¶ Introduction

As we all know, limited by the forming principle of FDM 3D printing, we can see that the top surface of the printed model is composed of many lines, as shown in the following figure.

The ironing function, as the name suggests, is like ironing out wrinkles on clothing, eliminating lines on the top of the model and making the top look smoother. The working principle is that after printing the top surface of the model, the nozzle continues to print on the surface of the model with a small flow rate at the same height, allowing a small amount of extruded material to penetrate between the lines and fill the gaps. During the ironing process, because the Z height of the nozzle is not raised (the nozzle remains at the height when printing the top layer), the heat of the nozzle across the top layer will soften the top lines, and the small amount of extruding material can easily fill and smooth the top layer. The ironing process is shown below.

¶ Matters needing attention

Ironing can make the top layer of the model smoother, but there are some points you need to consider in advance:

-

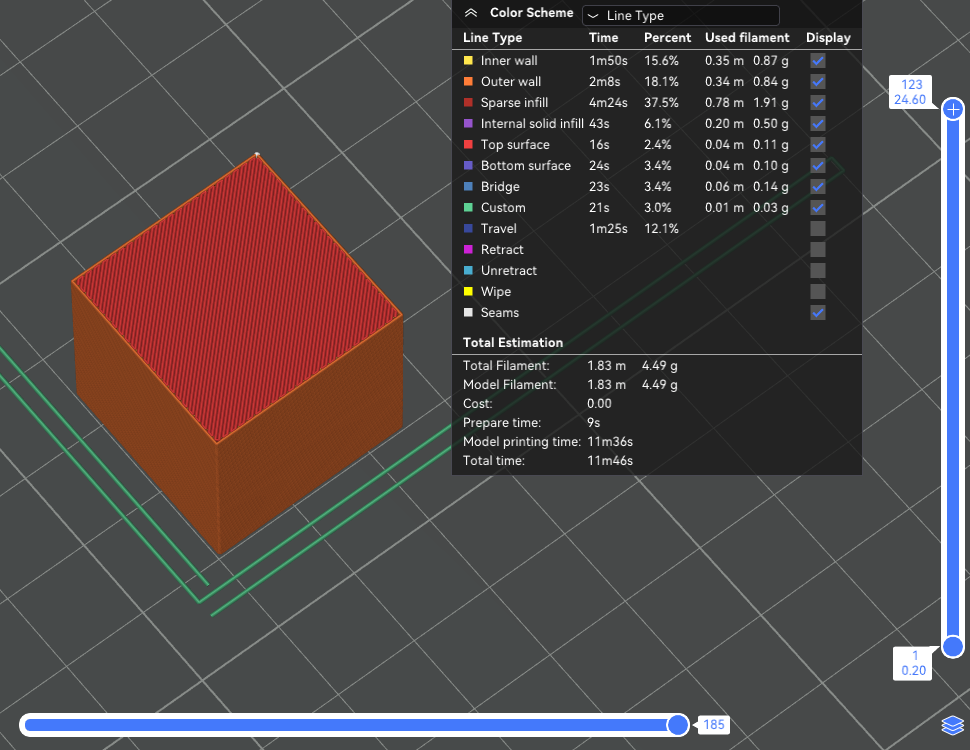

The ironing layer requires additional printing time to complete, and the ironing speed is usually slower, and if you print the model with a large top surface area, it may add quite a bit of printing time.

-

Because the ironing process uses only a small amount of extrusion flow and a slow printing speed, there is a certain probability of thermal creep, which can lead to hot end blockage, especially for materials with low softening temperatures such as PLA, PETG and TPU.

-

When ironing, the nozzle will rub over the top layer of the model, so the model will be subjected to greater force from the nozzle compared to normal printing. If the model is not firmly bonded to the build plate, it is likely to fall off the build plate and cause printing failure.

-

Choose the right ironing Settings to get a smooth surface, otherwise the effect may be worse, such as over extrusion, surface smoothness is inconsistent, etc.

