¶ Overview

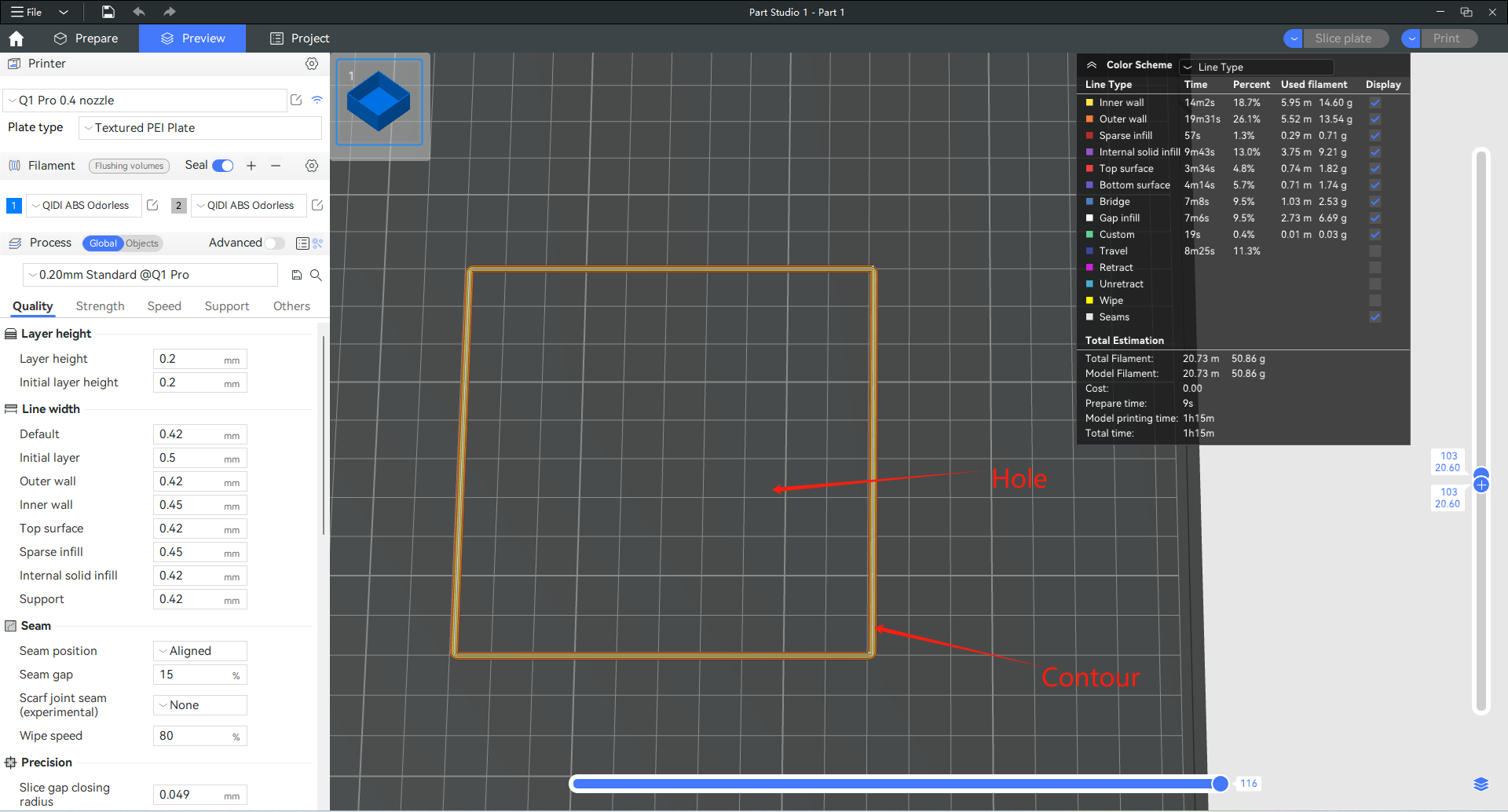

When you print some parts that need to be assembled, sometimes the size of the parts printed will be incorrect because of factors such as the shrinkage of the material, so the parts can not fit well. The XY hole/contour compensation function in QIDI Studio can properly compensate for the gaps caused by errors. You can enable this feature in Process - Quality:

