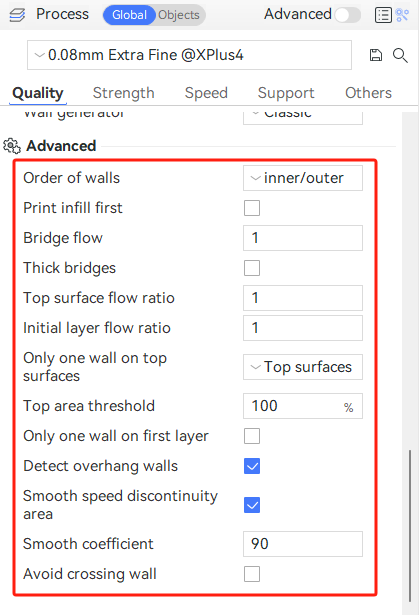

In QIDIStudio, you can set some advanced parameters related to print quality in Process - Quality - Advanced.

Note: Some parameters will only be displayed if you enable "Developer mode" in Preference.

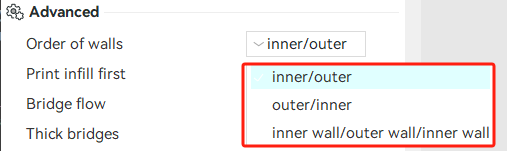

¶ Order of Walls

This parameter is used to adjust the print order of walls. There are currently three options.

- inner/outer

- outer/inner

- inner wall/outer wall/inner wall

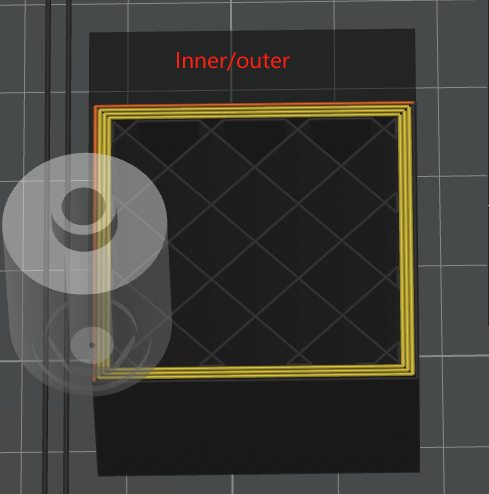

¶ Inner/outer

The printer prints from the inside to the outside, that is, the innermost wall first, and the outer wall in the end. This is also the default order, as shown below.

If the model has overhanging parts, this sequence will provide better print quality. This is because, before the printer reaches the overhanging sections, the inner wall on one side of the outer wall is already printed. The inner wall ensures that the overhanging sections adhere properly, reducing surface defects caused by warping or sagging of the overhanging parts. The specific differences are shown as follows.

If orders of outer/inner or inner/outer/inner are used, the outer wall(orange lines) is completely overhanging with no adhesion on both sides, resulting in poor overhang quality.

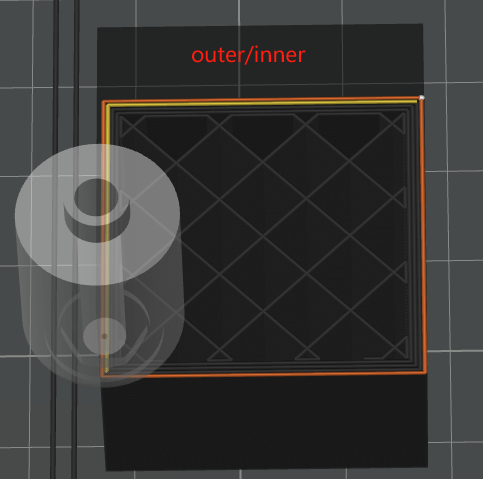

¶ Ouer/inner

The printer prints from the outside to the inside, the outermost wall first, and the innermost wall in the end. When printing in this order, the seams on the surface of the model may be more obvious. However, if the printer prints the outer wall first, the can cool down and solidify first, which can minimize the imperfections and interlayer patterns on the surface caused by the squeezing or contraction of the lines inside the model.

