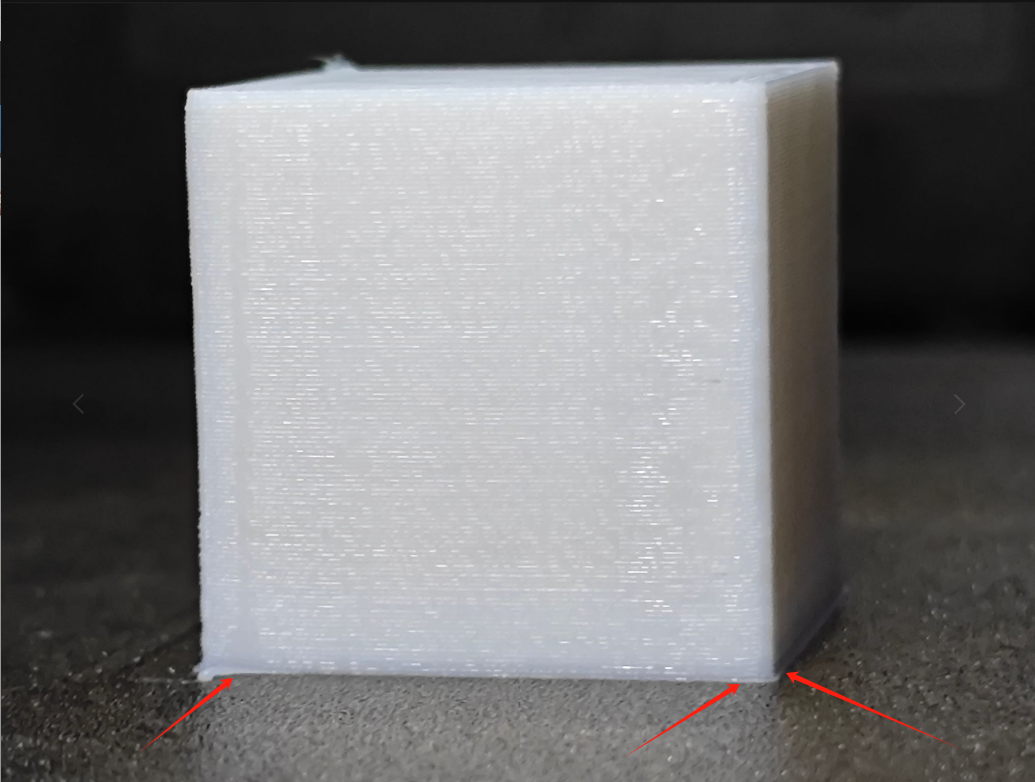

¶ What is the elephant foot?

In FDM 3D printing, the material is extruded layer by layer through the nozzle to construct the 3D model. So during the printing, the first layer of extruded filaments is pressed onto the heat bed and has not yet fully cooled. In addition, the compression from the upper layer of gravity may cause the printed first layer to expand, which is called elephant foot. When printing larger models, the elephant foot is usually more visible.

In most cases, the slight elephant foot at the bottom may not be significant for most models. However, when the printed model needs to have precise dimensions and tolerances for assembly, you need to do some post-processing on the elephant foot.

¶ Operation

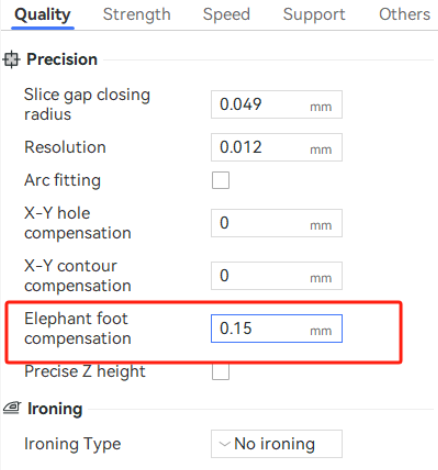

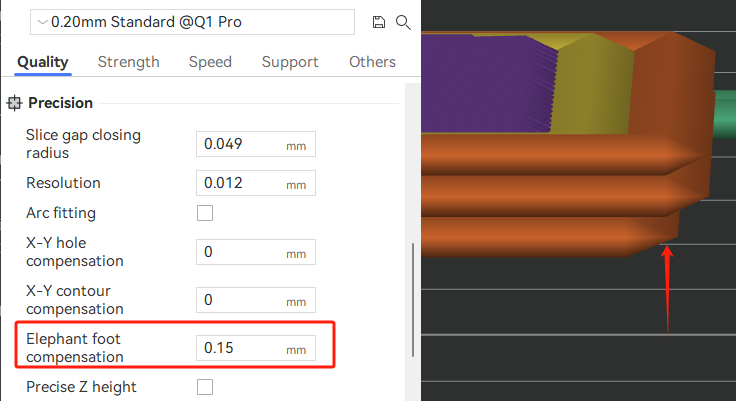

When the foot compensation function is enabled in QIDI Studio, it will actively shrink the first layer to compensate for the expansion of the first layer, so that the actual printed model's first layer is aligned with the other layers. This eliminates the need for you to manually polish the extended edges of the first layer.

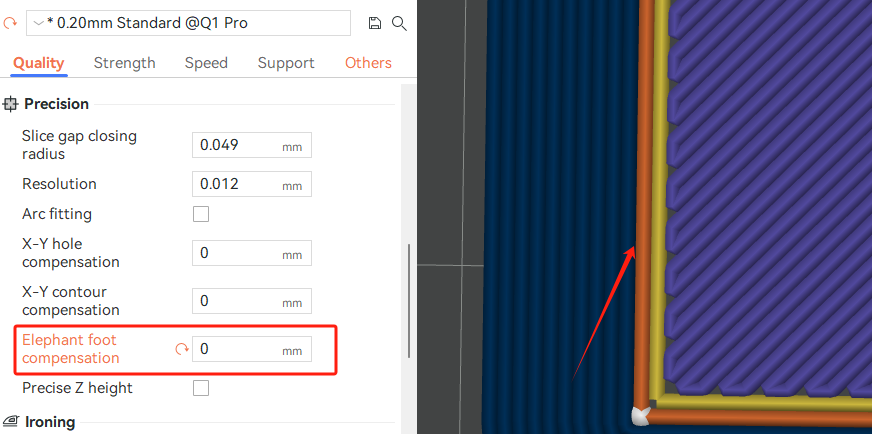

You can turn it on in the Process - Quality - Elephant foot compensation.

Slice comparison before and after enabling elephant foot compensation.

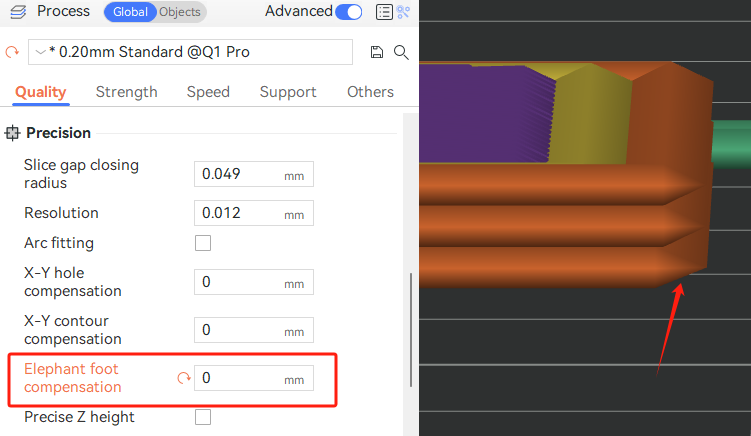

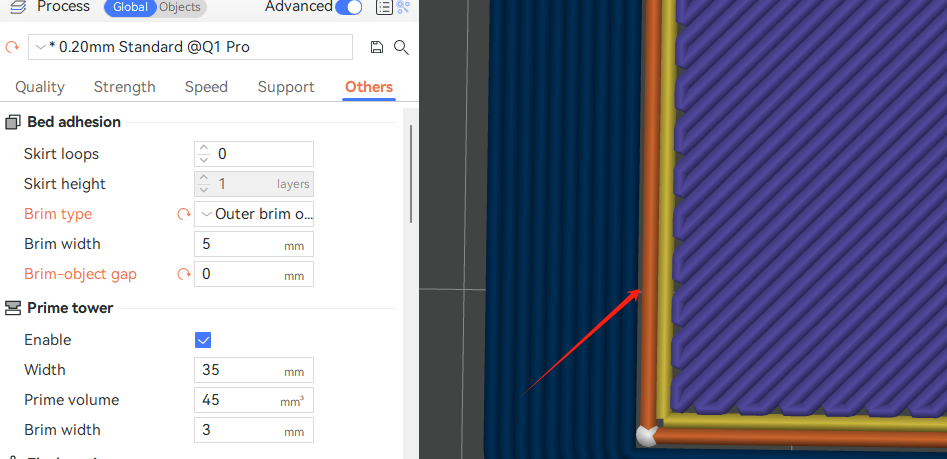

¶ When foot compensation is enabled, Brim does not fully fit the model on the preview page

When you enable Brim and set the "Brim-object gap" to 0mm and find that Brim is still not fully connected to the model, it may be caused by the elephant foot compensation. If you want Brim to fully fit the model in the preview page, you need to disable elephant foot compensation.

¶ The conflict between Brim and elephant foot compensation

When you enable Brim and set the 'Brim object gap' to 0mm, you find that Brim is not fully connected to the model, which may be caused by elephant foot compensation. If you want Brim to fully fit the model, you need to disable elephant foot compensation. For details, please refer to Brim.