¶ Operation

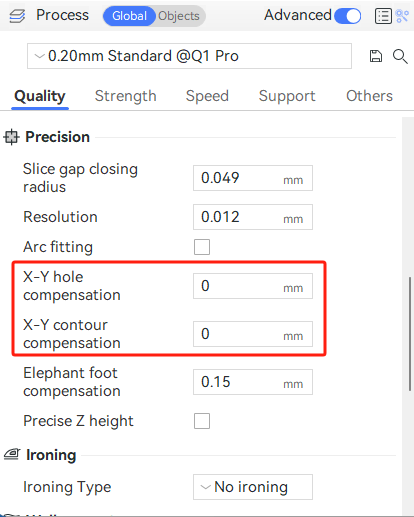

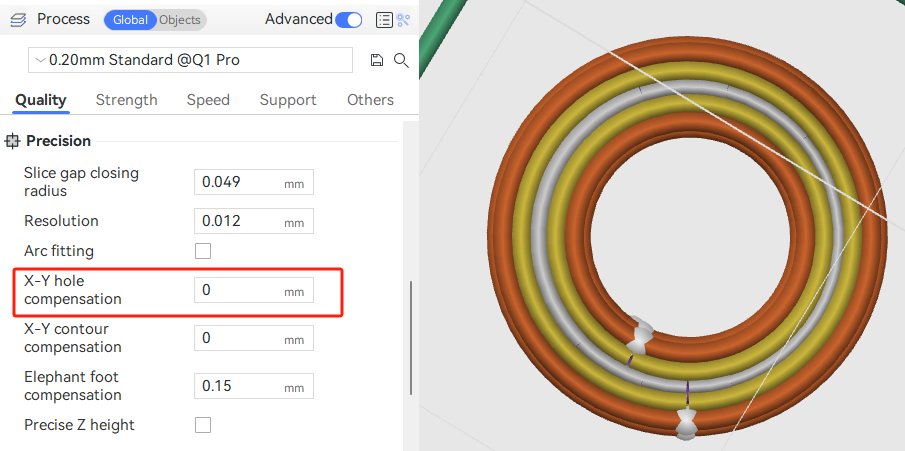

¶ XY Hole compensation

Hole compensation can add a compensation amount for each hole in each layer of the XY plane. When printing holes, the nozzle may drag some material toward the center of the circle, causing the actual printed hole to be slightly smaller than its intended value. If a hole is measured to be 0.5 mm too small, a suitable size hole can be printed with compensation of +0.25 mm.

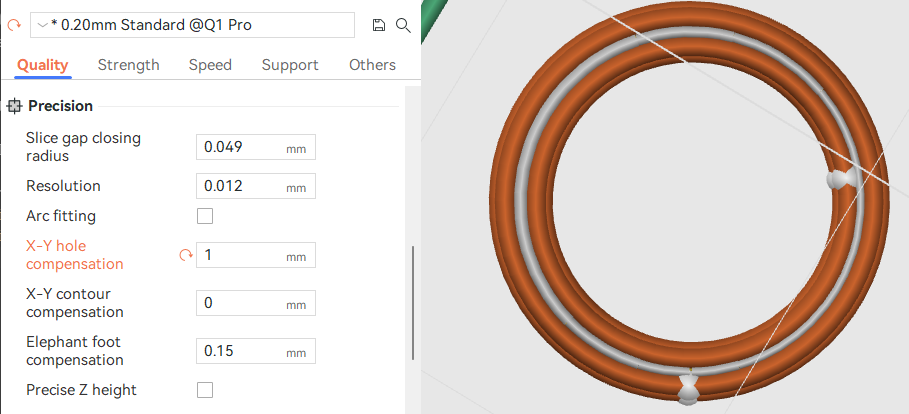

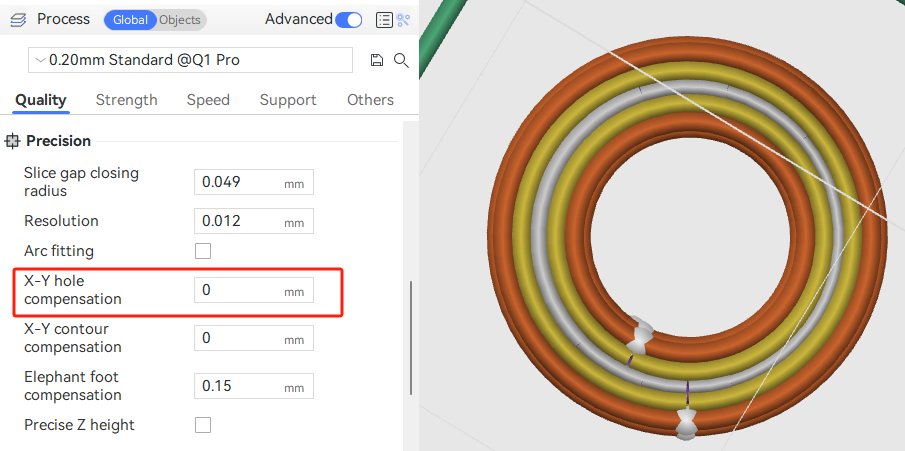

To make this more clear, the following three figures are the comparison of the hole compensation of -1mm, +1mm, and the original size. It can be seen that hole compensation only changes the size of the circular hole in the middle, and the size of the outer contour remains unchanged.