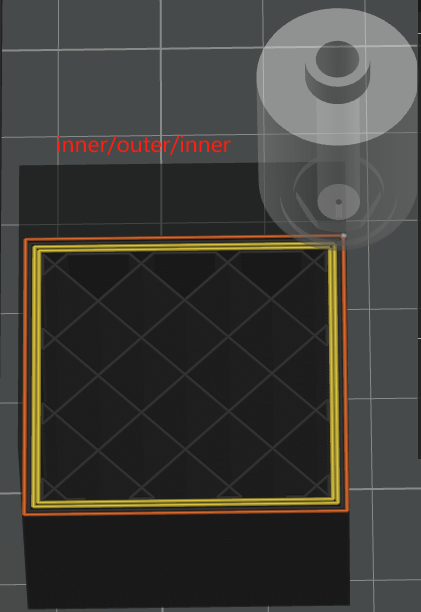

¶ Inner/outer/inner

The printer first prints from the innermost wall from the inside out. After printing the second-to-last inner wall, the printer starts printing the outer walls. Finally, the inner wall adjacent to the outer walls are printed, as shown in the following figure.

Printing in this order, there will be an empty space between the outer walls and the other finished inner walls, which minimizes the effect of shrinkage on the inner walls. Moreover, other printed walls have already cooled down and solidified for some time, so they can minimize the squeezing or shrinkage on the inside that affect the outer walls and thus affecting the appearance of the model.

¶ Print infill first

The infill will be printed first, followed by the inner and outer walls.

“Infill” here refers to all horizontal lines, including sparse infill, internal solid infill, top surface, bottom surface, and bridge.

¶ Bridge flow

With this setting on, the actual bridge flow will be calculated by multiplying the original bridge flow by this factor. For details, please refer to: Bridge settings.

¶ Thick bridges

Enable thick bridges. For details, please refer to: Bridge settings.

¶ Top surface flow ratio

For the top surface, the actual flow ratio is calculated by multiplying the original flow ratio by this factor. This factor affects the amount of filament used for the top solid infill.

¶ Initial layer flow ratio

The actual flow ratio is calculated by multiplying the original flow ratio by this factor.

