¶ Introduction

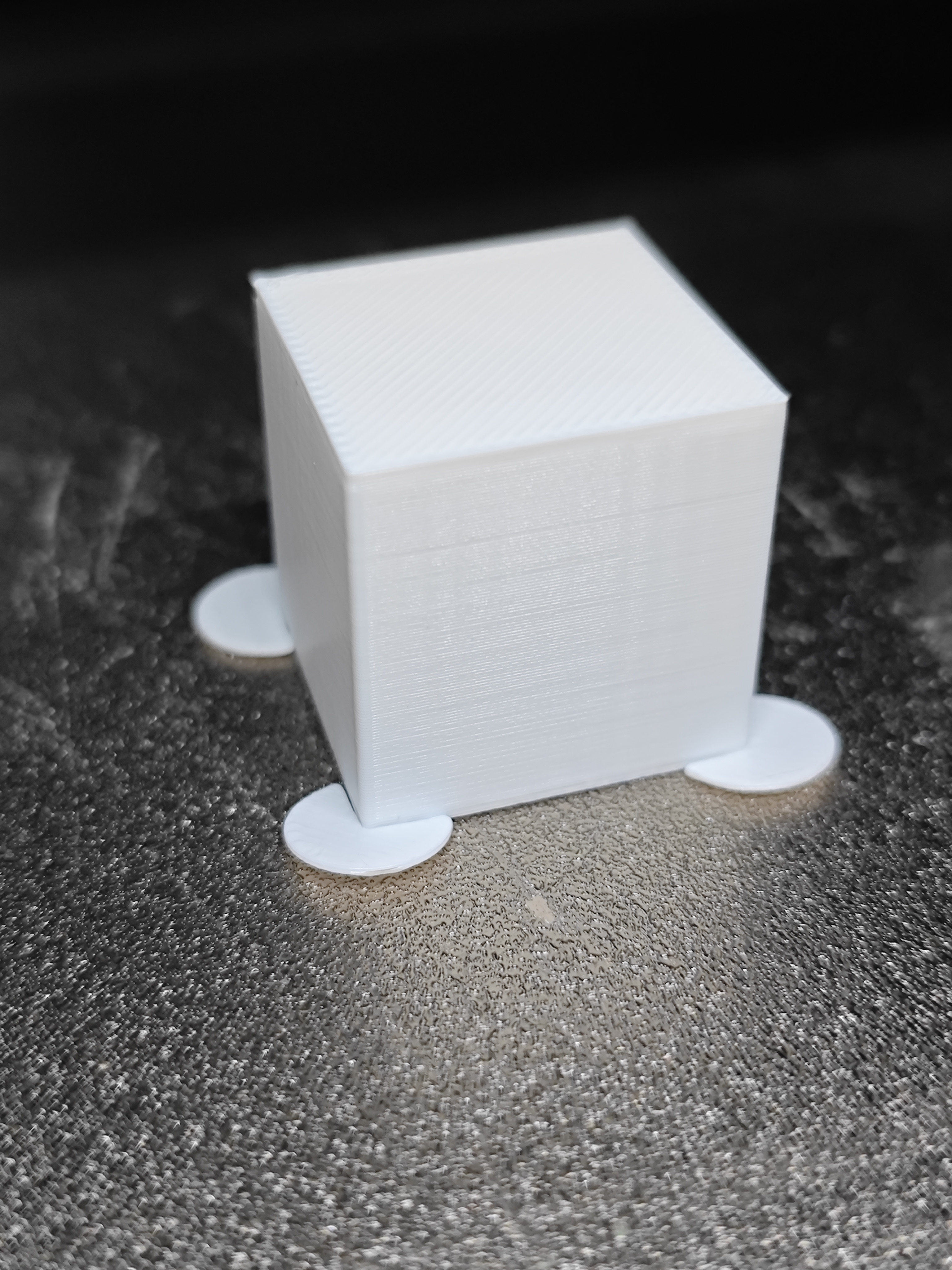

During the 3D printing process, the printed model often experiences warping due to shrinkage of the material or insufficient adhesion between the object and the build plate, especially when printing materials that are prone to shrinkage such as ABS or ASA.

