¶ Initial Startup Guide — QIDI Studio

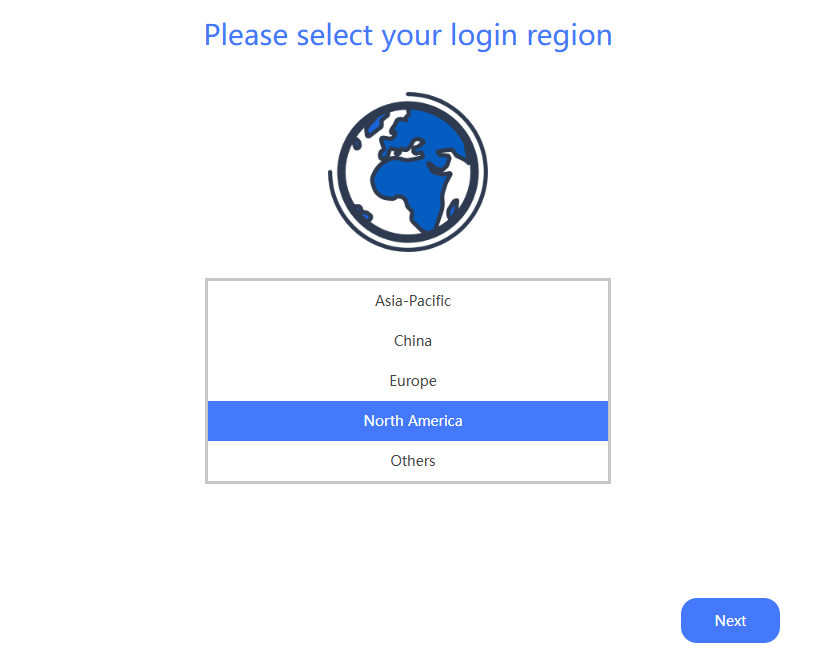

¶ Step 1 — Select region

Select the region where you are located (for example, North America).

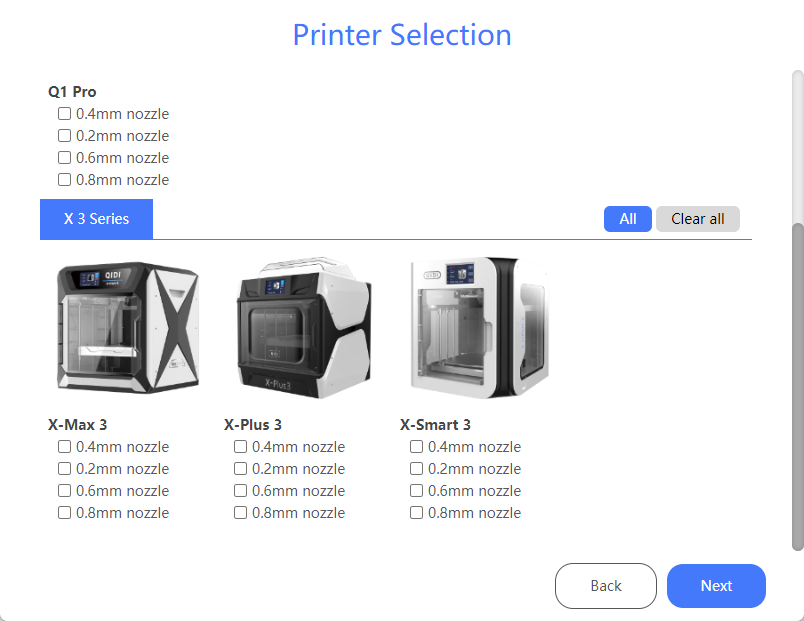

¶ Step 2 — Select printer

Select the printer model(s) you want to add.

You may select one or multiple printers.

These selections can be modified later from the printer menu.

