¶ Layer height

Height of the individual slices/thickness of each layer. Layer height is the main factor affecting both:

- print time

- vertical resolution

By choosing taller layer heights you can significantly shorten the print time at the cost of more visible layers. On the other hand, choosing a small layer height (e.g. 0.10 mm) will result in extra detail at the cost of longer print times.

Generally, we do not suggest going lower than 0.10 mm as the improvement in print quality with 0.07 or 0.05 mm layers is relatively minor with significantly longer print times.

Keep in mind, that layer height changes only the vertical resolution. For example, an embossed text parallel with the print bed will look the same regardless of the layer height. If you’re looking for increased resolution in the XY plane, check nozzles with a different diameter.

The layer height should be below 80% of the nozzle diameter (e.g. the maximum layer height with a 0.4 mm nozzle is about 0.32 mm). The layer height cannot be higher than the nozzle diameter, QIDISlicer will display an error message if you try to input such a value.

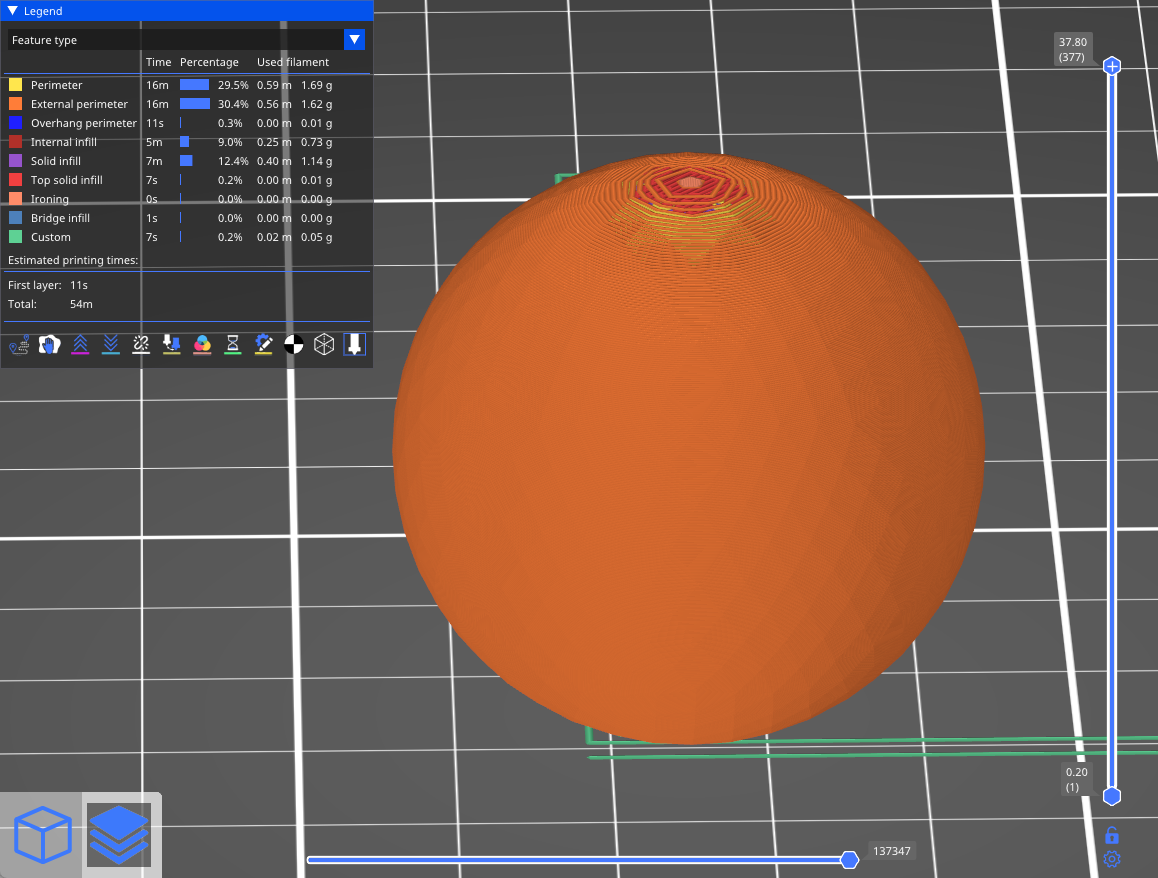

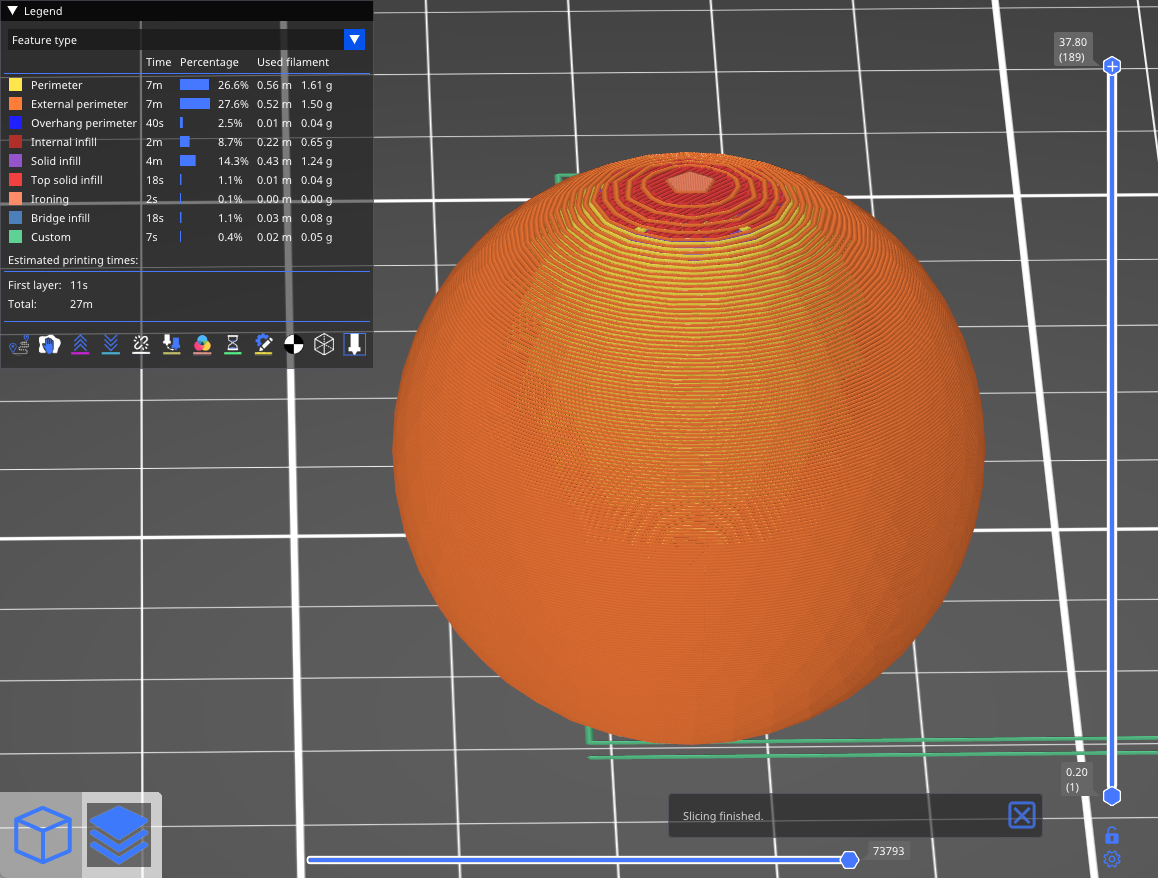