-

Ironing is only effective when the top surface is flat. On the curved top surface, ironing will not be able to smooth out the lines between layers, so it may not necessarily achieve better results than not ironing, but rather increase printing time.

¶ Parameter settings

¶ Ironing type

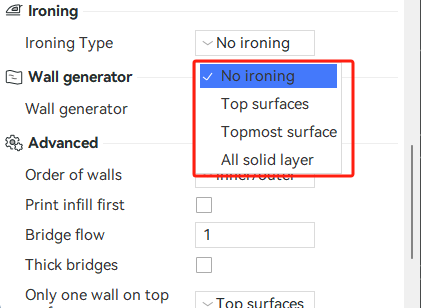

You can turn on this feature by checking in the "Ironing Type". Ironing is not enabled by default in QIDI Studio. Select options to turn on ironing. The specific explanation is as follows:

-

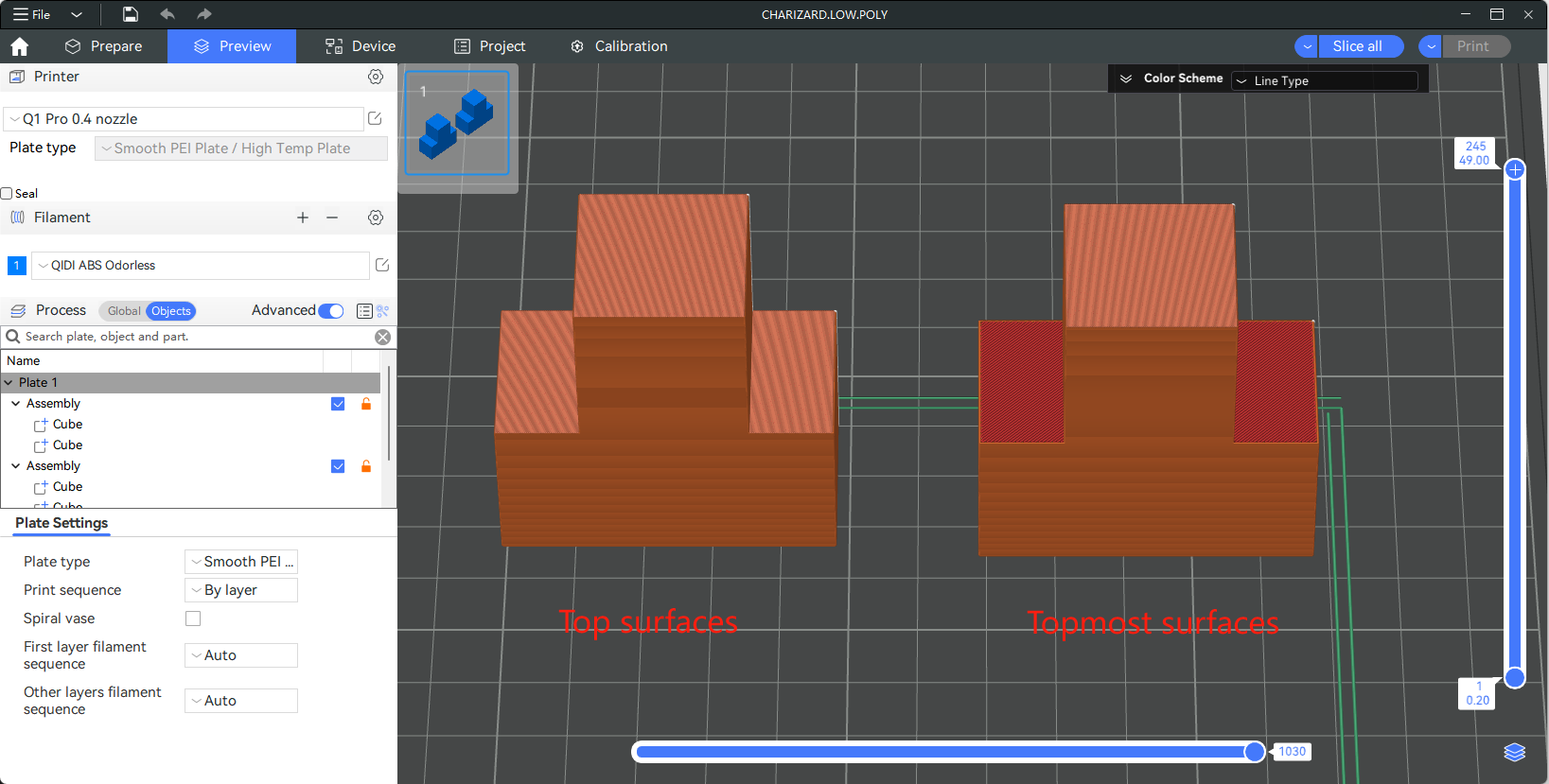

Top surfaces: All the top surfaces of the model will be ironed.

-

Topmost surface: Iron only the last layer of the model, the highest "top" layer. The difference between ironing all top surfaces and the topmost surface is as follows.

-