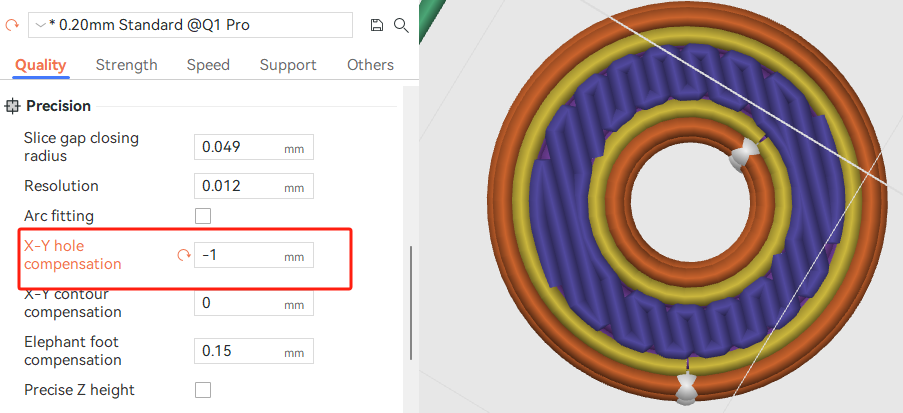

¶ XY Contour Compensation

The XY contour compensation function will allow you to adjust the size of the model contour on the XY plane. It essentially increases or decreases the size of the model in the XY plane. Positive values are used to expand the XY dimension of the object, while negative values are used to shrink the XY dimension of the object.

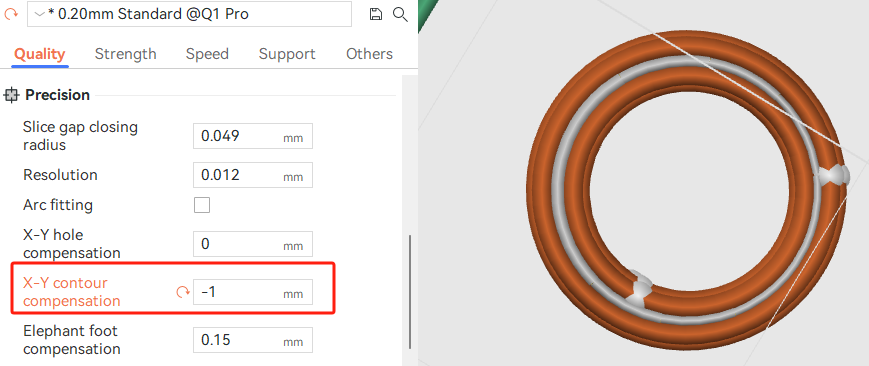

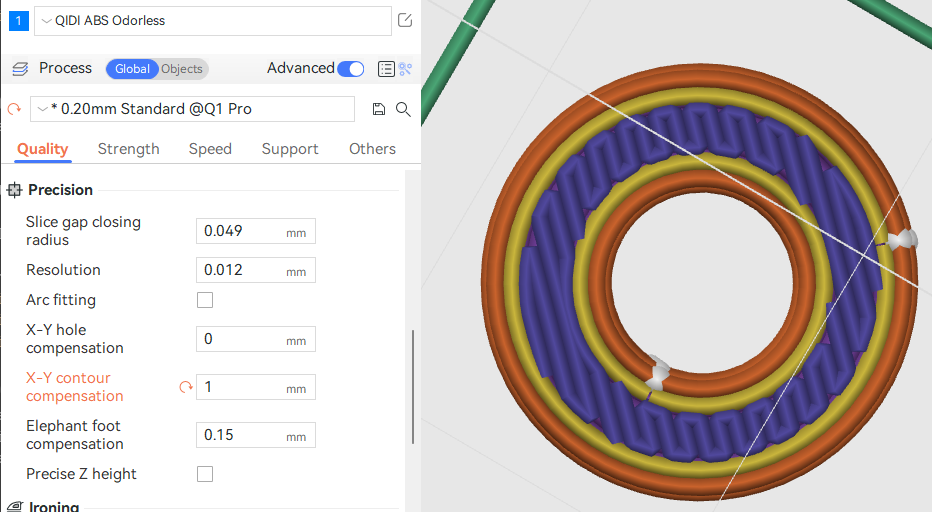

To make this more clear, the following three figures are the comparison of the external contour compensation -1mm, +1mm, and the original size. It can be seen that the external contour compensation is to expand the solid part outward or inward, and the size of the middle hole is unchanged.

¶ Definition of holes and Contours

When compensating for XY holes/contours, compensate for the holes and contours within each layer. Within a single layer, the closed and internally hollow are "holes", while the rest are "contours".