¶ What is bridge?

Bridge means the line that is completely extruded in the air, it is not supported by the last layer or heat bed, and the overhang degree reaches 100%.

Layer height and line width can only be controlled when extruded on an existing surface, such as a previous layer or heat bed. If it is extruded in the air, the line shape will always be circular.

Therefore, we are unable to set the layer height and line width for the bridge. The printer can only control the extrusion flow when printing the bridge. When the bridge first leaves the nozzle, it must be a cylinder with the same diameter as the nozzle. In the air, it may remain as thick as the nozzle diameter, or it may be pulled thinner. The thickest bridge that can be printed from a 0.4mm nozzle will be a 0.4mm cylindrical shape.

¶ Thick bridge and bridge flow

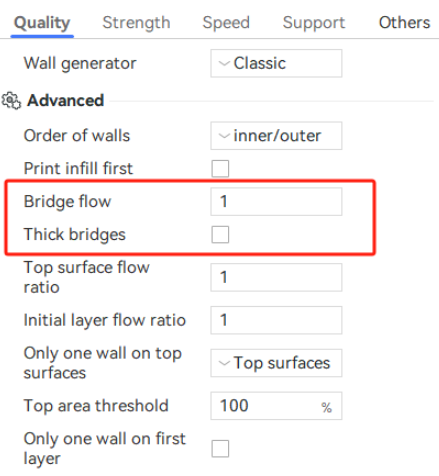

You can set the bridge flow and thick bridge in Process - Quality.

¶ Thick bridge

The thick bridge refers to the extrusion of a bridge line that is equal in diameter to the nozzle. For example, using a 0.4mm nozzle to extrude a 0.4mm diameter bridge, the bridge line is called the thick bridge. This parameter only applies to external bridges, and internal bridges within the model (such as bridges on sparse infill) always have the thick bridge enabled.

When the thick bridge is not enabled, the extrusion flow of the bridge and overhang wall is calculated according to the layer height and line width of the original line type. If the original line type is 0.2mm layer height and 0.4mm line width, when it is an overhang wall or bridge, the flow rate of the bridge is calculated according to the layer height and line width.