All solid layer: All solid layers (including top layers, bottom layers, and solid infill) will be ironed, which is rarely used because it does not necessarily produce good print quality but can take a lot of printing time.

¶ Ironing mode

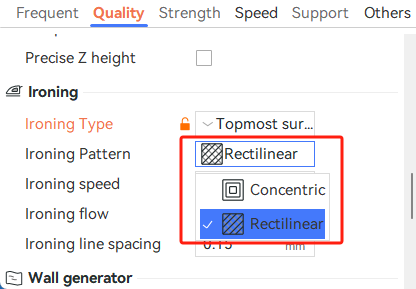

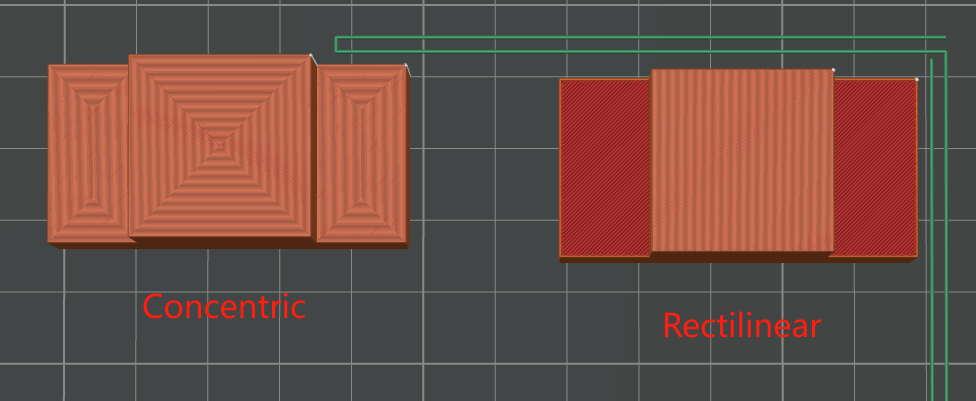

Two ironing patterns are available in the Ironing mode: rectilinear and concentric.

¶ Ironing speed

The ironing speed is the moving speed of the nozzle during the ironing process, usually a slower speed can obtain a better ironing effect.

¶ Ironing flow

This is the amount of material to be extruded during ironing. It is relative to the flow of normal layer height. Too high a value will result in over-extrusion on the surface. Too small a value can also cause the ironing surface to not be smooth enough.

