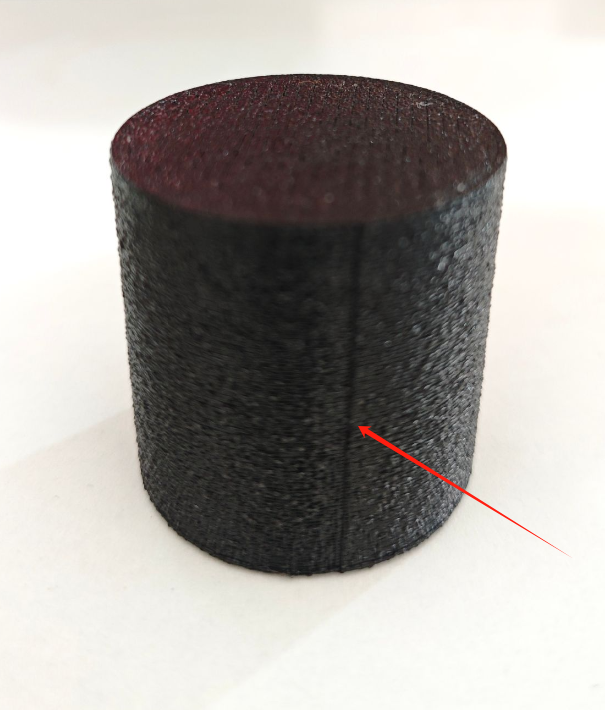

Seams are gaps formed at the junctions where each path of printing starts and ends during the printing process. They result in vertical seams on the surface of the model. In FDM 3D printing, these seams are inevitable, especially on models with curved surfaces, where the seam traces on the surface can be quite noticeable.

¶ Introduction

¶ Auto-seam options

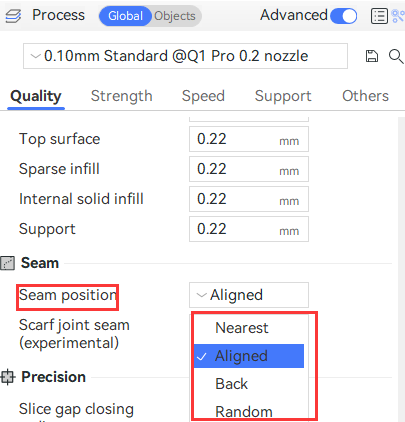

For better print quality, the seam position can be set in the process presets. There are four types of seam positions to choose from: Nearest, Aligned, Back, and Random.

¶ Nearest

“Nearest” first finds all possible candidate positions by the following priority: concave non-overhang vertex > convex non-overhang vertex > a non-overhang vertex > overhang vertex.

That is, it will preferentially select concave or convex non-overhanging vertices to make the seam position better hidden. If your model has sharp corners, this will make the seam effectively invisible.

However, if the current layer does not have either of these vertices available, it selects from among the other candidate non-overhang vertices so that it is closest to the end of the previous print path. As a result, this option optimizes the traveling path to minimize the impact of filament stringing.

¶ Aligned

The seam placing logic is the same as “Nearest” for finding the candidates, but it will choose the one that is nearest to the start point of the previous layer. This will ensure the seam is mostly aligned throughout the whole object.

¶ Back

The seam will be set behind the model.

¶ Random

Random seams will select a different location on each layer to place the seams, making the seams look less uniform and less obvious than "aligned" or "back". However, it can cause the appearance of many small white dots on the surface of the model.