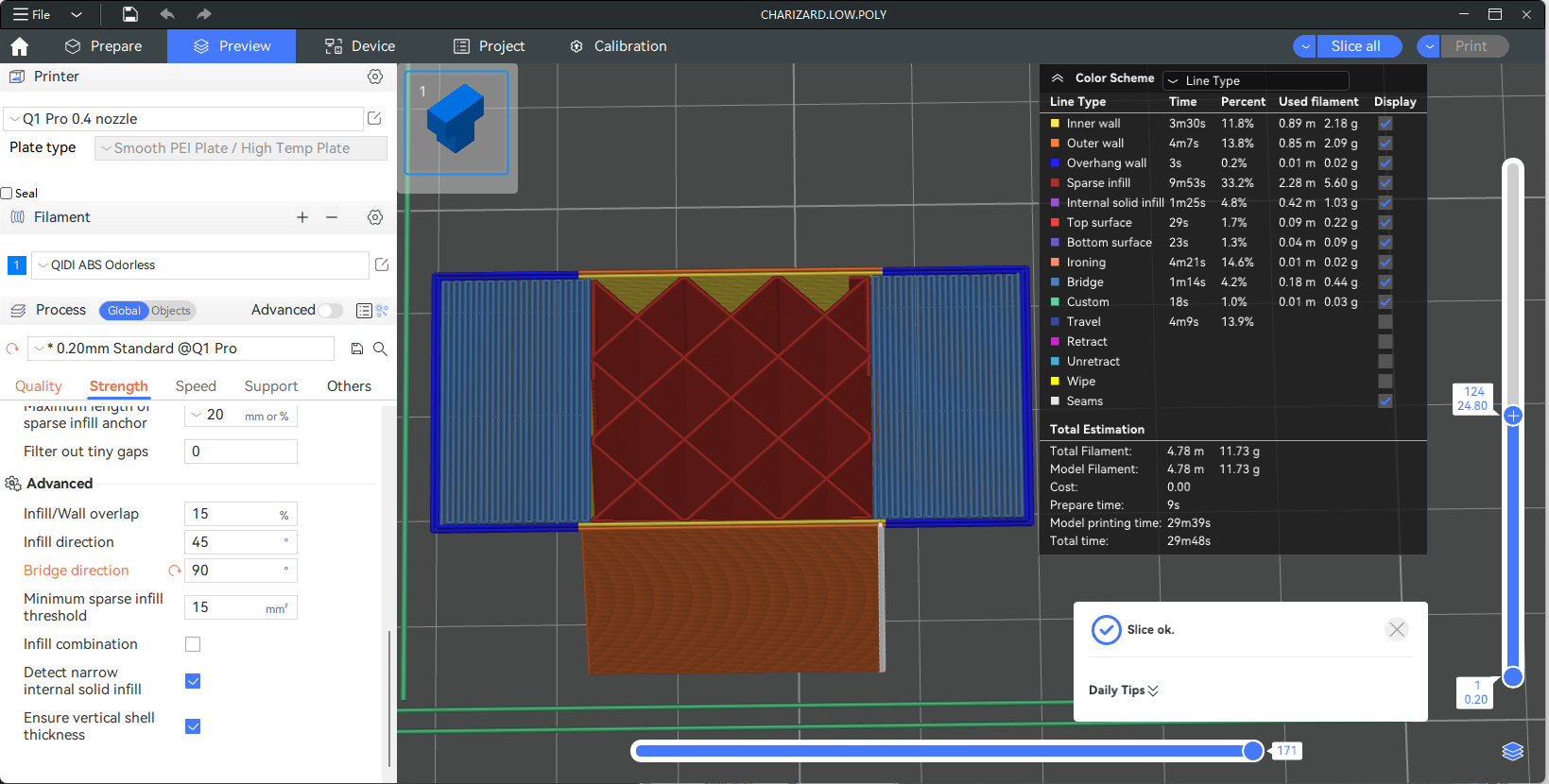

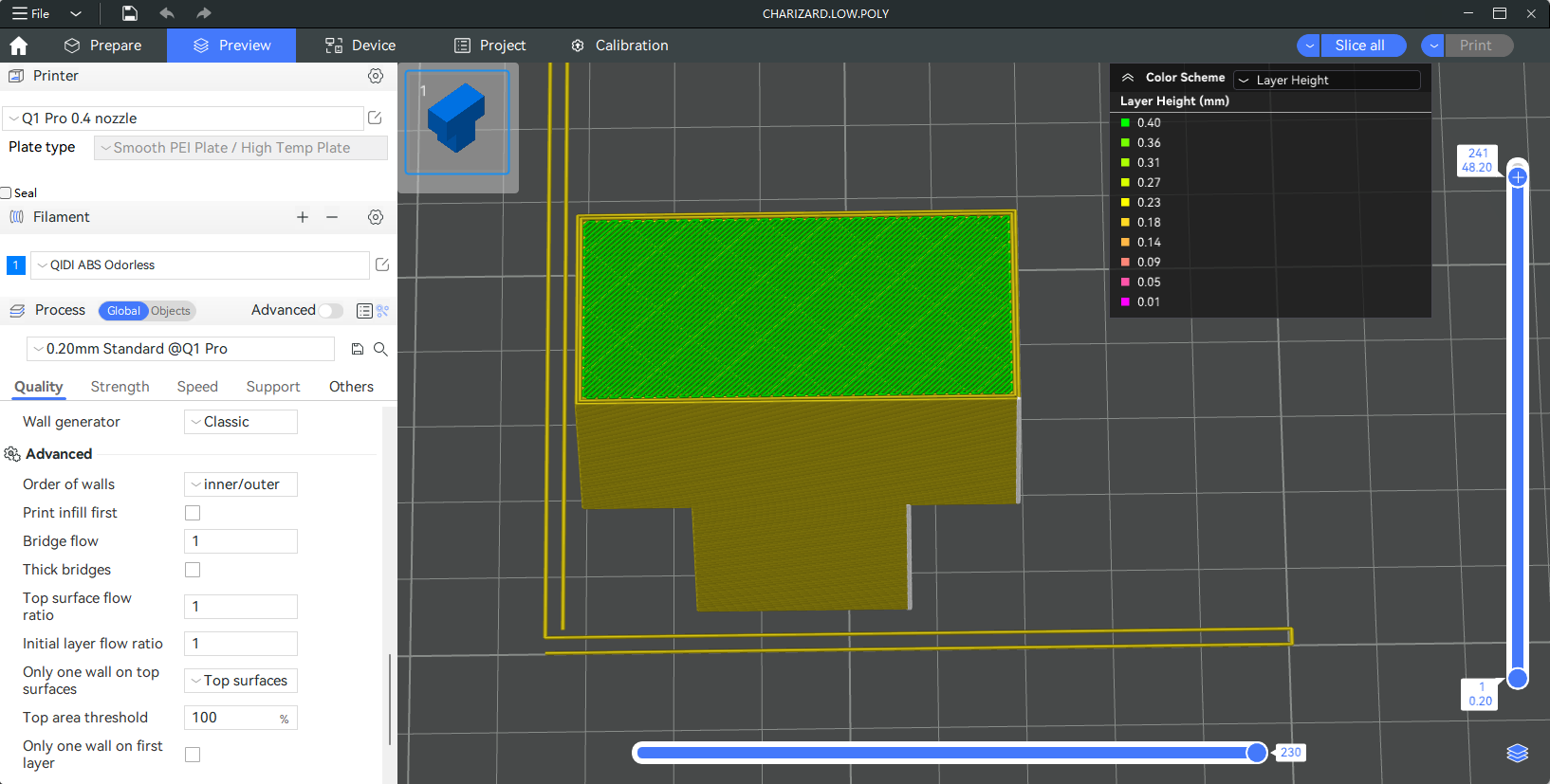