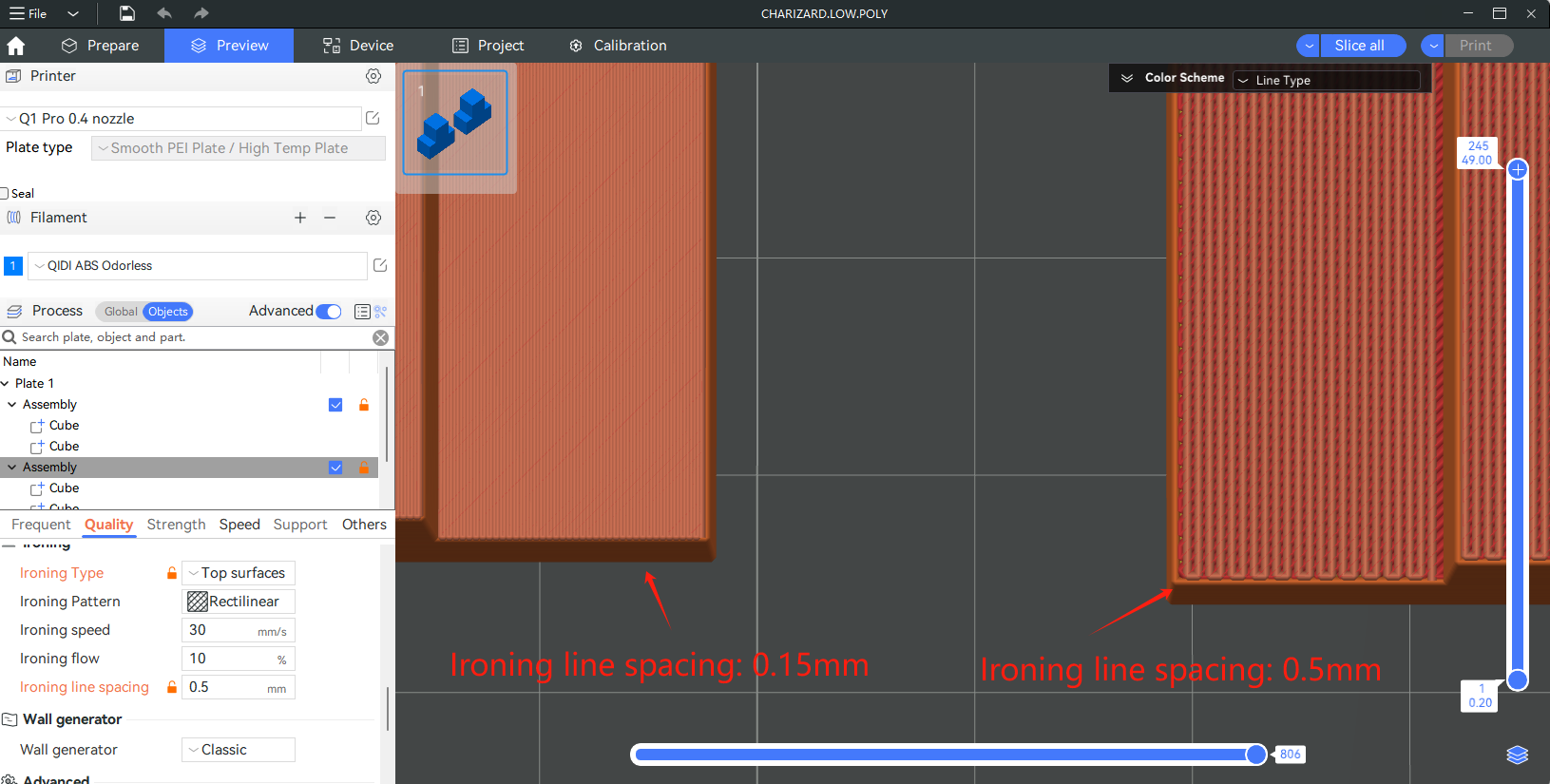

¶ Ironing line spacing

The spacing of the ironing line, the larger the value, the greater the spacing of the nozzle ironing path. It is usually recommended to be smaller than the nozzle diameter so that the same area can be repeatedly ironed multiple times.