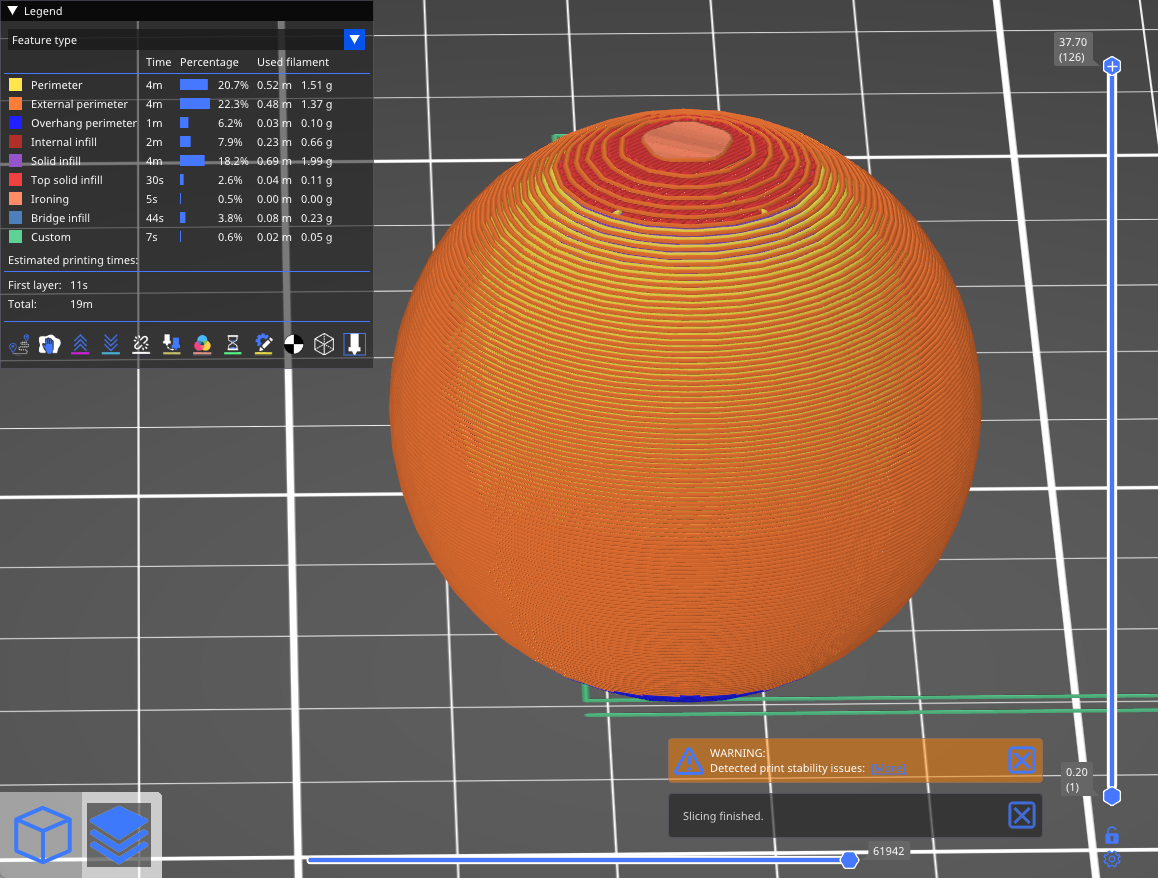

| Layer height : 0.1mm | Layer height : 0.2mm | Layer height : 0.3mm |

|

|

|

¶ First layer height

The default first layer height is 0.2mm, if you wish to print a thicker first layer to increase the adhesion of the printer, you can increase its value, but try not to exceed 70% of the nozzle size.

¶ Perimeters

Defines the minimum number of outlines that form the wall of a model. The default value for Perimeters is 2.

The strength of a model is mostly defined by the number of perimeters (not the infill). If you want a stronger print, increase the number of perimeters.