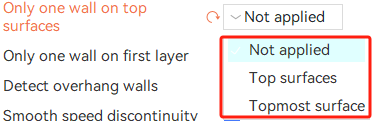

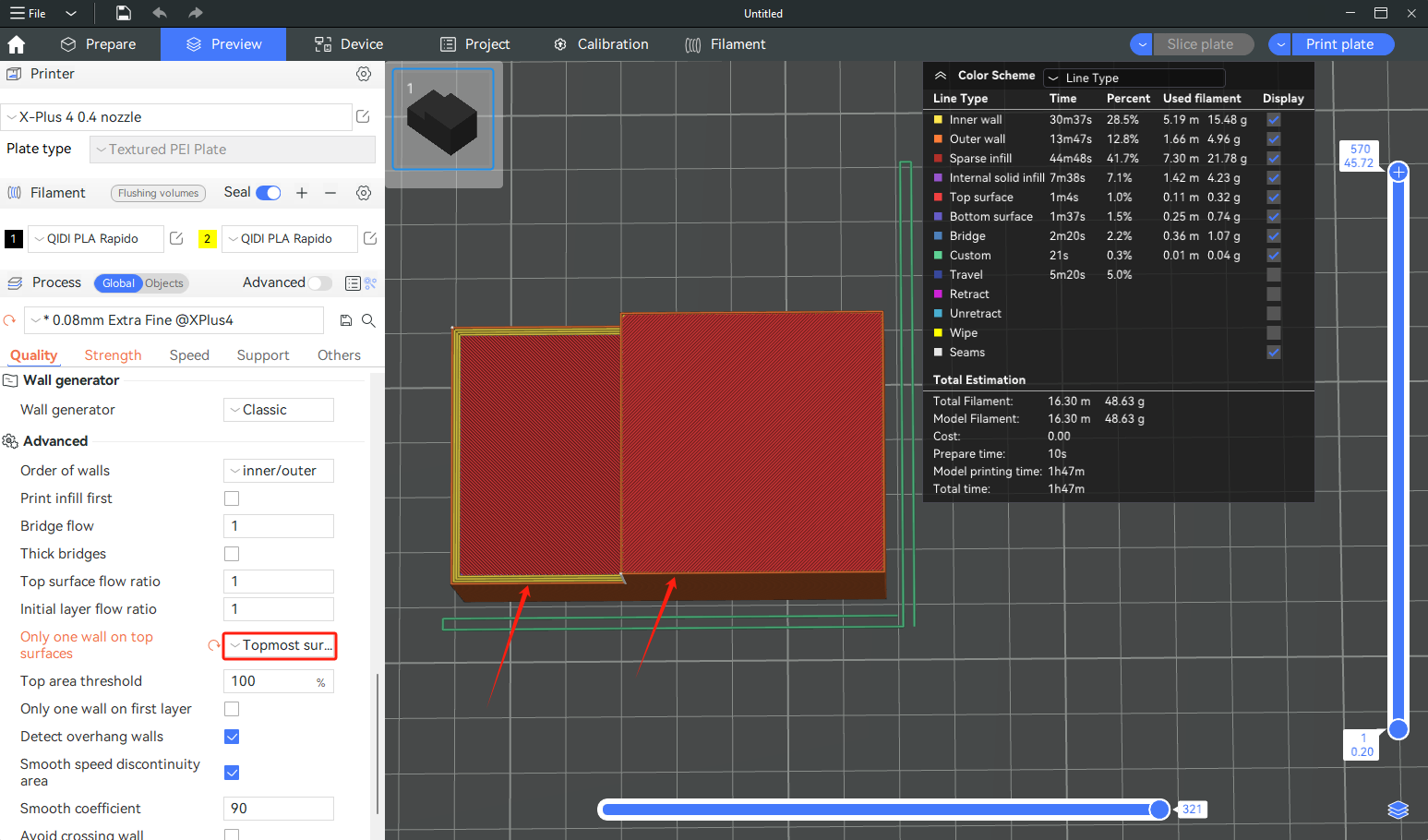

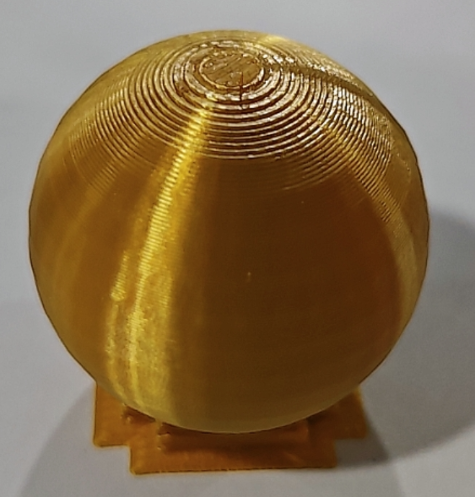

¶ Only one wall on top surfaces

With this option enabled, top surfaces will have only one wall, giving better appearance to top surfaces, especially for models with a flat top. This option is enabled by default. If you disable this option, the number of walls on top surfaces will be the same as the number of wall loops set in Strength > Walls.

This option can work on both the top surface and the topmost surface. The top surface refers to all top surfaces of the model, and the topmost surface refers to the highest one of the object, as shown below.