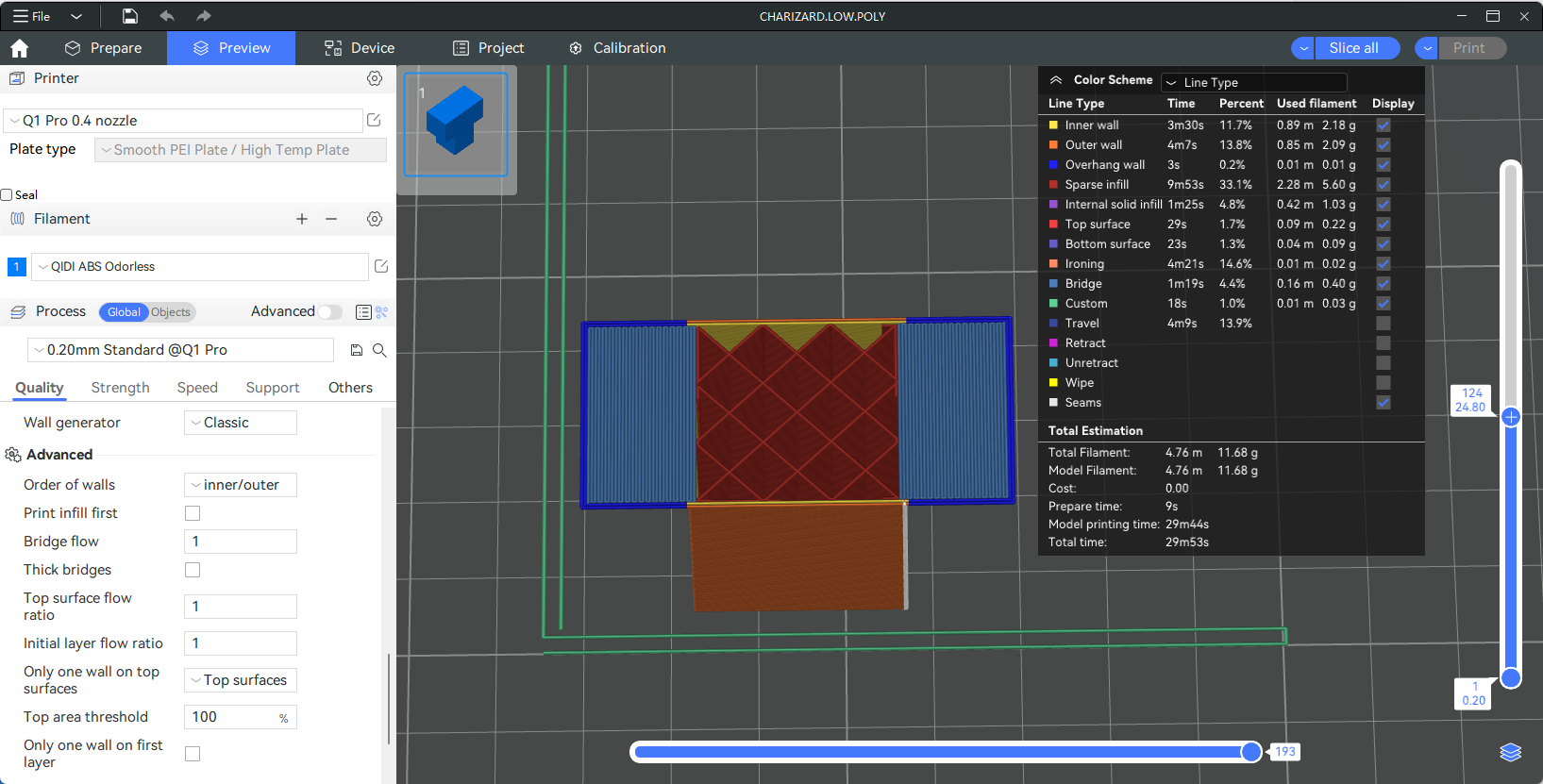

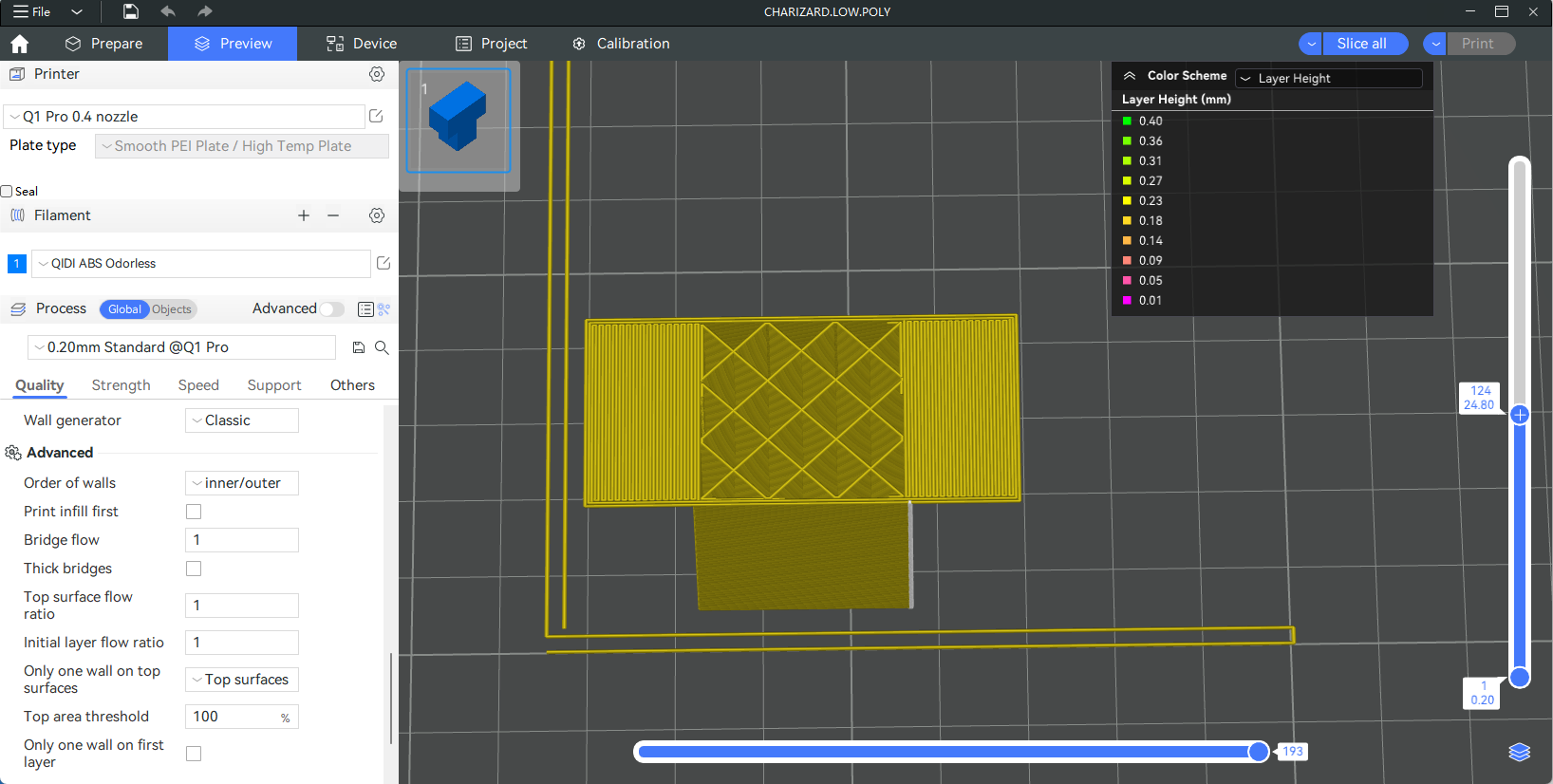

