The model warping, falling off or collapsing is usually caused by local shrinkage of the model and insufficient adhesion to the printing plate. The surface of the model will have a convex transverse grain after warping, which is due to the smaller distance between the warping area and the nozzle, resulting in the extrusion line of the layer being flattened and spilled during printing. Model warping may also cause the surface of the model to appear uneven, and even print failure.

¶ Possible causes and solutions

1. The model is too thin and tall

When the model is too thin and tall, its center of gravity is high, and it may wobble during the printing process, eventually causing the model to fall off or collapse.

-

Hand drawing adds support to the model;

-

Reduce printing speed and acceleration;

-

Change the placement of the model to minimize the height of the center of gravity of the model;

-

Cut the model.

2. Nozzle hits model

-

When the temperature of the nozzle is insufficient and at high speed printing, the consumables in the nozzle are not sufficiently melted, resulting in poor flow of the extruded consumables, which is easy to cause the nozzle scratching model. In this case, it is recommended to raise the nozzle temperature appropriately.

-

Excess material sticking to the nozzle or model may also cause the nozzle to collide with the model during the printing process. In this case, it is recommended to pause the printing, clean the nozzle and resume printing at a lower temperature and speed.

-

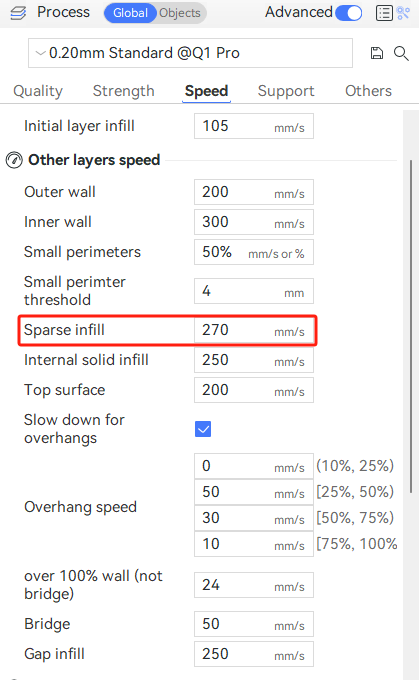

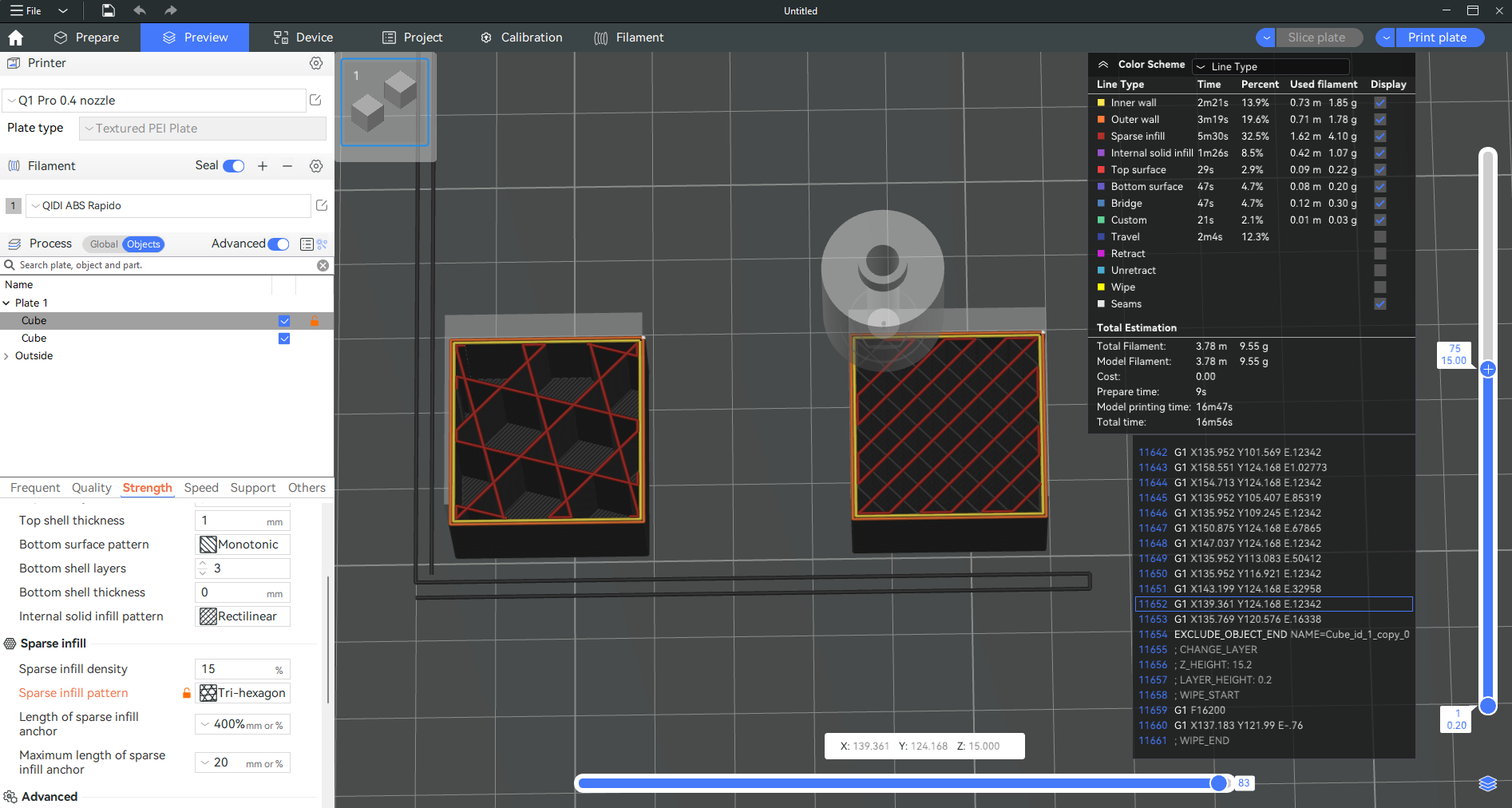

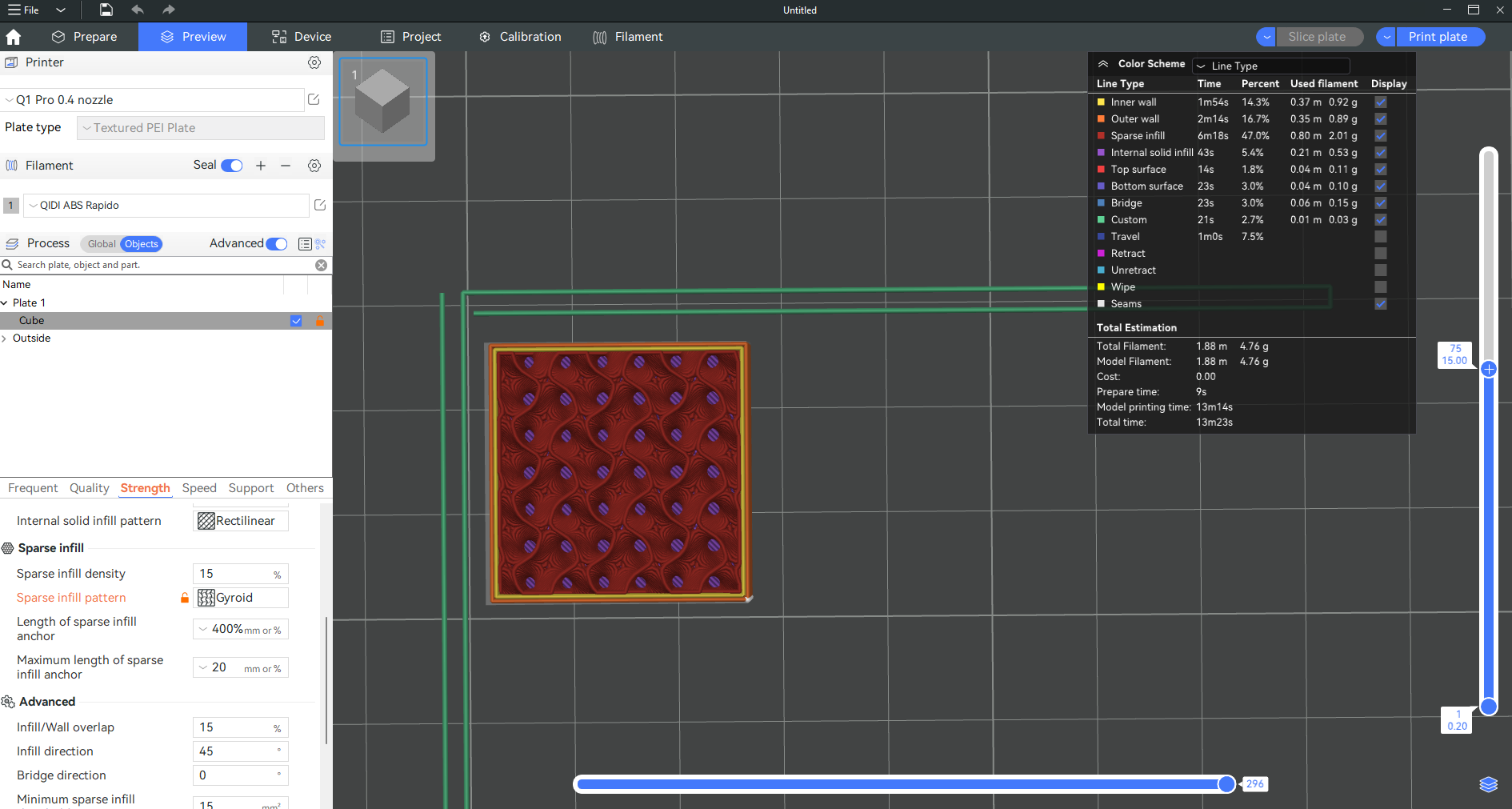

Filling methods with crossed lines within a single layer can also cause the nozzles to scratch against the model at the crossing points (such as filling patterns such as grids and triangles). When the filling pattern affects the adhesion effect of the model, you can try to reduce the printing speed of the filling, or modify the filling pattern to a single layer without intersections, straight lines, etc.

3. Local warping of the model is usually caused by insufficient adhesion between the model and the hot bed, excessive cooling of the model or excessive local shrinkage of the model. The larger the model size, the easier it is to shrink, and the higher the filling rate, the easier it is to shrink. At the same time, ANS, ASA, PC, POM, PP and other consumables are more easily warped than PLA, PLA-CF, PETG and so on.

-

The low temperature of the hot bed results in insufficient adhesion between the model and the hot bed. The hot bed temperature can be properly increased manually to solve the problem.

-

The chamber temperature is low, the fan speed is too fast, resulting in the model cooling speed is too fast - you can appropriately increase the hot bed temperature, close the printer door and top cover, and adjust the speed of the small fan.

-

If the model size is large and the fill rate is too high, the fill rate can be reduced appropriately (the default value is 15%). In addition, the filling pattern is more likely to shrink with a straight line, and the filling pattern can be changed to a spiral to reduce the risk of shrinkage. For some structural parts with relatively high strength requirements, the number of layers of the wall can be set to 5, and the filling rate can be set to about 30%. Models with low strength requirements can directly choose the default number of wall layers and filling rate.

4. Insufficient adhesion between the model and the printing plate

-

The build used for printing does not match the "printing board type" selected in the slicing software. The same material is printed on different hot bed printing boards using different hot bed temperatures. If the type of printing board is selected incorrectly, it may be due to insufficient adhesion due to the insufficient temperature of the printer's hot bed.

-

Improper levelling of the first floor. You can clean the printing board and nozzle first, then use the printer's automatic leveling function to level the printing board, and then print.

-

Printing board dirty or wear - use water or detergent to clean the large negative rod, if the printing board wear is serious, it is recommended to replace the printing board.

-

Insufficient Brim - Draw Brim manually.

-

Incorrect gluing - Apply evenly to the surface of the printing board.

-

The hot bed temperature is low -- appropriately increase the hot bed temperature.