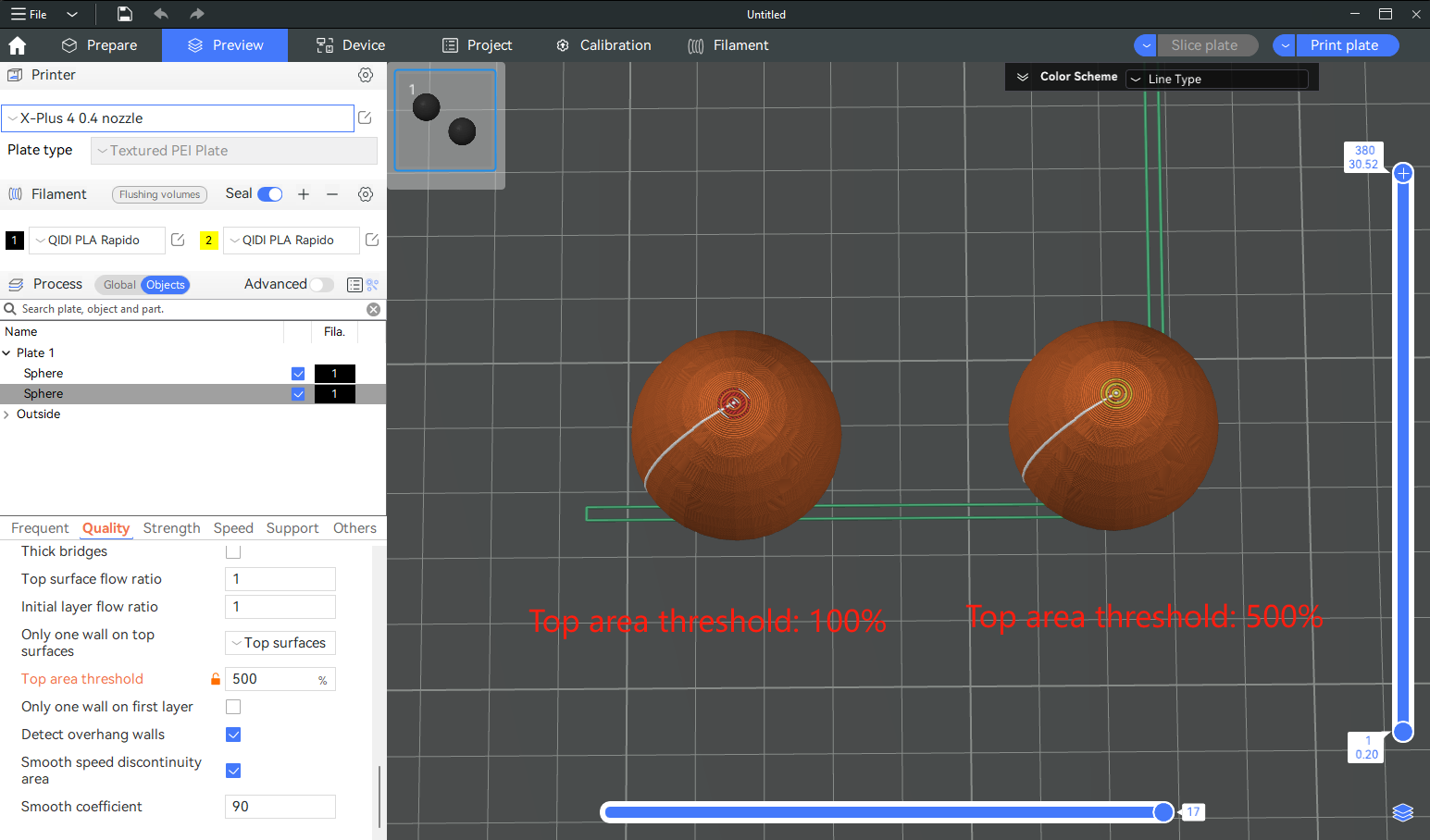

¶ Top area threshold

This parameter can be configured after only one wall on top surfaces is enabled. This parameter affects the area threshold for the area of the wall that forms a single layer of the top surface. If part of the top surface is covered by a higher layer, such as the top of a sphere, then that top surface will not be considered as a top surface if its width is less than this threshold.

This can be used to avoid triggering “only one wall on top surface” on narrow top surfaces (usually not the topmost surface). This threshold represents the percentage of line width. By increasing this value, smaller top surfaces are filtered out and still generated with the number of walls set in wall loop. However, this threshold does not take effect on the topmost surface.

| Top area threshold:100% | Top area threshold:500% |

|

|

¶ Detect overhang walls

This option detects the overhang angle of walls and applies different printing speeds. For walls with 100% overhang angle, the bridge speed will be applied. For details, please refer to: Slow Down for Overhangs.

If this option is disabled, the inner and outer walls will print using the inner and outer wall speeds in the speed settings. The differences are described below:

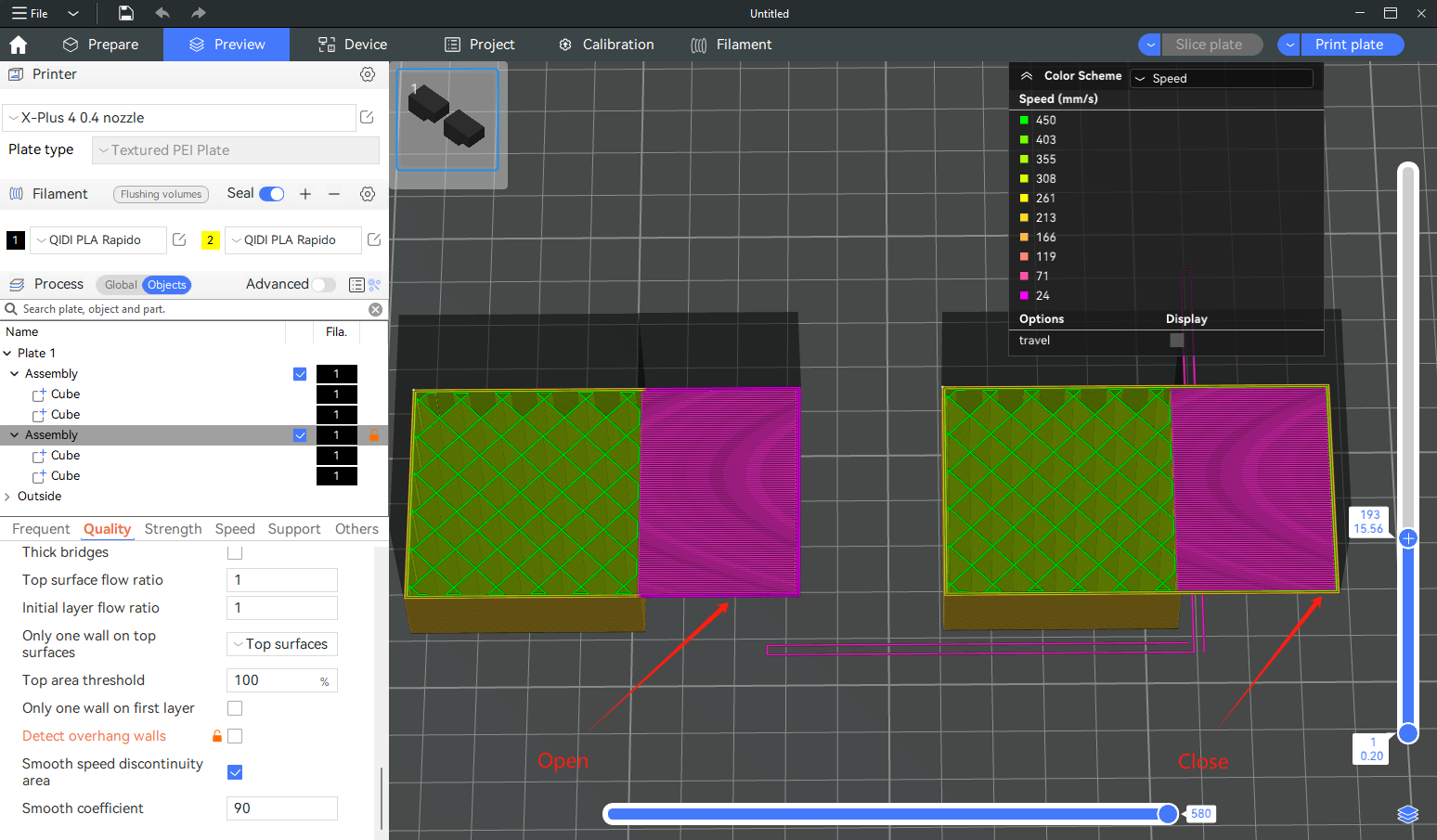

¶ Smooth speed discontinuity area

Overhanging and non-overhanging areas usually have large speed variations, so enabling this option can make speed transitions smoother to improve cooling. This option is enabled by default.

¶ Smooth coefficient

It is used to control the length of the smooth transition path. The smaller the value, the longer the area of the speed transition, which means that the speed transition is smoother. Appropriate adjustment of the smoothing coefficient can make the print quality of the overhang area better, and it is usually recommended to set in the range of 1 to 200.

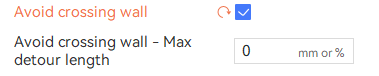

¶ Avoid crossing wall

Enabling this function allows the nozzle to not cross the outer wall as much as possible when traveling. This can minimize oozing that leads to stringing when crossing the outer wall when printing a layer print of one object.

Avoid crossing wall - Max detour length: When the detour length of a travel is greater than this value, this travel will not make a detour.

The detour length can be set as an absolute value, or as a percentage relative to the length of a straight travel (50 means 50mm; 50% means a percentage). This value represents the increased length of the detour compared to the normal travel. If the length exceeds the value, the detour will not be made, and the original straight travel will be performed.

Maximum detour length is 0 by default, representing no limit on the detour length, and all detours will be performed.