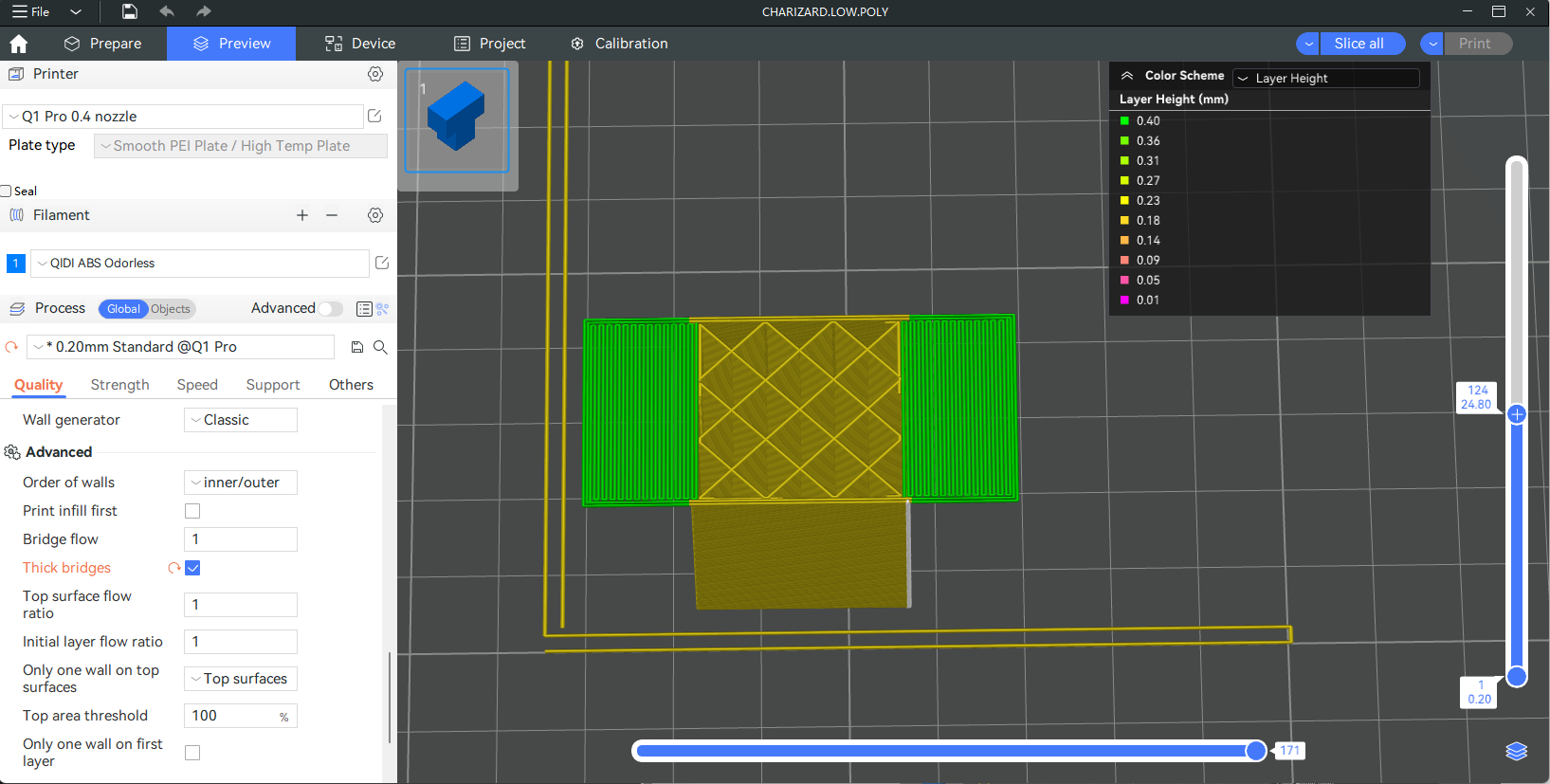

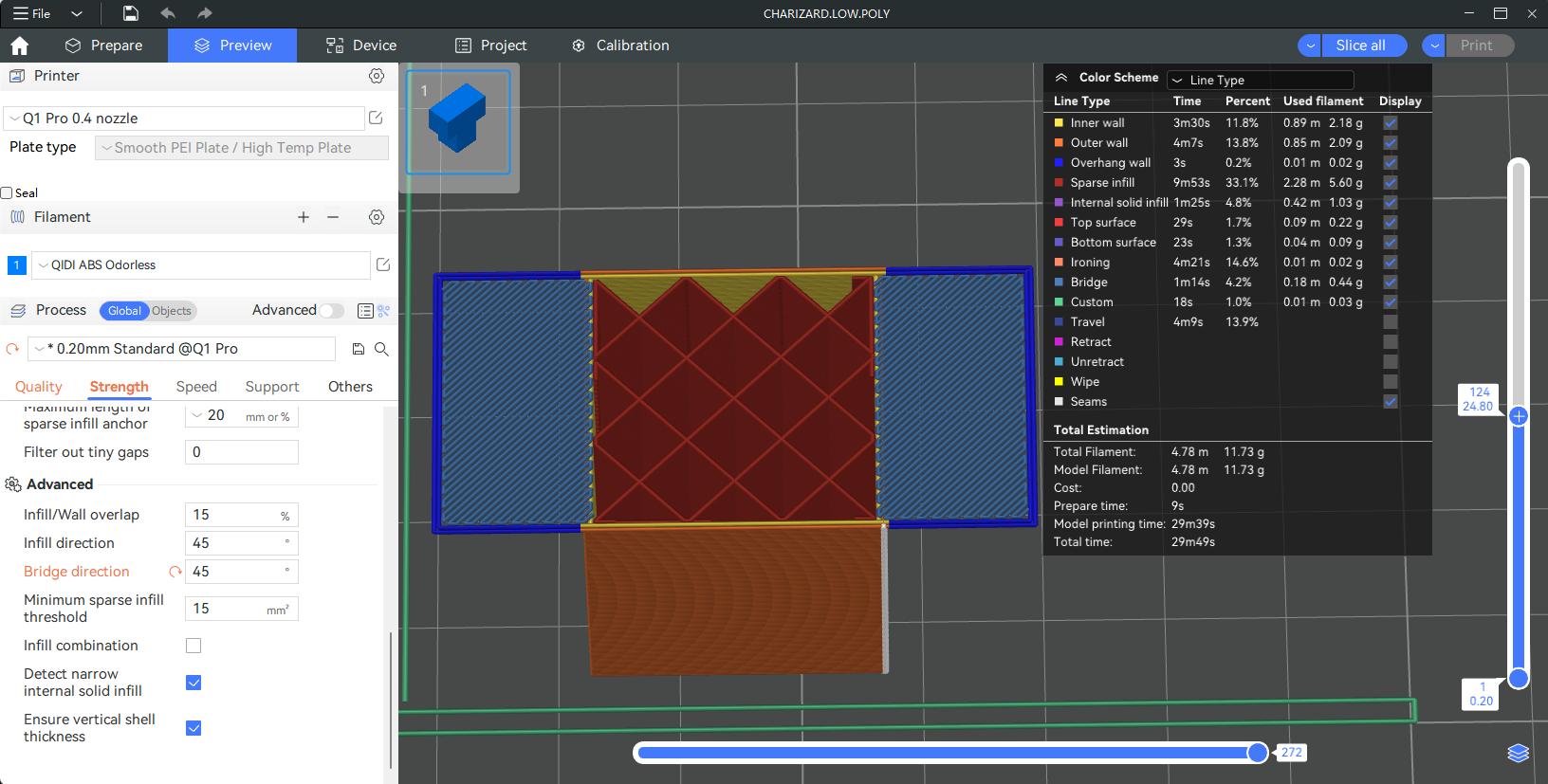

Below is a preview example of the different Bridges sliced with the 0.4mm nozzle:

-

The internal bridge is always the thick bridge, and the layer height and nozzle diameter in the preview are the same.