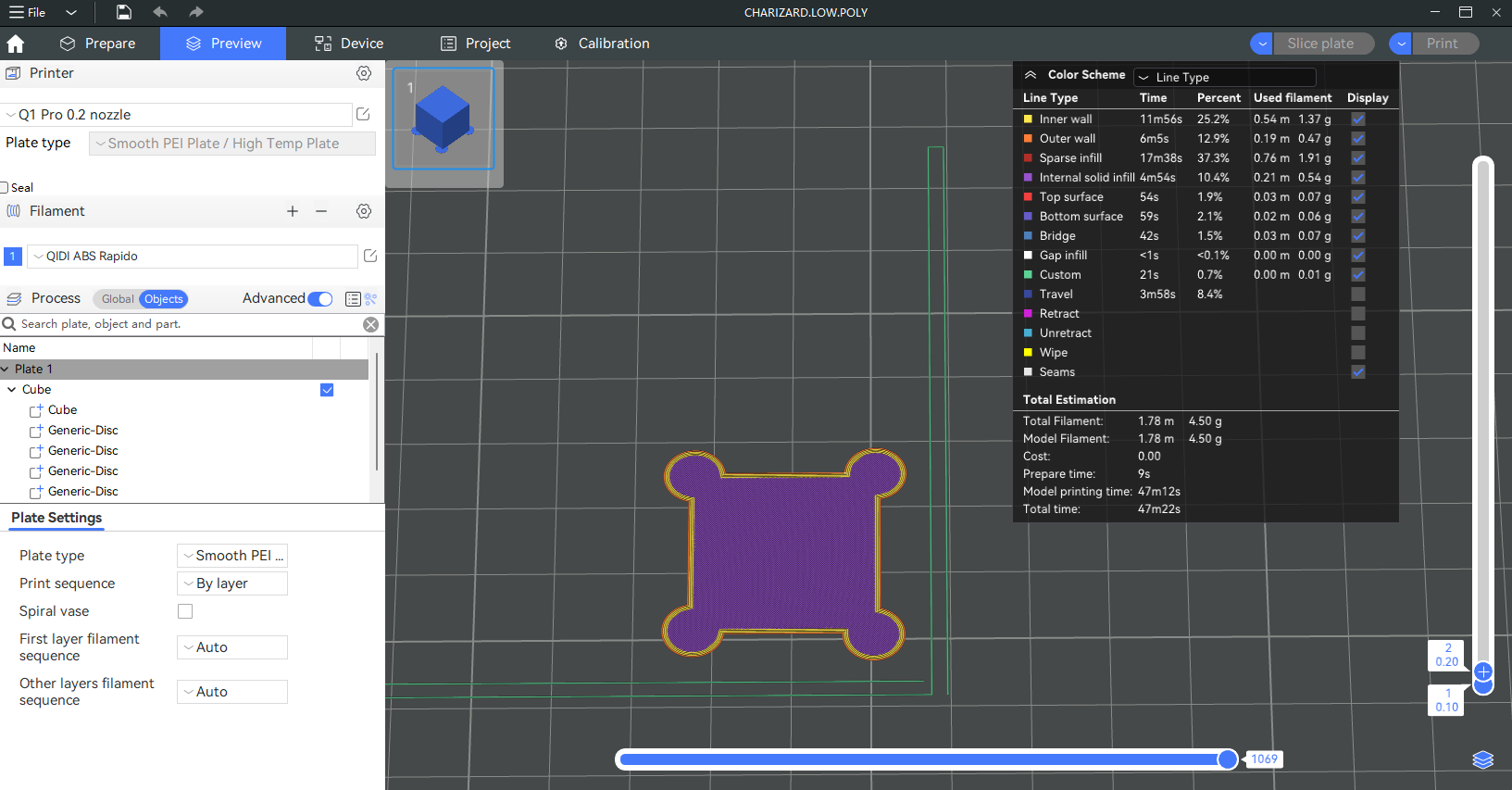

In QIDI Studio, you can improve the issue of warping edges during printing by adding small discs locally to the model.