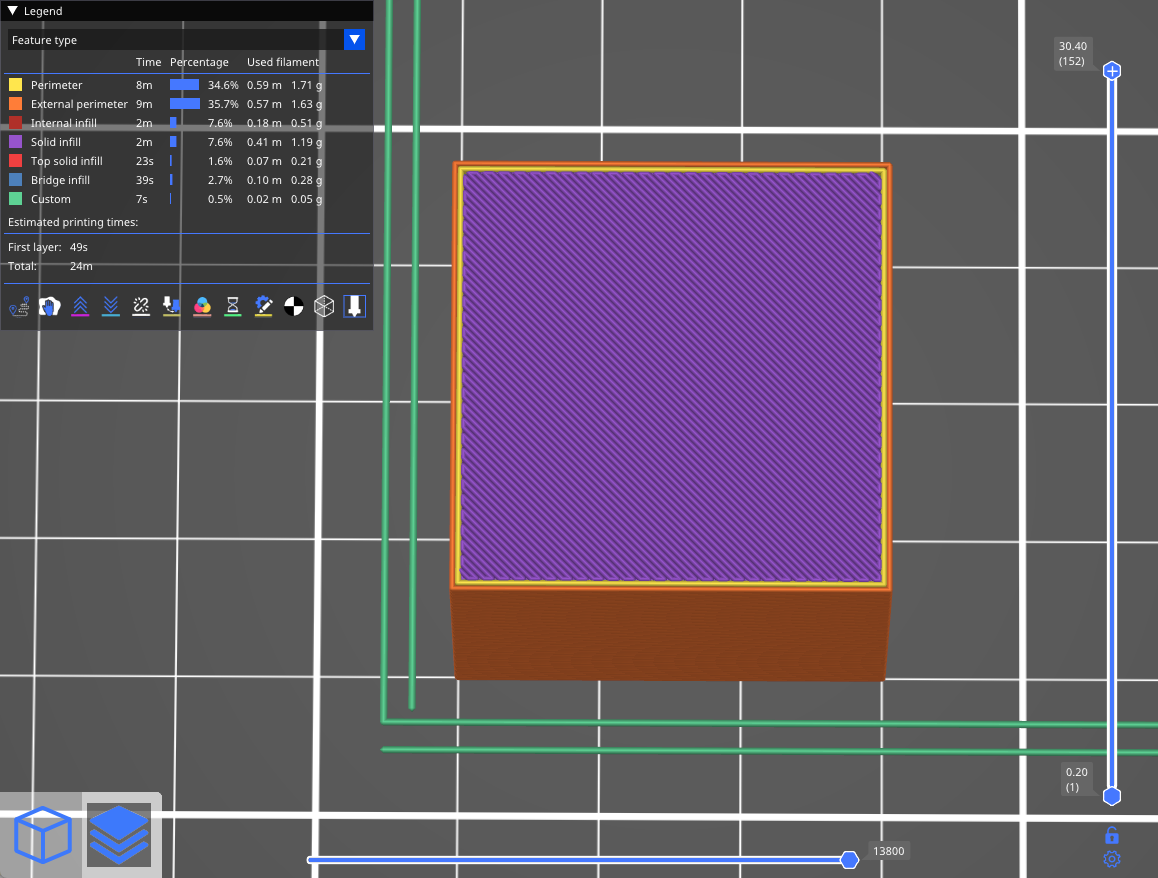

| Perimeters : 2 | Perimeters : 4 | Perimeters : 8 |

|

|

|

¶ Spiral vase

When printing any model with a single outline, there will always be a small flaw where the printer advances to the next layer. At this position, the printer stops, raises the Z height to layer height, and starts a new circle, creating an unsightly "scar" on the side of the model.

When the number of layers changes, the spiral vase does not have any points like this, except for the bottom layer.

When vase mode is activated, the following parameters are set automatically

- perimeters : 1

- infill : 0%

- disabled top solid layers

- disabled supports

- disabled ensure vertical shell thickness

Only one object at a time can be printed in the vase mode. If you had multiple objects on the print bed, it would be impossible to print them continuously. You can get around this limitation by enabling Sequential printing.

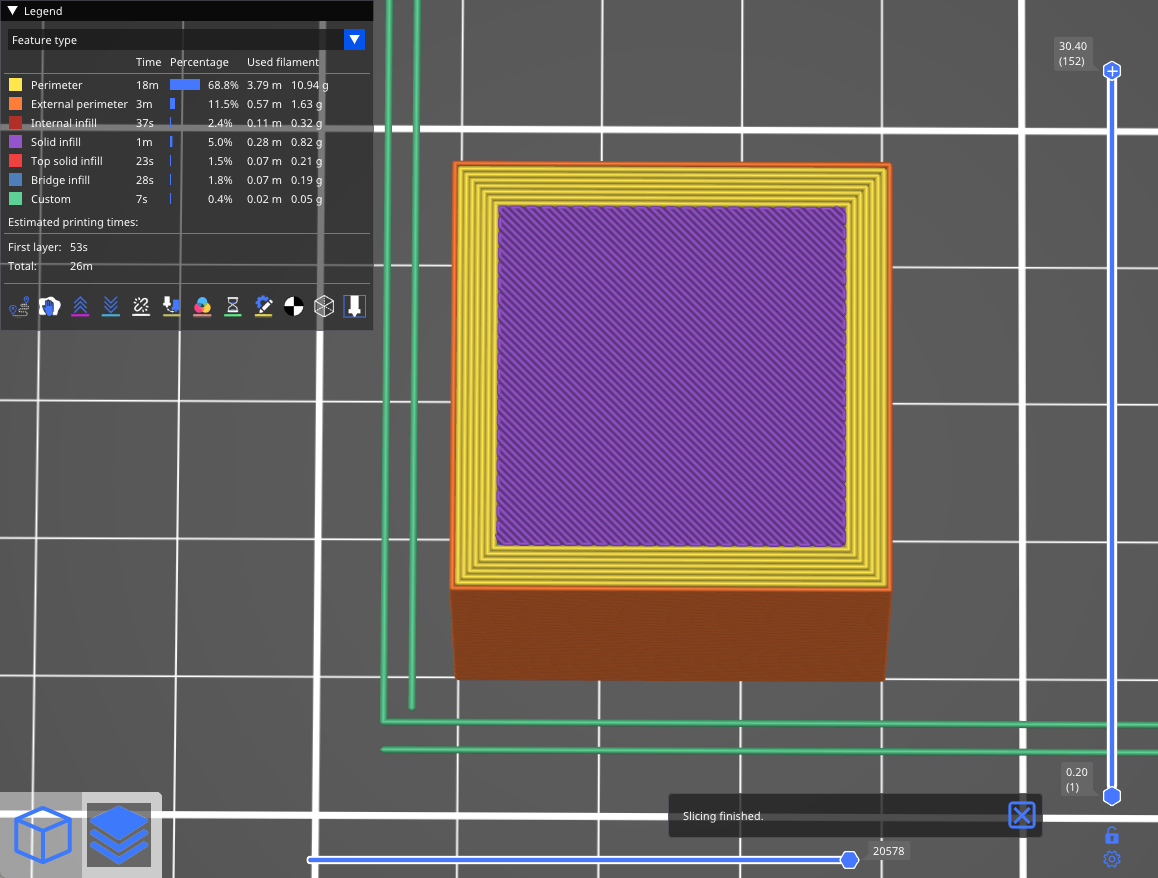

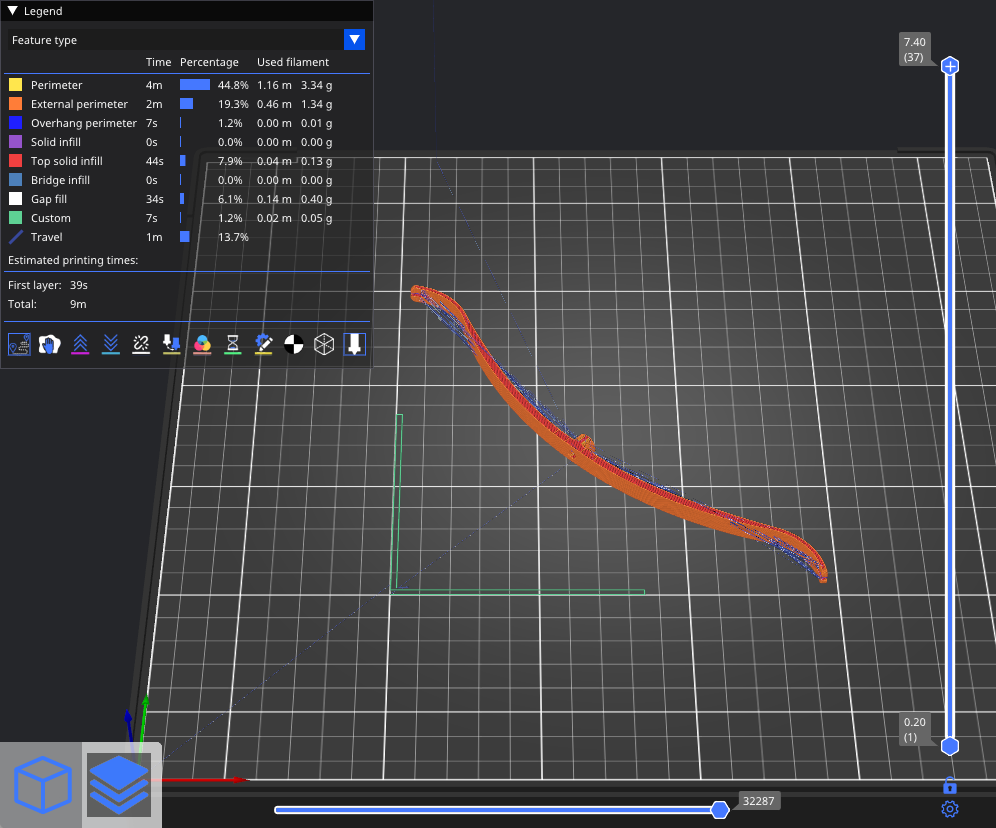

¶ Horizontal shells

¶ Solid layers

The bottom and top parts of models are usually filled with solid layers (100% infill).

You can set how many top and bottom layers you wish to print. You can also set a minimum wall thickness, which is especially useful when using the variable layer height function. The tooltip below these settings will update with every change, giving you a better idea of the resulting top/bottom wall thickness.

Setting the top or bottom solid layers to 0 overrides the minimum wall thickness. So you don't have to set the minimum wall thickness to 0 as well to get top or bottom layers.

¶ Quality

¶ Extra perimeters if needed

Add more perimeters when needed for avoiding gaps in sloping walls, QIDISlicer keepsperimeters ubtil more than 70% of the loop immediately above is supported.