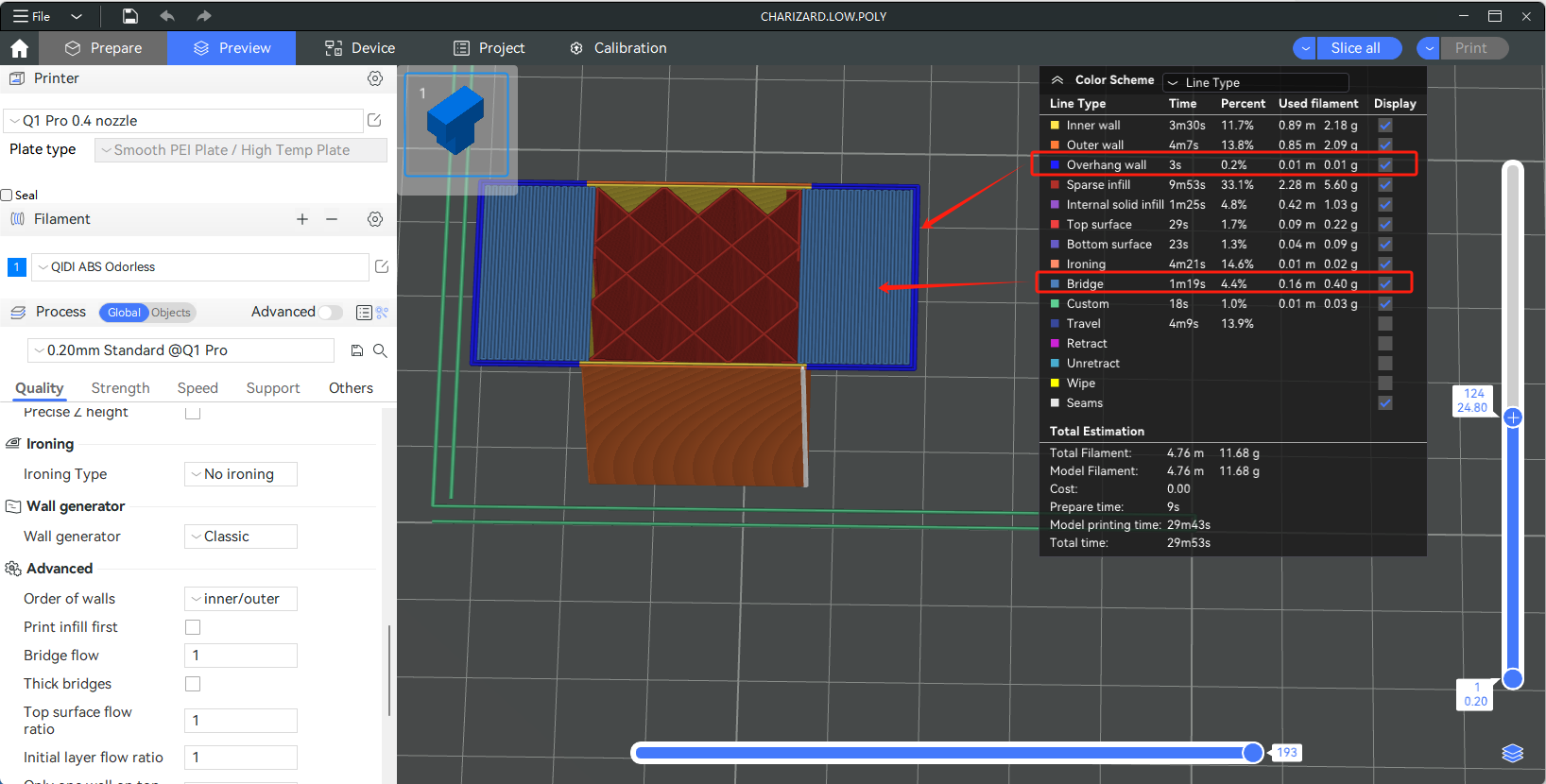

-

External bridge, thick bridge not enabled. The layer height in the preview is still the same as the height set, indicating that the bridge is extruded according to the flow calculated by the layer height and line width of the original line type. At this time, if the original layer height is small, the extruded bridge may be pulled apart due to insufficient material.

-

External bridge, thick bridge enabled. In the preview, the layer height and nozzle diameter are the same, indicating that the extruded bridge is a cylinder with the same diameter as the nozzle.

In all cases where the thick bridge is not open, the extruded flow rate of the external bridge is calculated according to the flattening state of the high line width. After the thick bridge is opened, the bridge flow is calculated according to the cylinder with the thick nozzle diameter and extruded.

So we can conclude,

- In all cases where the thick bridge is not open, the extruded flow rate of the external bridge is calculated according to the squashed state of the high line width. After the thick bridge is opened, the bridge flow is calculated according to the cylinder with the thick nozzle diameter and extruded.

- If the thick bridge is closed, the bridge looks thin, but only works for shorter bridging distances. And if the height of the original set is low, the bridge flow may be too small and cause the bridge to break.

