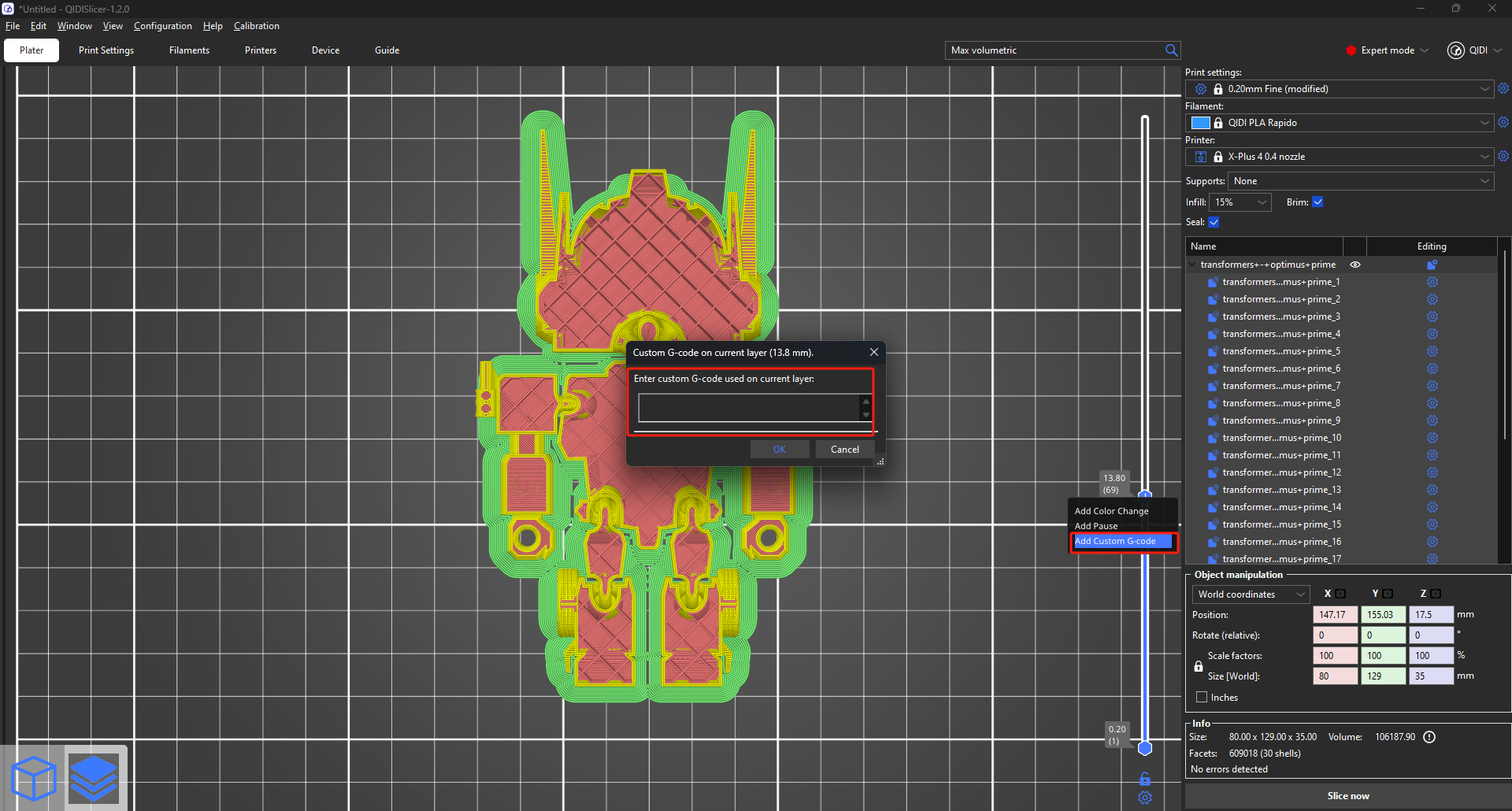

- Custom G-code can be inserted from the Preview window.

- Drag the layer slider on the right to select the target layer.

- Right-click on the blue plus icon.

- Select "Add Custom G-code". The custom G-code will be inserted before the selected layer begins printing.

- Enter the custom G-code into the newly opened window. You can add multiple commands at once by pressing Enter to insert a new line.

- Confirm by clicking "OK".

You can remove the custom G-code by moving the slider to the target layer and clicking the gray cross icon.

You can edit the custom G-code by right-clicking on the gray cross icon.

¶ Most commonly used Custom G-code commands

- M104 - Set Hotend Temperature

M104 S260 ; set the current hotend temperature to 260 degrees

You can use this command to create a temperature tower by changing the hotend temperature at various layers.

- M109 - Wait for Hotend Temperature

M109 S260 ; wait for the hotend to reach 260 degrees before proceeding

If the temperature is set with the letter S then M109 waits only when heating. If the temperature is set with the letter R then M109 will also wait for the temperature to go down.