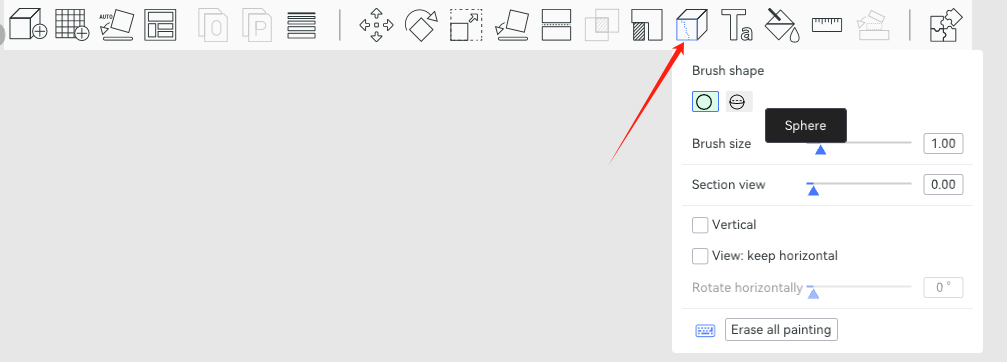

¶ Manual-seam painting

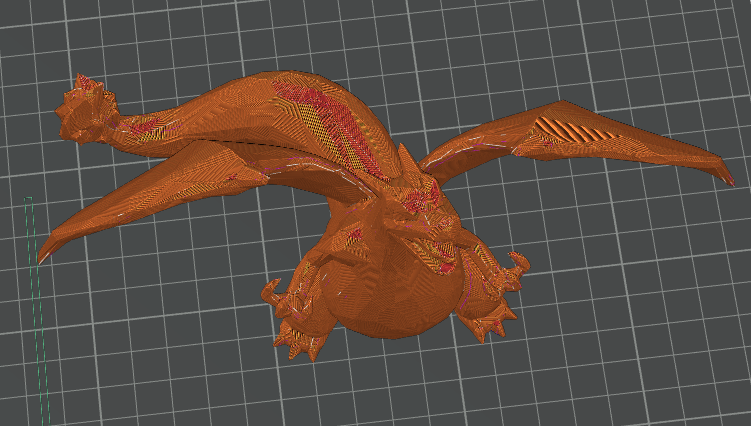

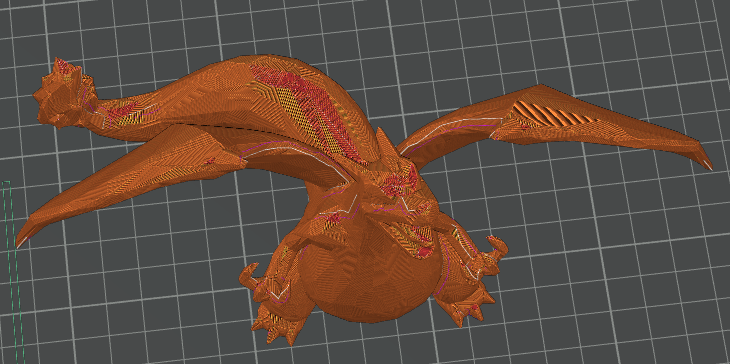

Sometimes the auto seam position may be not ideal, you can customize the seam position by manually painting the method.

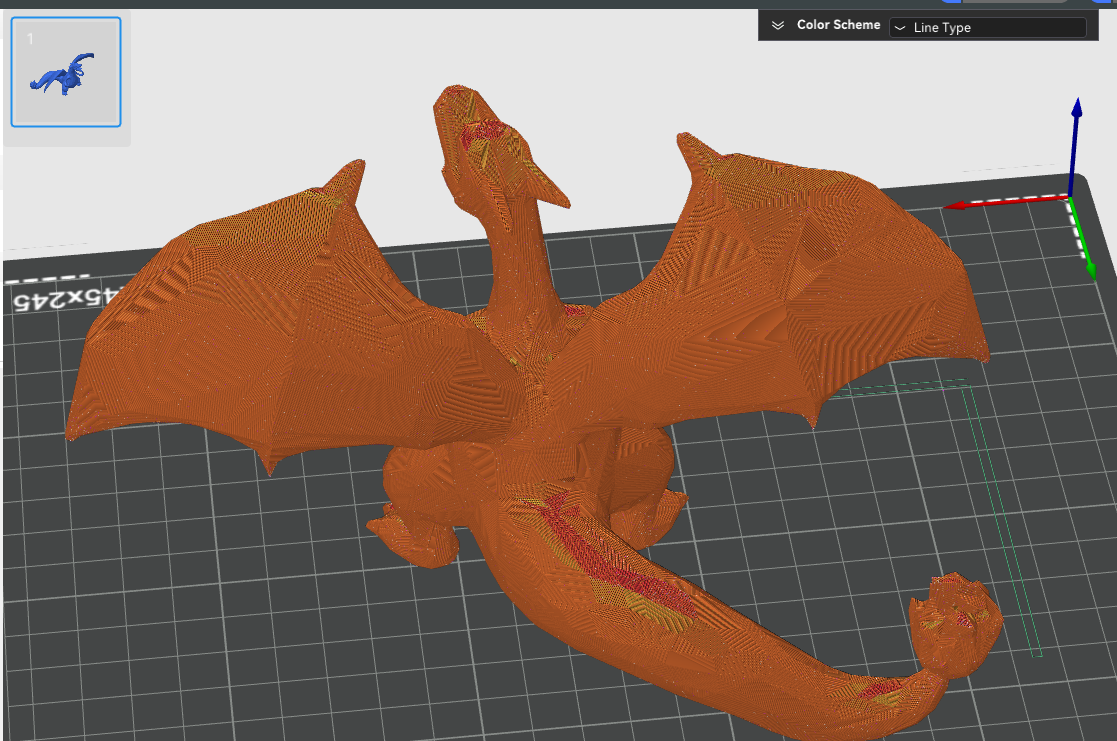

Specific operations are shown in the following GIF:

The model in the above image is from Charizard LOW-POLY