¶ Bridge flow

Multiply the original bridged flow by the coefficient set here. If the thick bridge is enabled, the bridge flow of the thick bridge is multiplied by this coefficient. For example, set it to 0.9 to appropriately reduce the amount of bridge material to avoid sagging.

¶ Bridge direction

Set the bridge direction for the external bridge. If set to 0, the Angle will be calculated automatically. Otherwise, the external bridge will use the provided value. 180° indicates 0°.

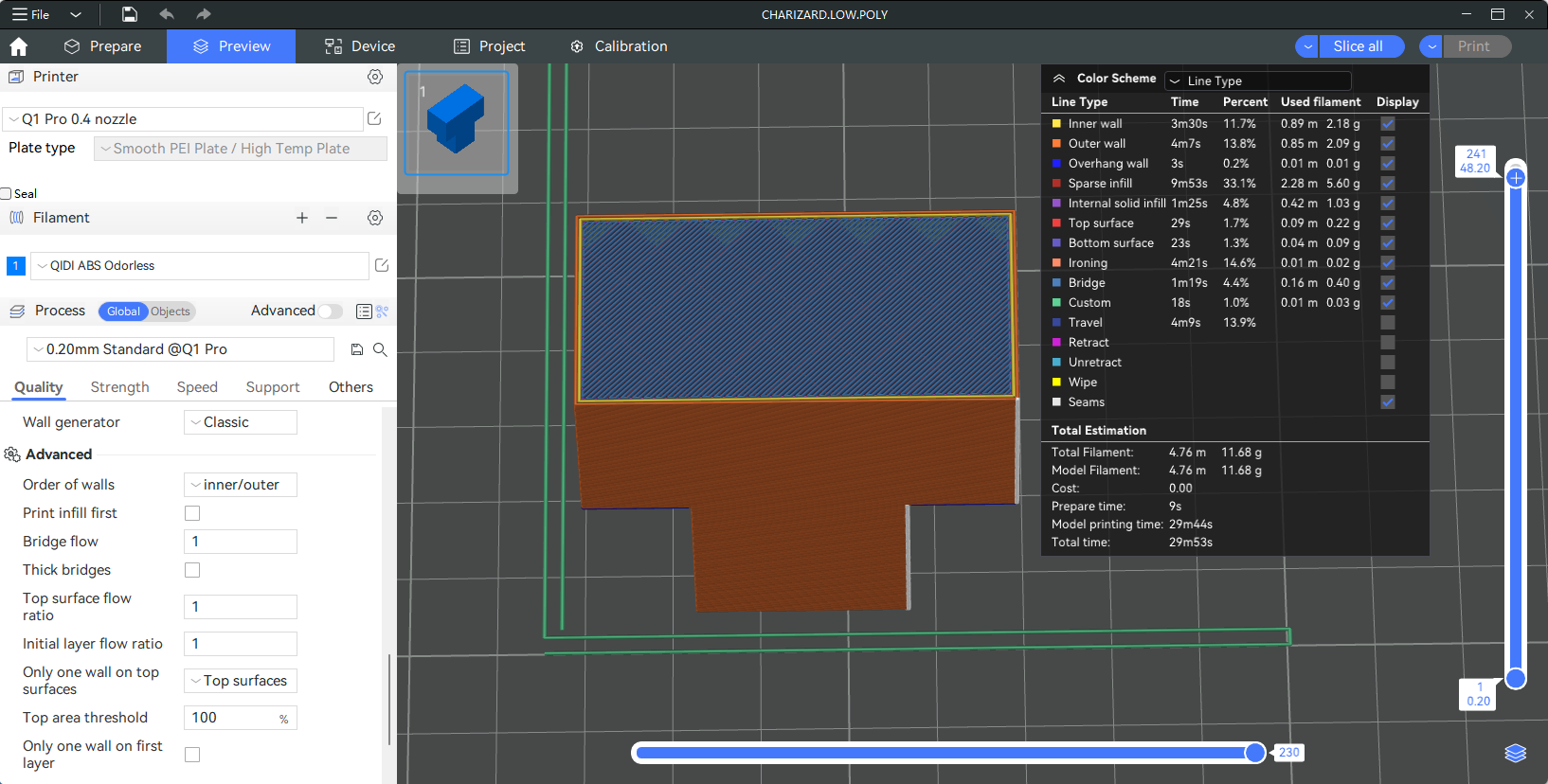

-

Bridge direction 45°:

-

Bridge direction 90°: