¶ Introduction

The Maximum volumetric speed setting (MVS) is one of the most powerful features in QIDISlicer. The MVS setting essentially creates a manager for the maximum amount of filament that the slicer will attempt to push through your 3D printer’s hotend.

Instead of calculating a range of speeds for different nozzle sizes, layer heights, or extrusion widths, you can directly specify the speeds and settings you want. MVS will then regulate the speeds during slicing only when necessary.

Max volumetric speed = Layer Height × Extrusion Width × Speed

Independent MVS values can be set under both Print settings and Filament settings. In your print profile, you'll typically have an all-around default value based on your hotend hardware. In filament profiles, you can adjust MVS as needed to account for filament characteristics.

Set MVS to zero (0) for no limit.

MVS is sometimes referred to as auto-speed (auto speed).

¶ MVS in Print settings

Print settings - Speed - Max volumetric speed (Expert mode)

This value sets the overall maximum volumetric speed. Even if a higher MVS value is set in the Filament Settings, it will not exceed this value.

¶ MVS in Filament settings

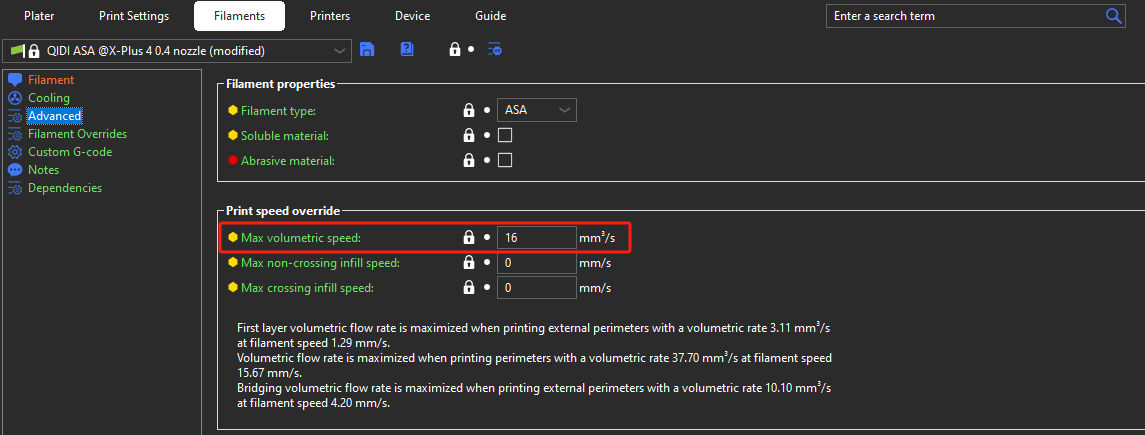

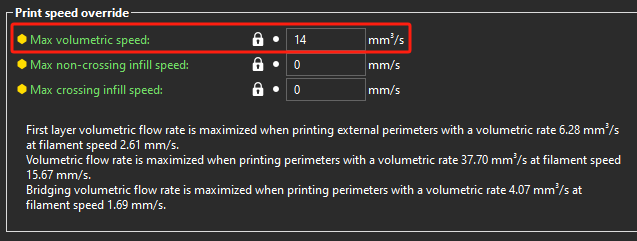

Filament settings - Advanced - Max volumetric speed (Expert mode)

This value is capped by the MVS set in the Print Settings but can be overridden to a lower value.

For small prints, neither linear speeds nor maximum volumetric speed typically matter. The nozzle rarely reaches full speed and spends most of the time accelerating and decelerating at lower speeds.

¶ Choosing MVS

¶ Filaments

Different filament materials have varying characteristics. Properties like viscosity and stiffness can significantly reduce effective throughput.

¶ Nozzle diameter

Intuitively, the nozzle diameter might seem irrelevant to the maximum amount of plastic the hotend can heat in a given time. However, with bigger nozzles, MVS can be slightly increased due to reduced mechanical resistance— essentially, it’s easier for the filament to pass through the nozzle.

Conversely, with smaller nozzles, you’ll need to reduce MVS slightly.