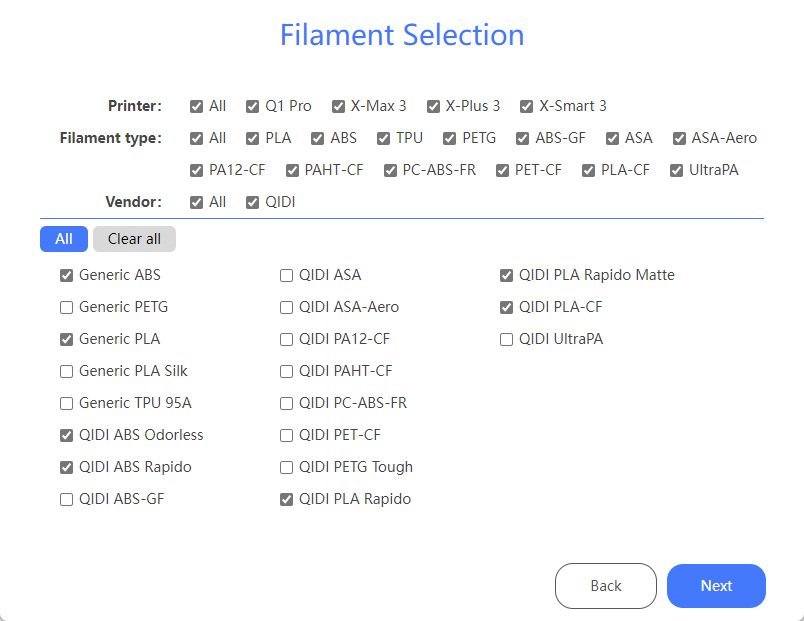

¶ Step 3 — Select filament

Select one or multiple filament types you plan to use.

The selected filament profiles will be saved in the Filament Presets list.

¶ First Print

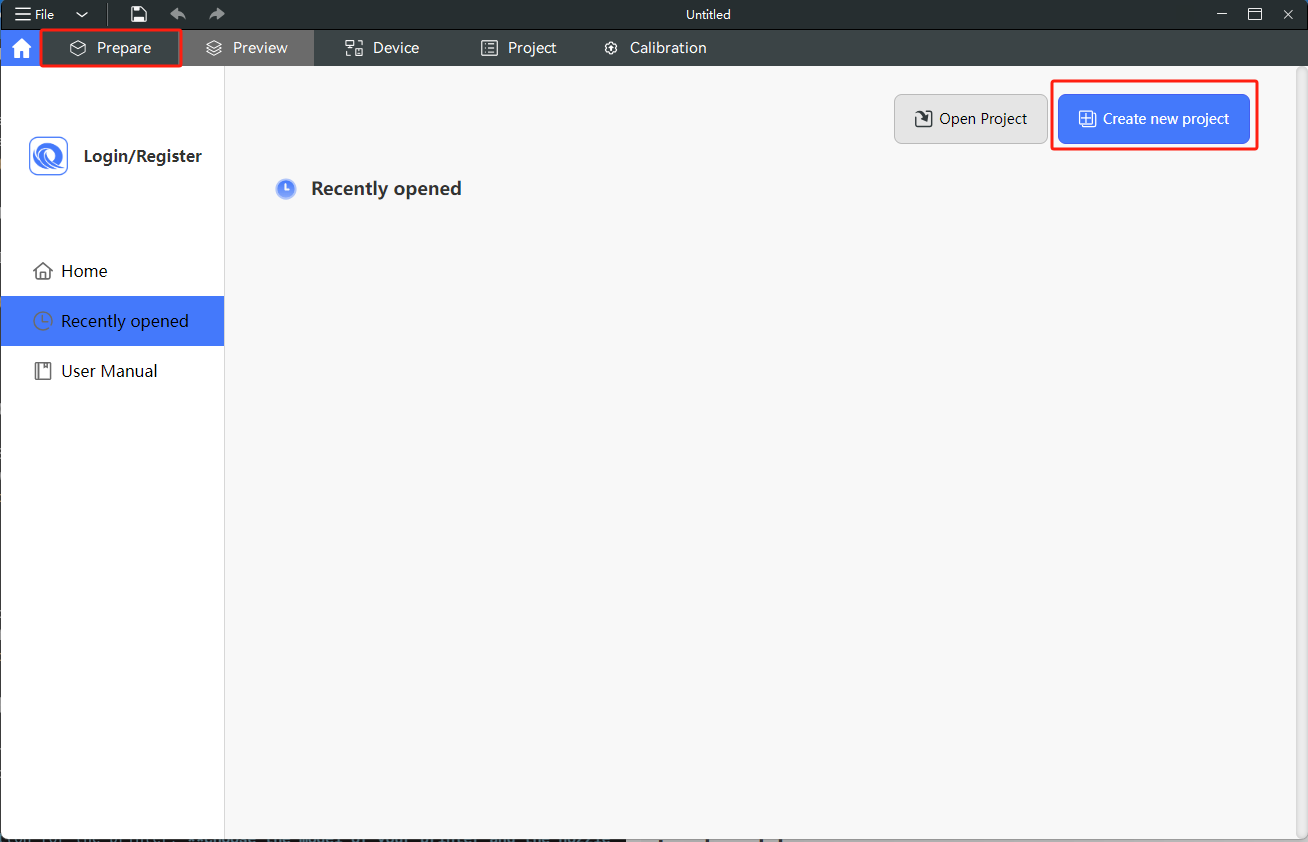

¶ Create a new project

When opening QIDI Studio for the first time:

- Click Create New Project, or

- Click Prepare

to start a new project.

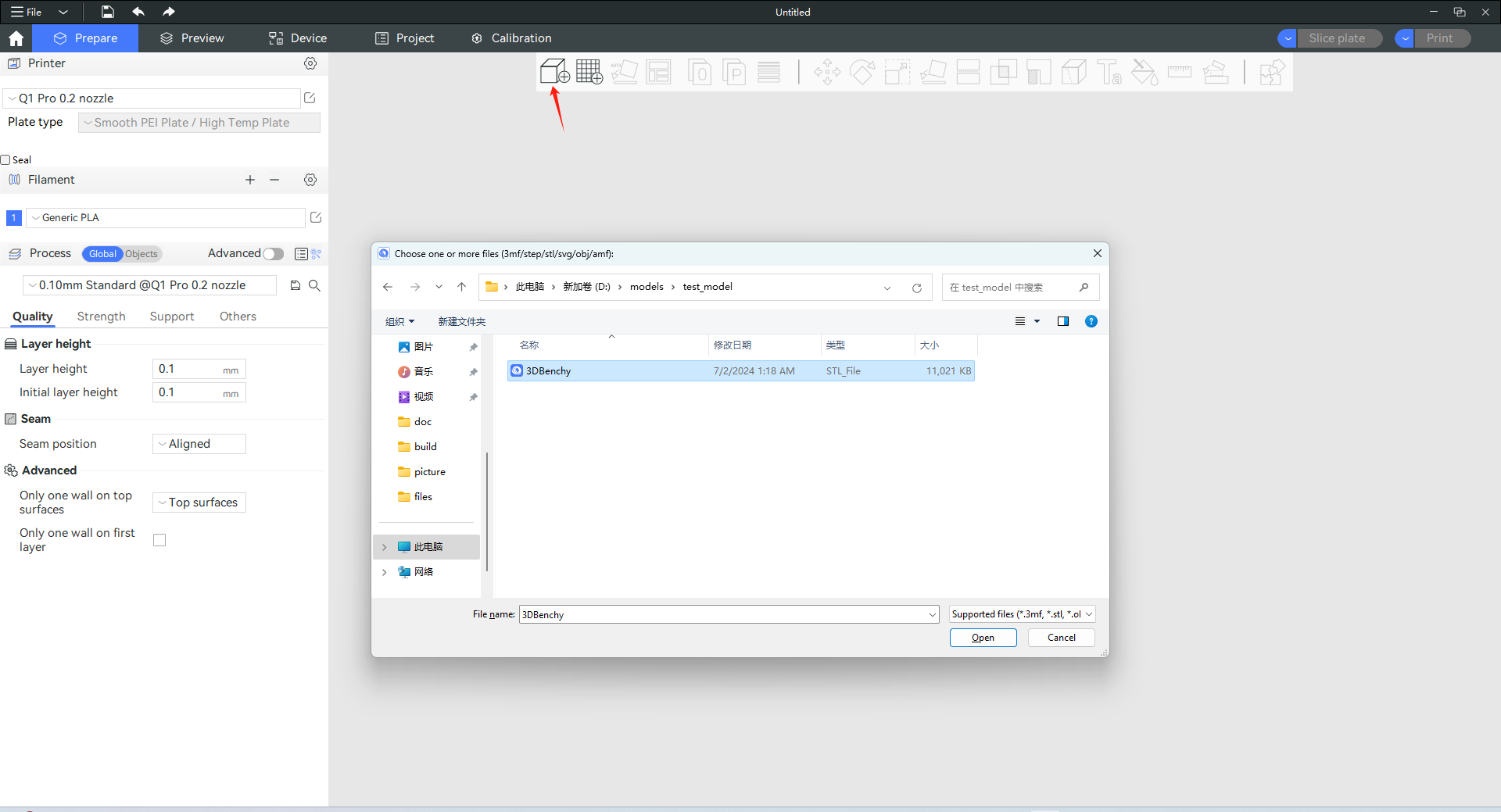

¶ Load a model

Click Add in the top menu bar, or use the shortcut Ctrl + I, to open the file import dialog.

Select the model file and click Open.

Supported file formats:

.3mf · .stl · .step · .amf · .obj

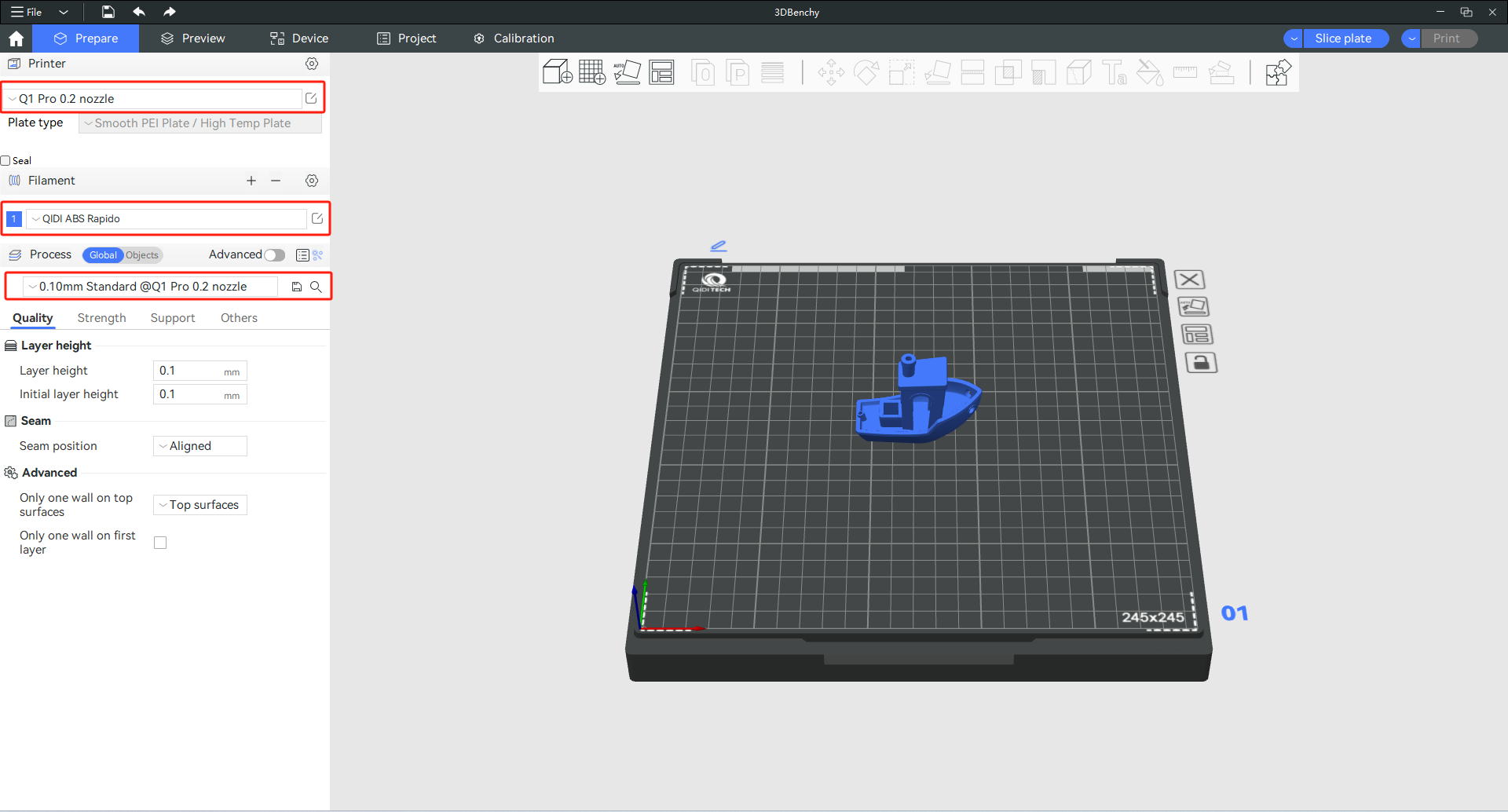

¶ Select printer, filament, and process presets

Before slicing, configure the required presets.

Proper preset selection ensures correct hardware configuration and print quality.

¶ 1. Select printer preset

Click the printer dropdown and:

- Select your printer model

- Select the correct nozzle size

If your printer is not listed, add or remove it using the gear icon in the printer list, or by selecting/removing it from System Presets.

¶ 2. Select filament preset

Click the filament dropdown and select the filament type being used.

¶ 3. Select process preset

Click the process dropdown and select the desired layer height.

If you want to create a custom preset, refer to:

How to Create Custom Preset

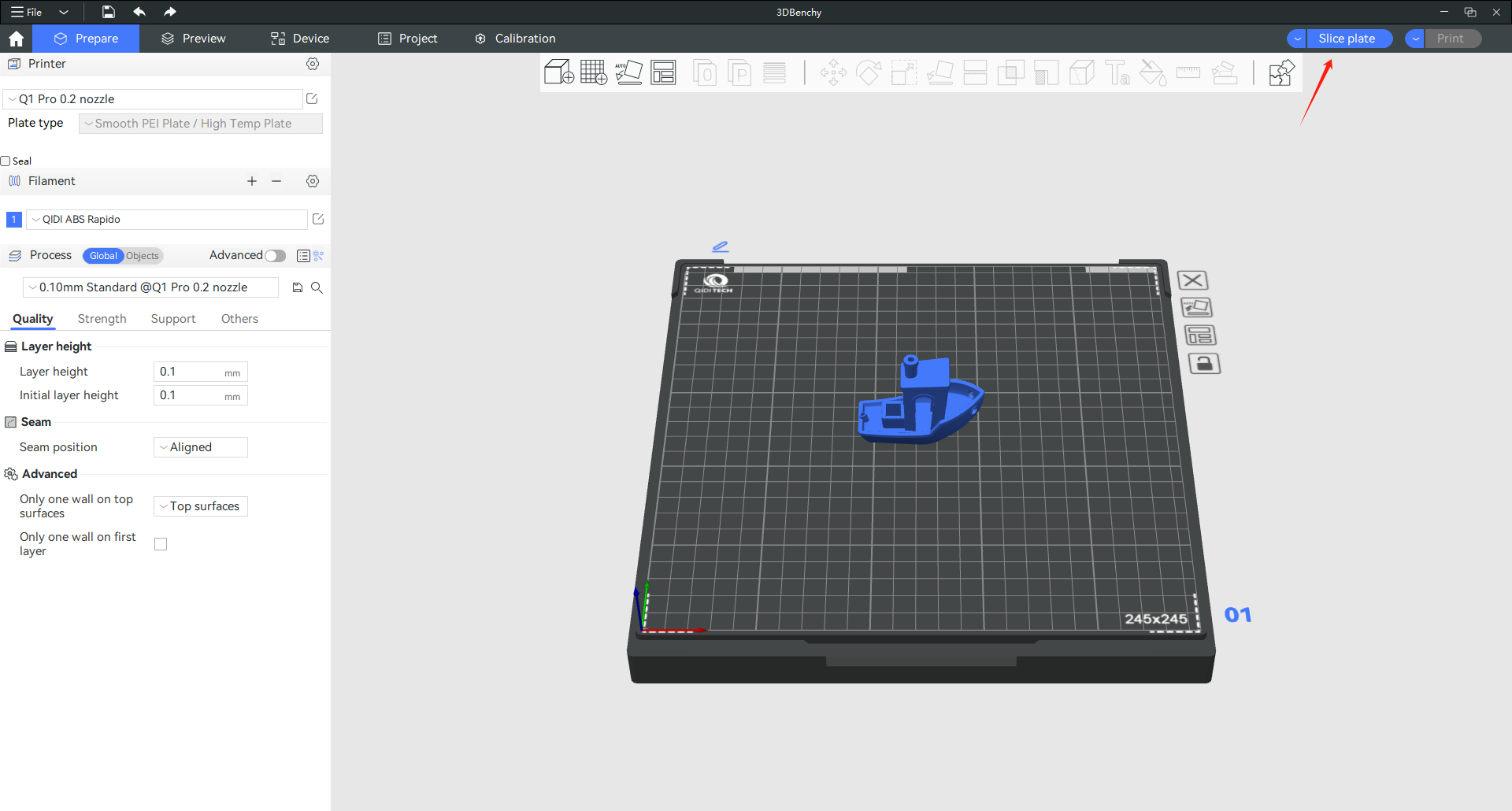

¶ Slice the model

After configuring the presets, click Slice Plate in the top-right corner.

After slicing:

- A G-code file is generated.

- QIDI Studio switches to the Preview tab.

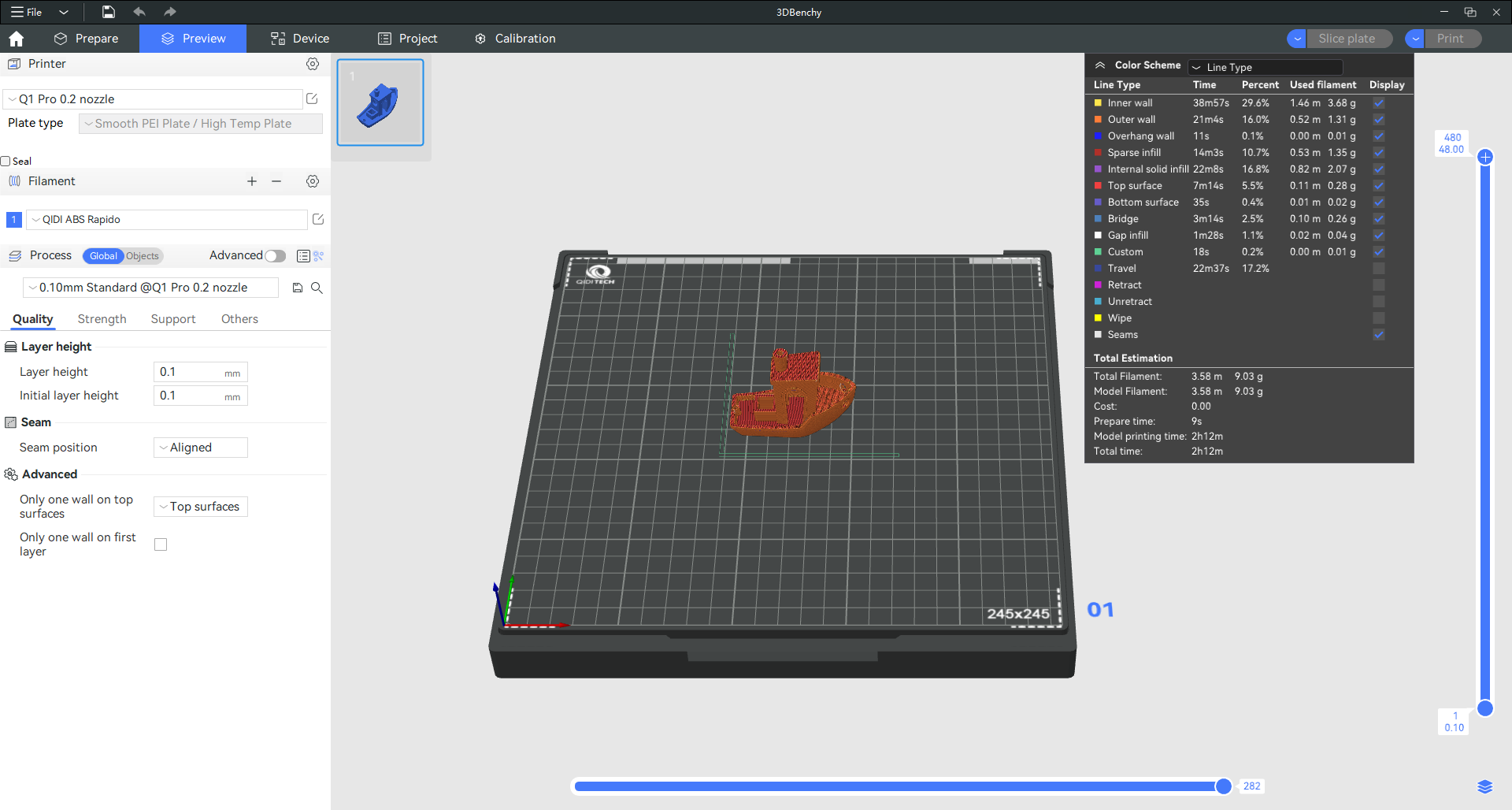

The Preview screen displays:

- Model appearance after slicing

- Filament usage

- Estimated print time

Use the progress sliders to preview specific print layers.

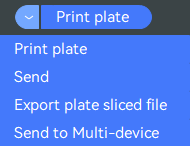

You can transfer the generated G-code file to the printer using one of the following methods:

- Print Plate

- Send

- Export Plate Sliced File

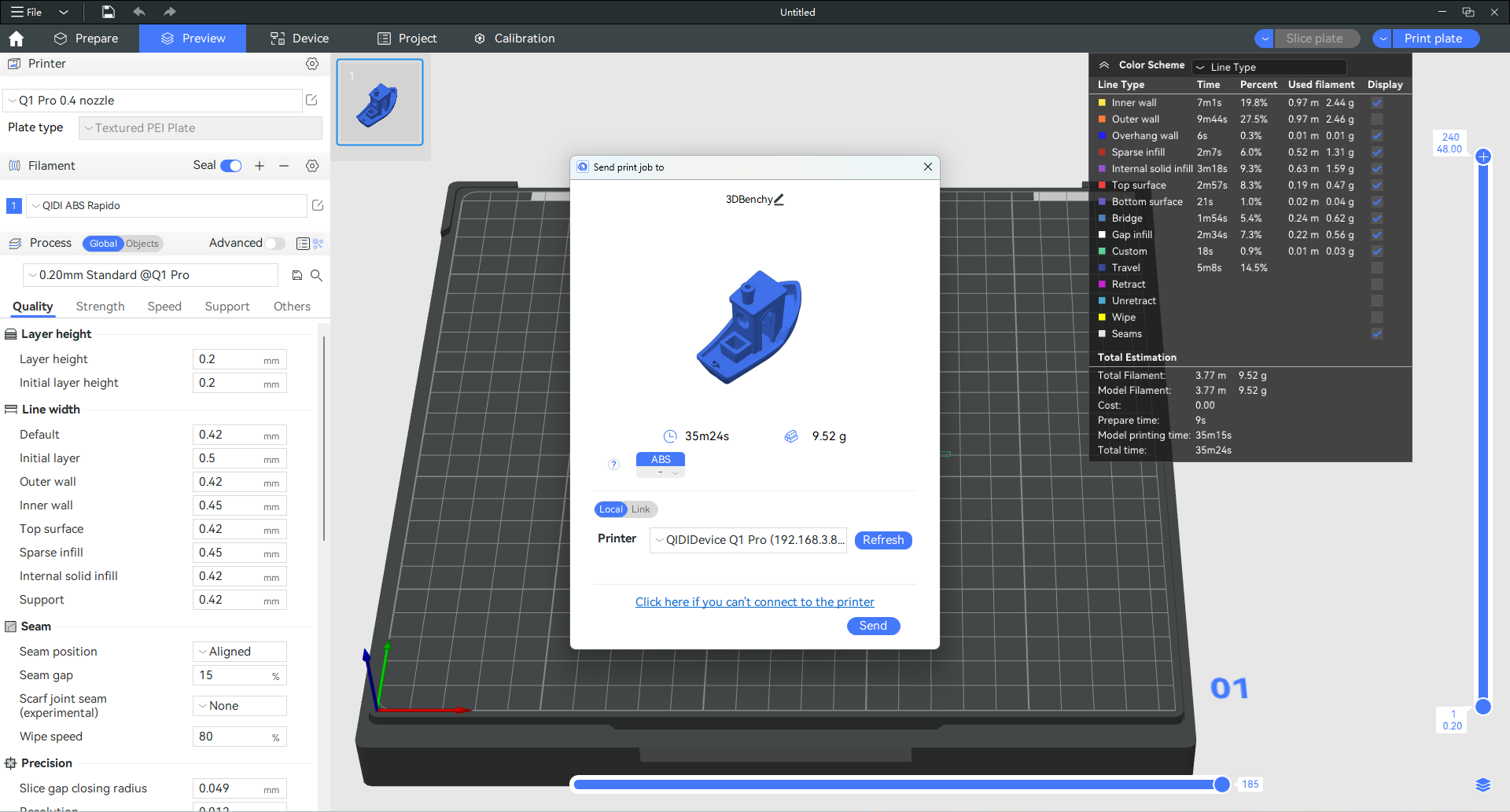

¶ Send to printer (Network)

After slicing:

- Click Print Plate in the pop-up window, or

- Click Send

The printer will begin printing automatically after receiving the file.

Note: To transfer files over a network, the printer must be connected.