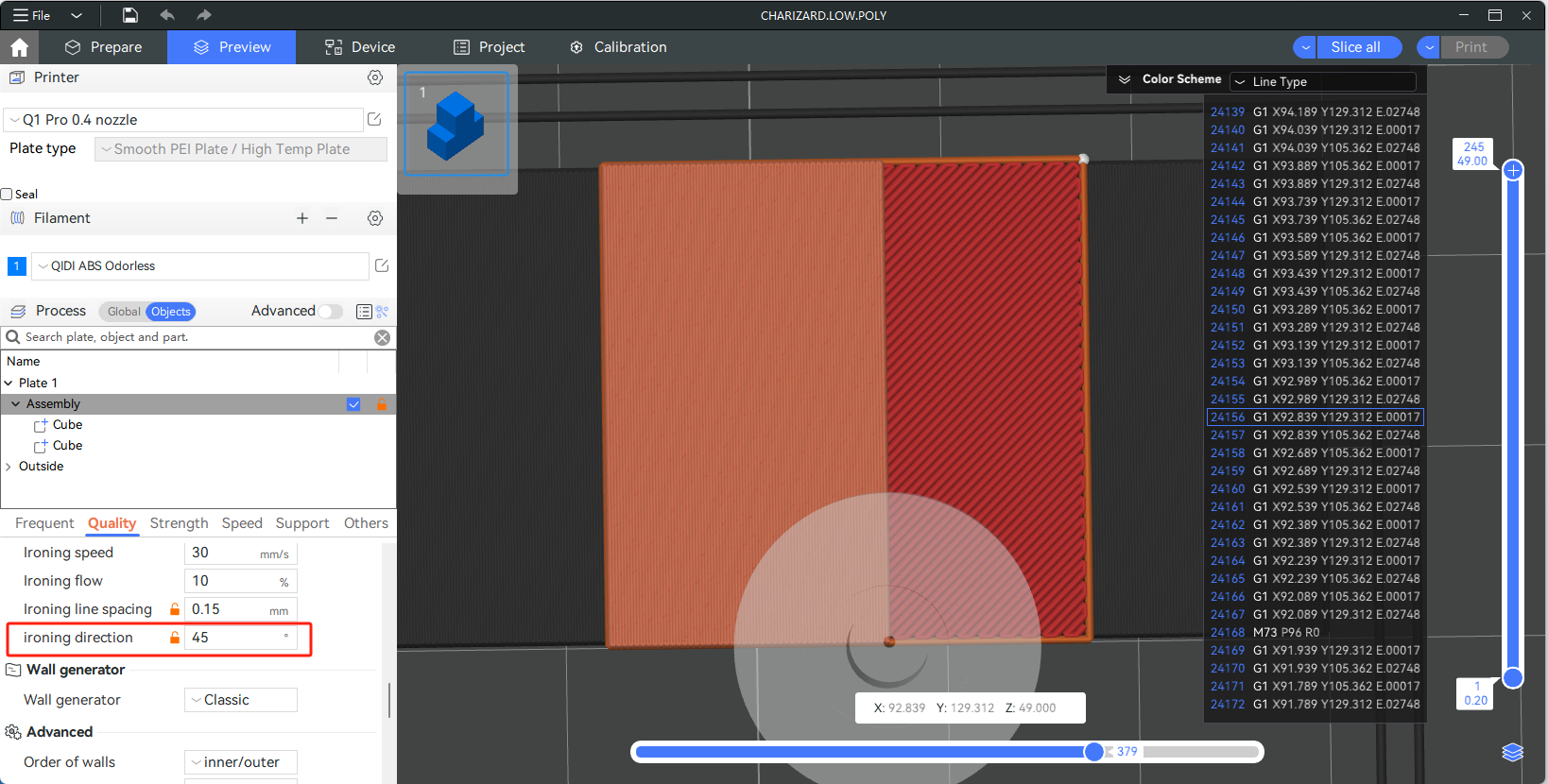

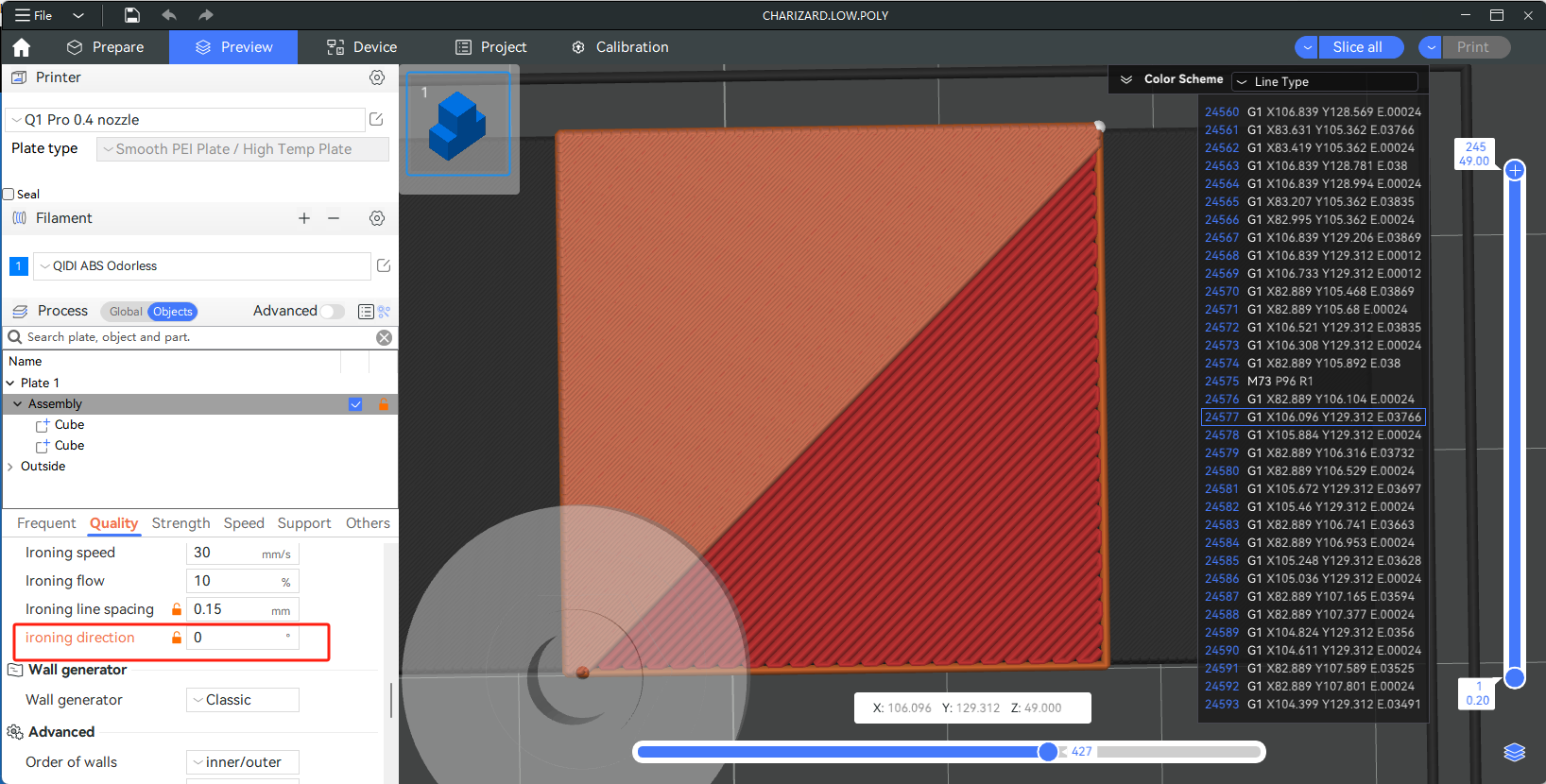

¶ Ironing direction

If you want to adjust this parameter, please make sure that "Develop mode" is enabled in the "Preferences".

The value indicates the relative Angle between the ironing line and the top pattern line, usually 45° Angle can obtain a better ironing effect, as shown in the figure below.