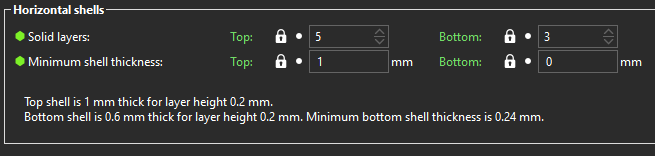

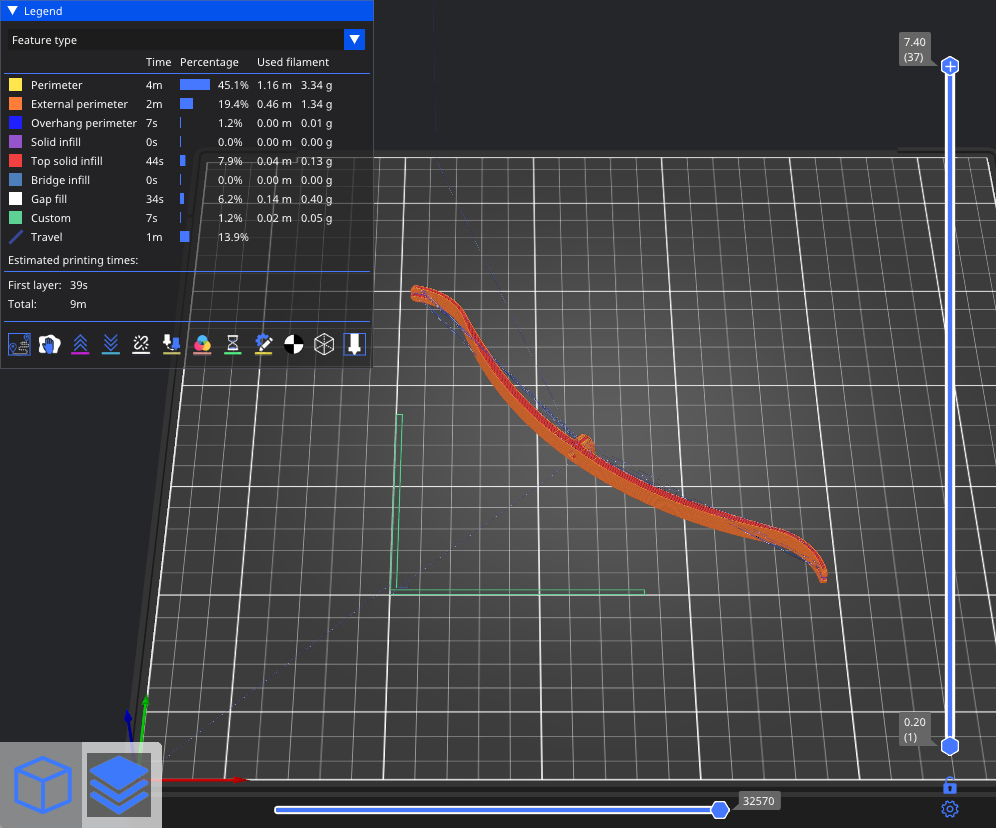

¶ Avoid crossing perimeters

Avoid crossing perimeters is an algorithm to minimize crossings of external perimeters during travel moves, which reduces stringing (especially with Bowden extruders) and improves overall print quality.

Enabling this feature slows down the G-code generation and increases print time somewhat (time increase varies between models).

If the detour is longer than the Max detour length, avoid crossing perimeters will not be applied for this travel move. You can use absolute values in millimeters, a percentage of the travel move, or set it to 0 to disable Max detour length check.

| ON | OFF |

|

|

¶ Detect thin walls

By default, every wall consists of outside and inside perimeters (a minimum of two perimeters for thin walls). If there is enough space, an infill pattern fills the void between these inside/outside perimeters.

Enabling Detect thin walls generate a single perimeter that works as both an inside & outside shell. This will help to capture tiny details. However, walls thinner than a single perimeter extrusion width will likely still be ignored.

This feature is automatically disabled if the Arachne perimeter generator is active, as it already automatically adjusts for thin walls.

¶ Thick bridges

When this function is enabled, when the bridge part is printed, lines and thick line segments will be printed to act as the bottom bridge; If this feature is turned off, the line segment of the printed bridge will use the current layer height.

| ON | OFF |

|

|

¶ Detect bridging perimeters

Enables bridging flow for overhangs and turns on the fan.

¶ Advanced

¶ Seam position

Determines the start point of each perimeter loop, and thus the position of the potentially visible vertical seam on the side of the object. Unless you're printing in the Spiral vase mode.

You'll find more information and pictures in the Seam position.

¶ Staggered inner seams

This feature causes the inner seams to be shifted backward based on their depth, forming a zigzag pattern. This creates a stronger part by avoiding that the seams align.

¶ External perimeters first

Perimeters will be printed from the outermost to the innermost ones instead of in the inverse order.

This parameter may help with dimensional accuracy since the outer perimeter is laid down first and any extra filament extruded when printing following perimeters is pressed back away from the outer wall. On the other hand, the surface may be slightly less smooth.

¶ Fill gaps

Enables filling of gaps between individual perimeters and between the innermost perimeter and infill.

¶ Perimeter generator

Allow you to switch between the Arachne (default) and the Classic perimeter generator. The Arachne perimeter generator automatically adjusts the extrusion width of perimeters as needed. For most prints the Arachne perimeter generator is superior, but for some functional prints where the accuracy of concave corners is important, the classic perimeter generator may be better.

See Arachne perimeter generator for more information.

¶ Only one perimeter

-

Top layer profile

Optional: Disable, top surface only, all top surfaces -

First layer single layer outline

When this function is turned on, the main function is to set the outline to 1 when printing the top surface, and the top fills more space for the pattern.