For details, see:

Connect a Physical Printer to the Fluidd Interface

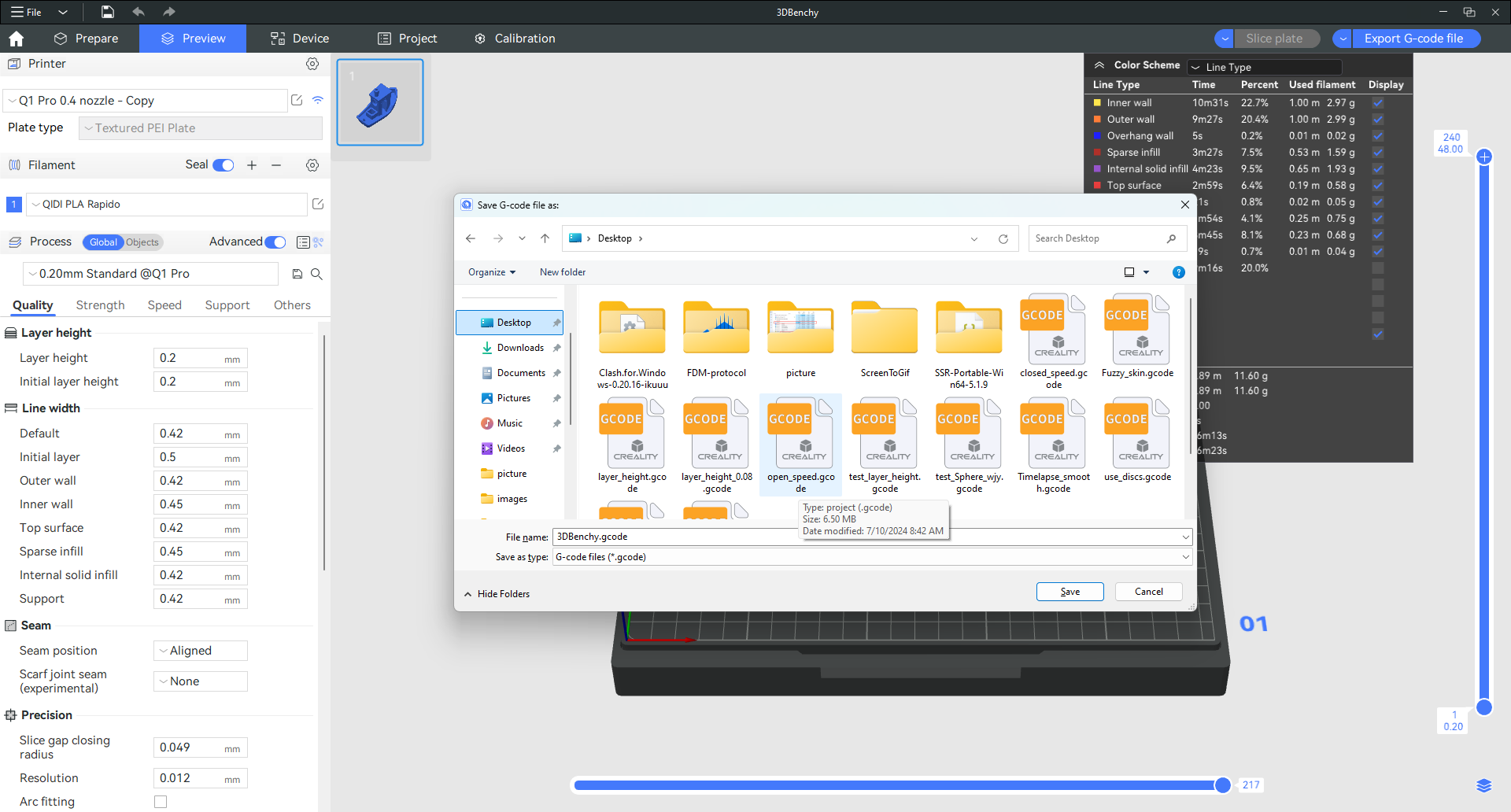

¶ Use USB flash drive

You may also:

- Export the G-code file locally.

- Copy it to a USB flash drive.

- Insert the USB drive into the printer.

- Select the model manually on the printer screen.

¶ Important

Ensure that the software configuration matches the printer hardware configuration before printing.

Examples:

- Filament type

- Printer preset

- Nozzle size

Configuration mismatches may cause print failure or nozzle clogging.