¶ Operation

-

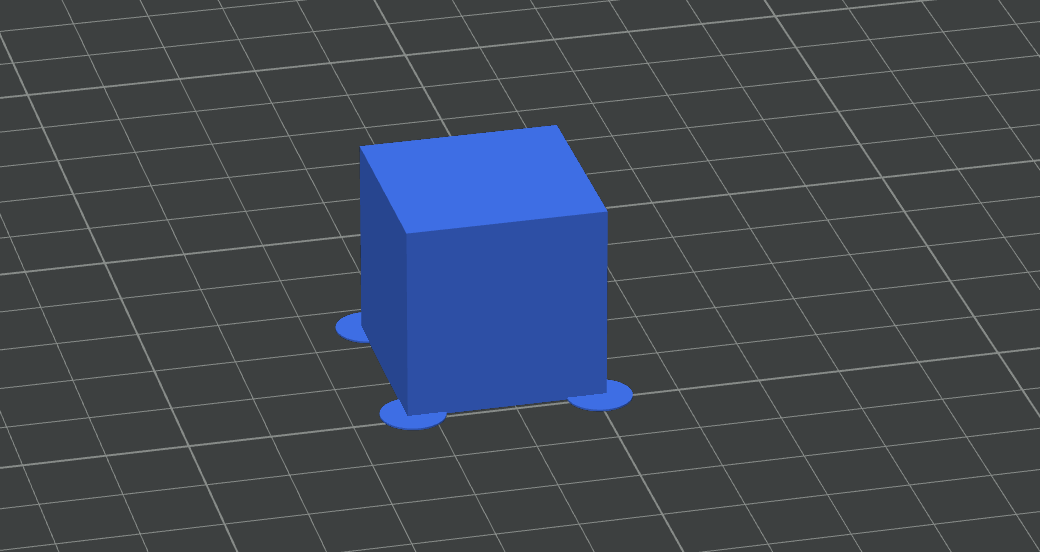

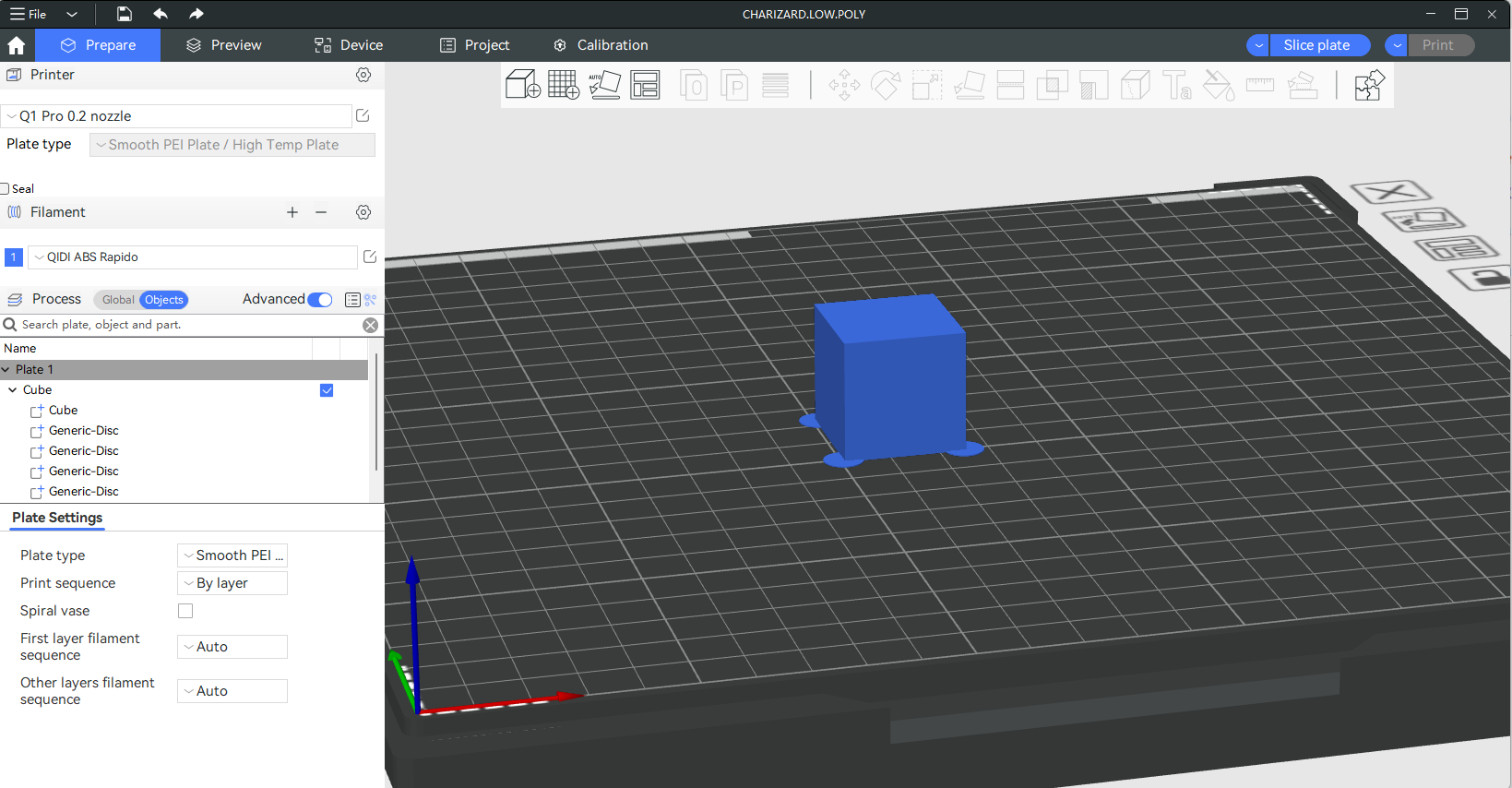

First, right-click the cube on the build plate, select “Add part” — "Disc", and adjust it to the appropriate size.

-

Repeat the above steps, placing small discs on all the model's corners prone to curling.

-

When you click "Slice," you'll notice that the small discs and the cube have the same number of wall loops. Therefore, the software interprets them as integrated. Additional settings are required to separate the small discs from the cube so that they can be easily detached after printing is completed.

-

Adjusting the number of wall loops for the small discs can differentiate them from the cube.

-

At this point, the discs and cube have been separated, but the overlapping part after slicing retains the disc part instead of the cube part. You can drag the cube to the end of the object list so that after slicing, the overlap between the cube and the discs will retain the portion of the cube. Because in the object list, multiple parts of the same object are ranked lower on the parts list and have higher priority. If there are overlapping parts, the higher-priority parts will be retained.

-

In some printer presets the default value for elephant foot compensation is not 0. After slicing using the above method, due to the shrinkage caused by elephant foot compensation, the junction between the cube and the discs will protrude slightly compared to the side. You can set the elephant foot compensation to 0 and slice again.

Following the above methods can effectively address the issue of model sensitivity to boundary points.